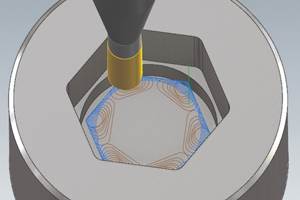

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

#micromachining

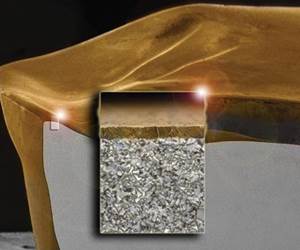

Kyocera Turning Inserts Provide Fracture, Wear Resistance

The KBN010 high-speed CBN grade gives users more flexibility, range, performance and tool life when turning hardened materials.

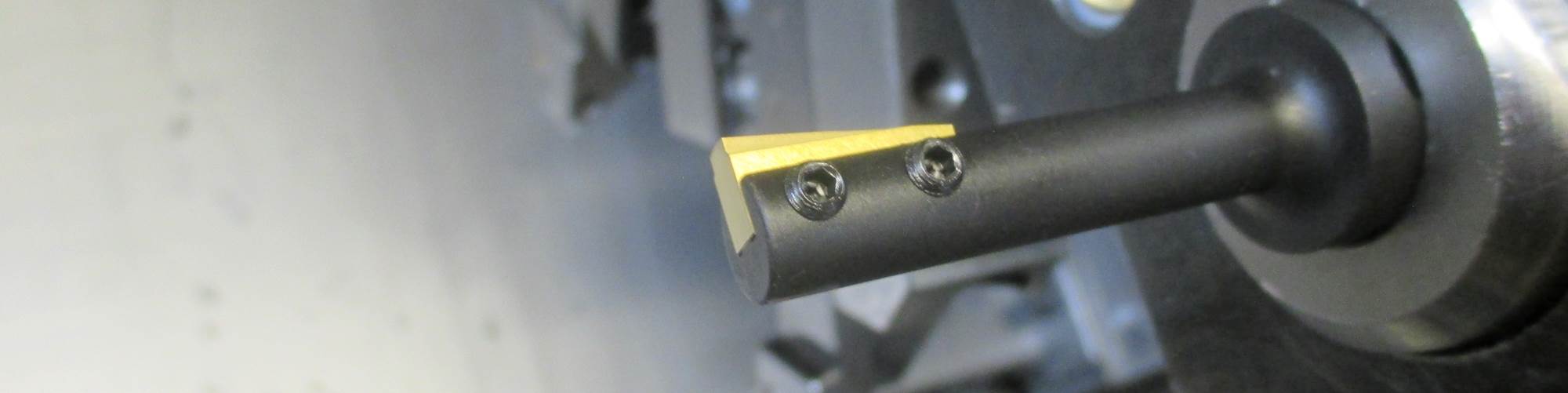

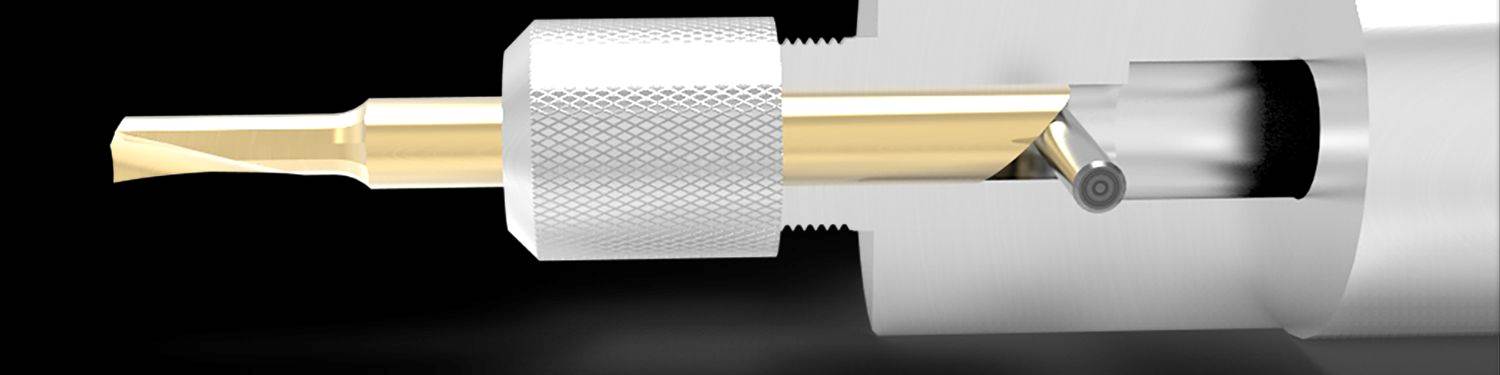

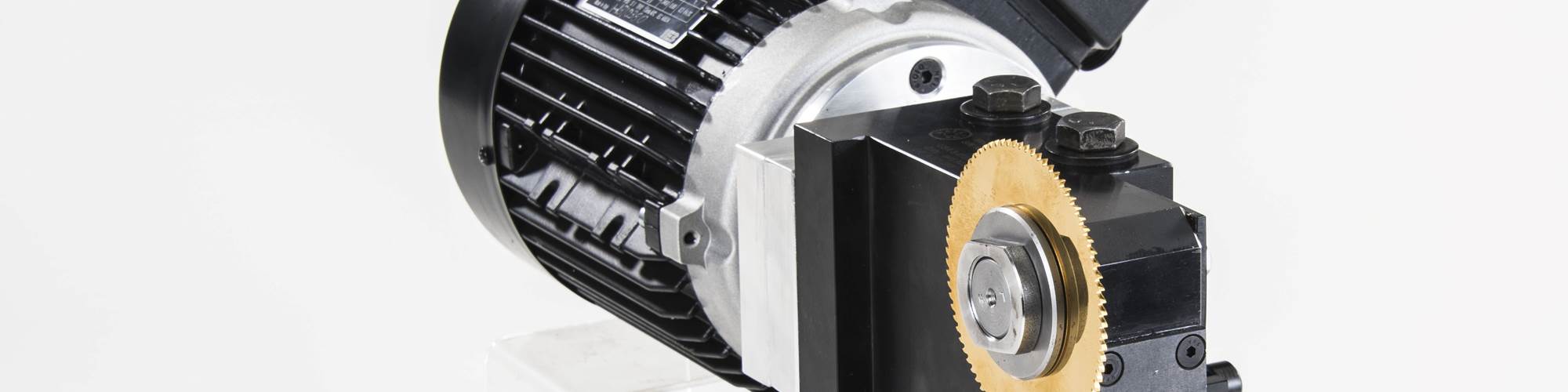

Tungaloy Boring Bar System Features Vibration Dampening

The BoreMeister boring bar system features a variety of exchangeable heads and shanks for internal turning, profiling, threading and grooving.

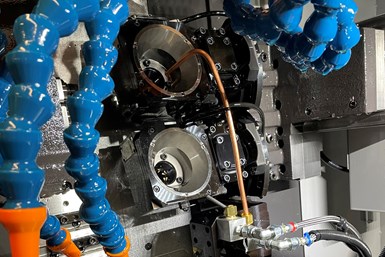

Walter Indexable Drill Inserts Provide High Wear Resistance

The WNN15 drilling grade features a hard substrate, which provides high cutting-edge strength and sharpness on indexable inserts.