Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Addressing Micro-Boring Challenges

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

#techbrief #micromachining

New Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

IMCO Carbide Tool Inc. End Mills for Faster Part Cycles

The M936 Pow-R-Feed series is designed to make various toolpath moves without slowing down, providing faster cycle times and more production.

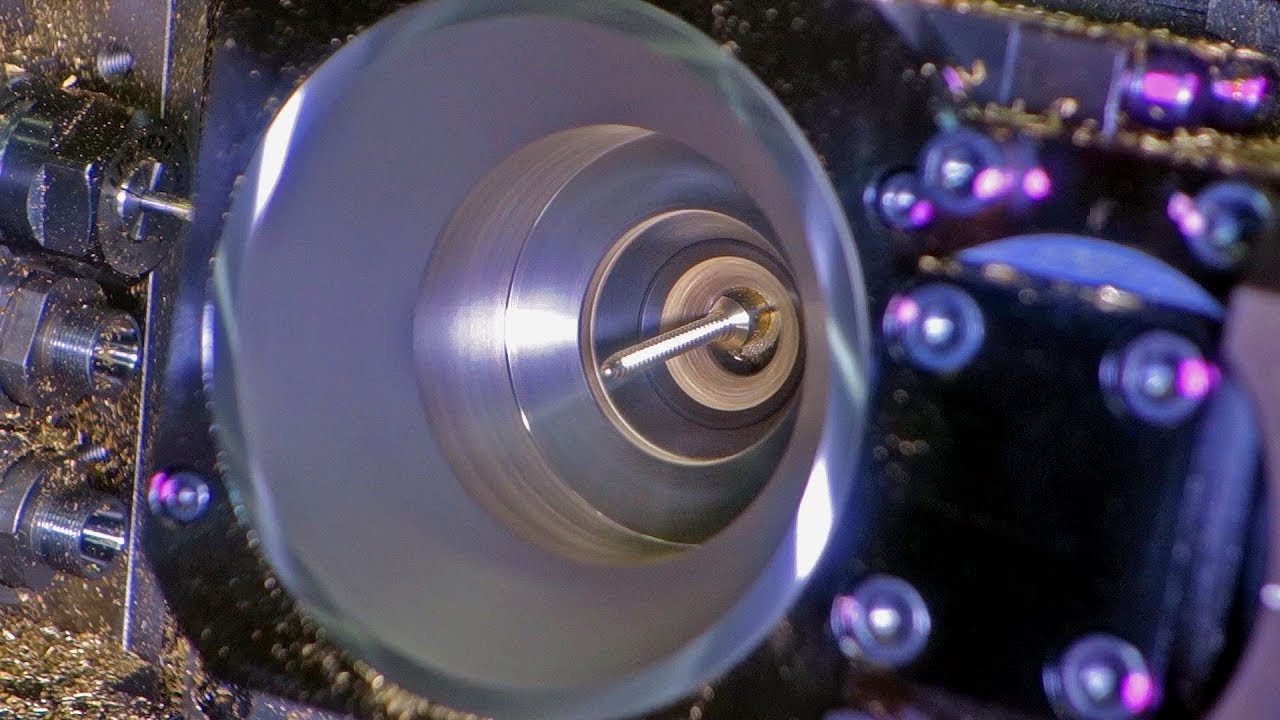

The Value of Dual Thread Whirling Units for Bone Screws

Dual thread whirling units on a Swiss-type enable it to produce medical bone screws with two different thread leads in one setup, eliminating the need for time-consuming, single-point threading.

