The Value of Mass Finishing, Shot Blasting for Aerospace and Medical Applications

The choice between mass finishing and shot blasting for CNC-machined parts depends on the specific requirements of the application.

Colin Spellacy

Head of Sales, Rösler UK

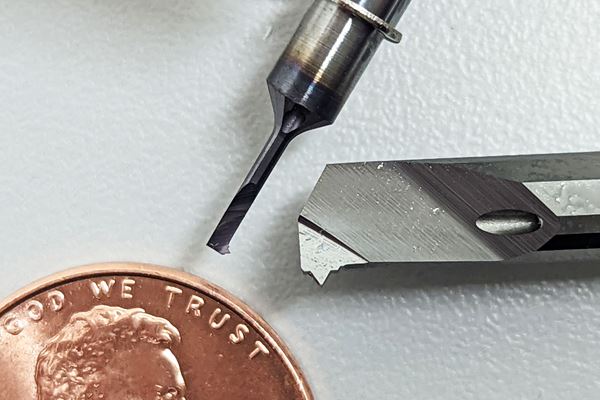

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

Bar Feeder Designed with Swiss-Types in Mind

New technology enables this bar feeder to fully support the bar pusher and stock from inside the unit all the way to the spindle of a sliding headstock lathe.

German Project Yields Three New Medical Machining Processes

Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

CNC Rotary Transfer Machine Features Ballscrew Electromechanical Tooling Units

A CNC rotary transfer machine, a newly developed machine platform, is said to offer high rigidity, flexibility and accuracy for a range of high-volume, precision-machining applications.

Reaming as an Alternative to Single-Point Boring

Using slip yokes as an example, reaming through holes can be more efficient and effective than single-point boring operations.