#techbrief

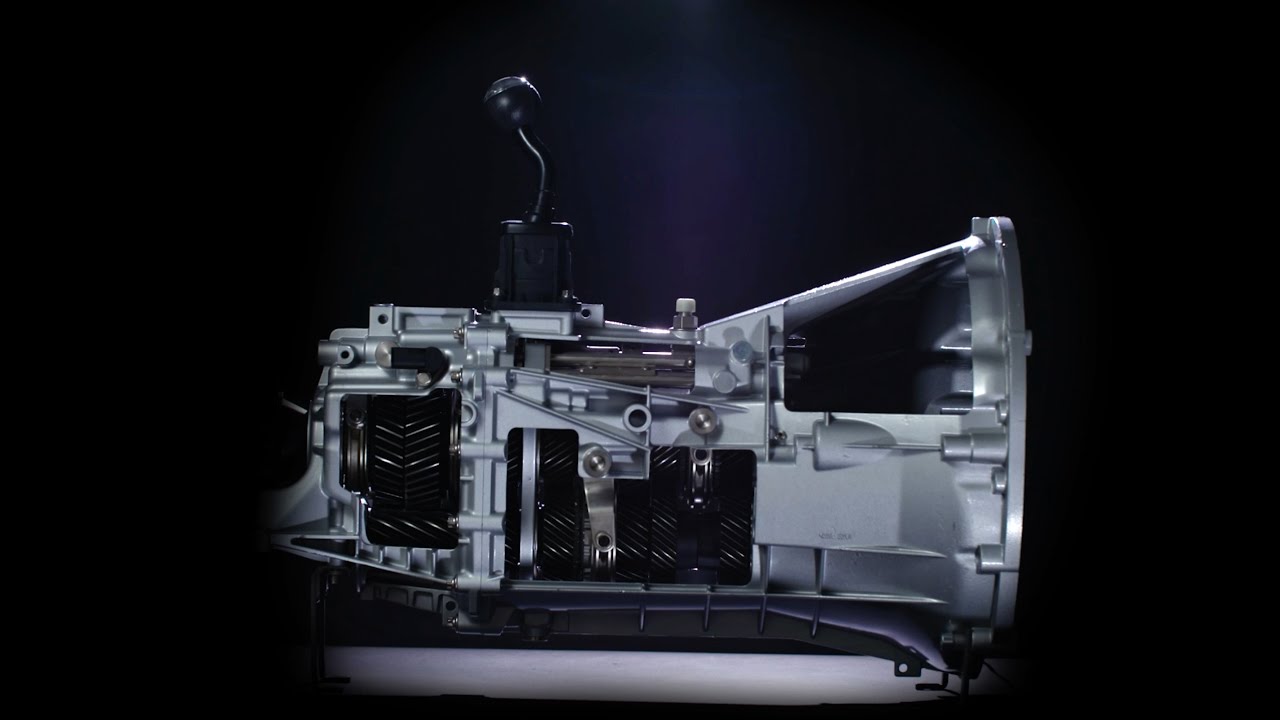

Custom Tooling, Workholding Help Whip Rotors Into Shape

Whipple Superchargers uses unique form tools and dead-length-collet workholding for its B-axis turn-mill enabling it to create more accurate rotors for its brand of engine power-adders.

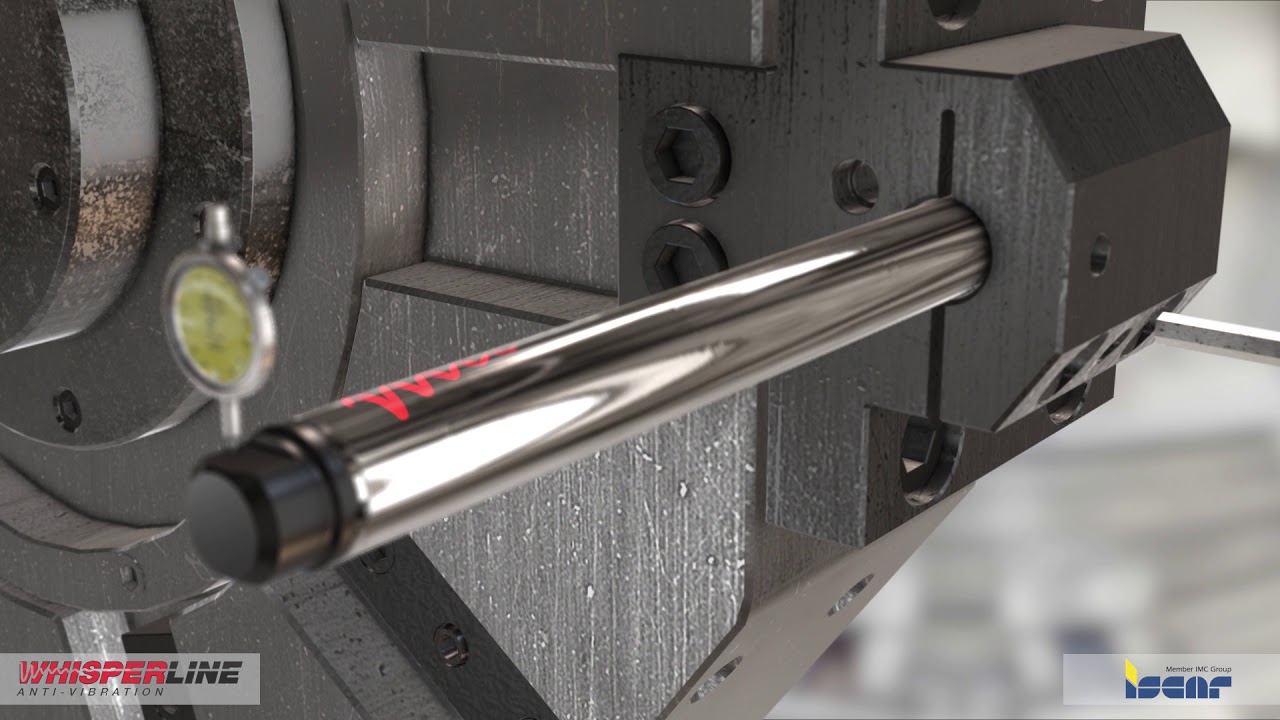

Faster Centerline Setups for Anti-Vibration Boring Bars

A serrated, magnetic device has been developed to speed centerline adjustment for Iscar’s Whisperline vibration-damping boring bars.

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

#basics

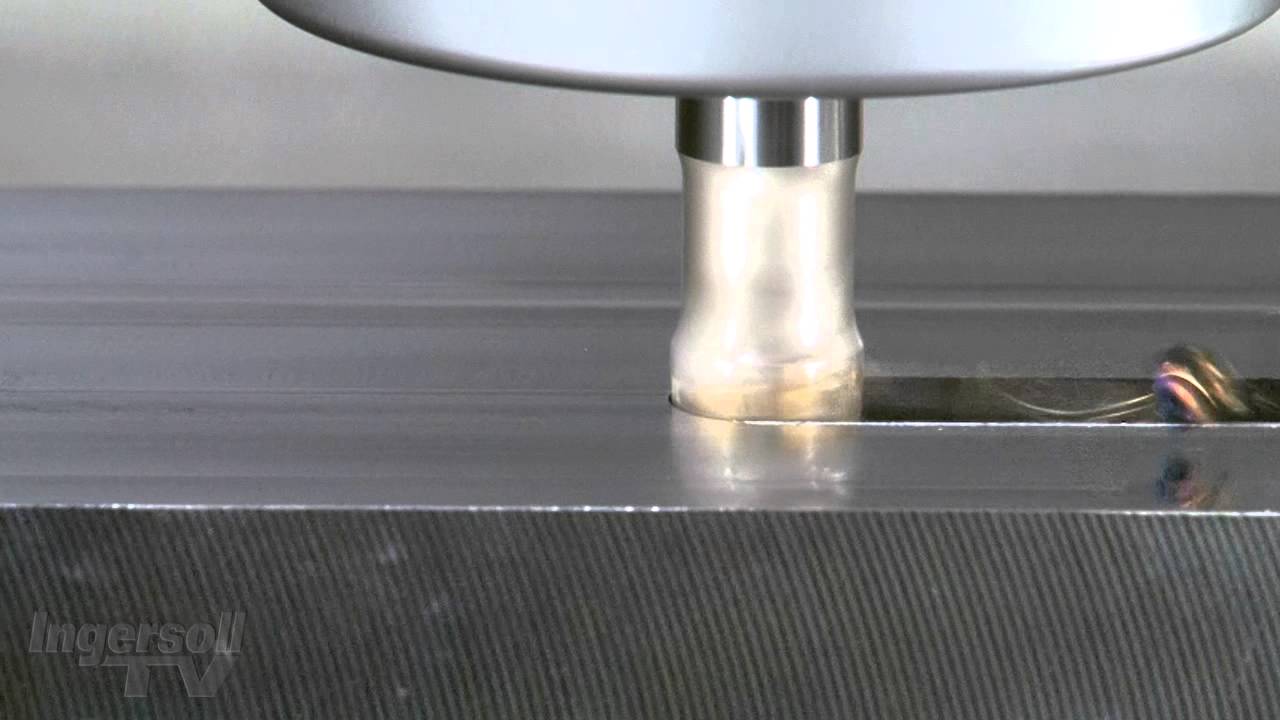

Video: High-Performance Hard Turning

Machine shops involved in turning hard parts will be interested in learning about these new inserts that were specially designed for this particular operation.

Video: Micro Insert for Live Tooling on Swiss Lathes

This easy-loading 5-mm I.C. micro insert is designed to run at maximum feed rates and is equipped with fine-pitched densities for high-productivity machining.