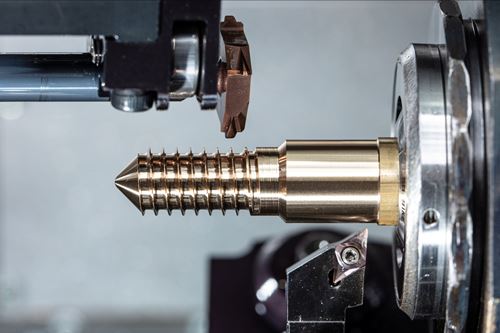

German Project Yields Three New Medical Machining Processes

Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

#techbrief

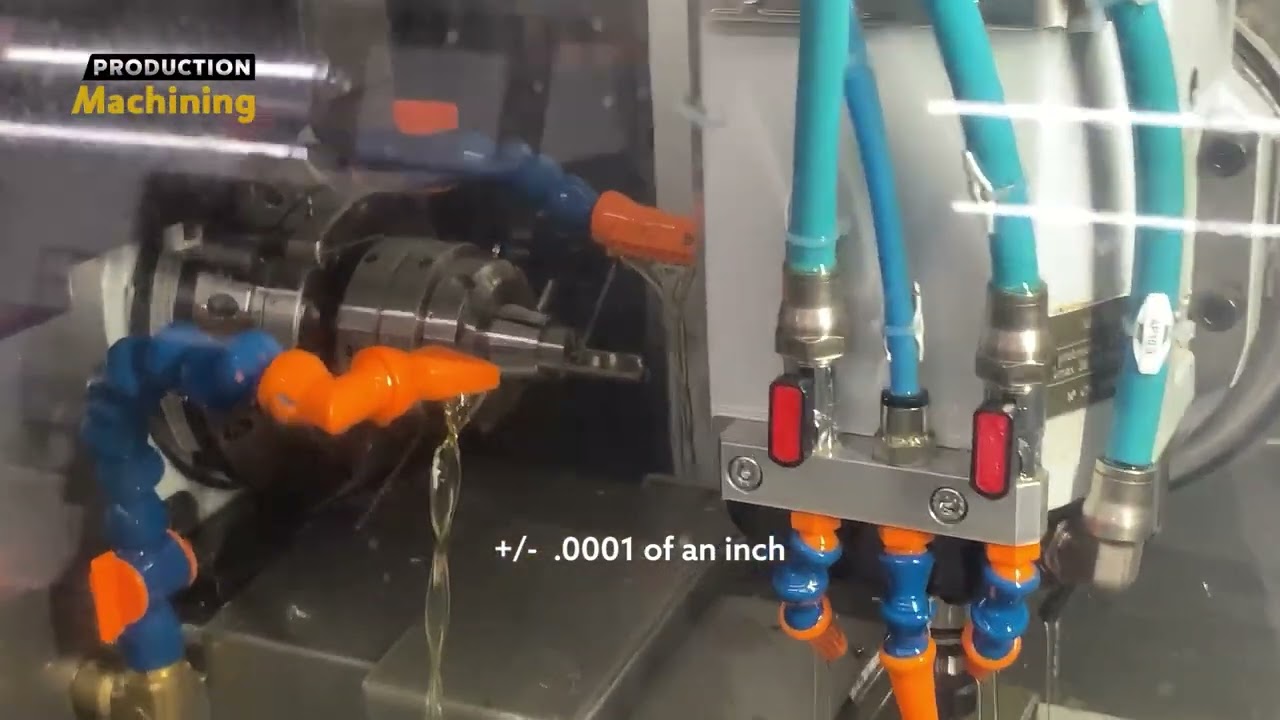

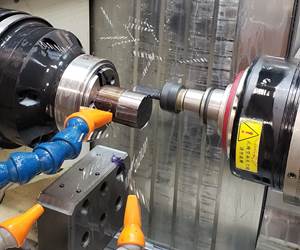

Five-Axis Machining for Small Prismatic Parts

New to the U.S. market, this compact machine could enable precision turning shops to win complex, more prismatic work in medical and other industries.

#techbrief

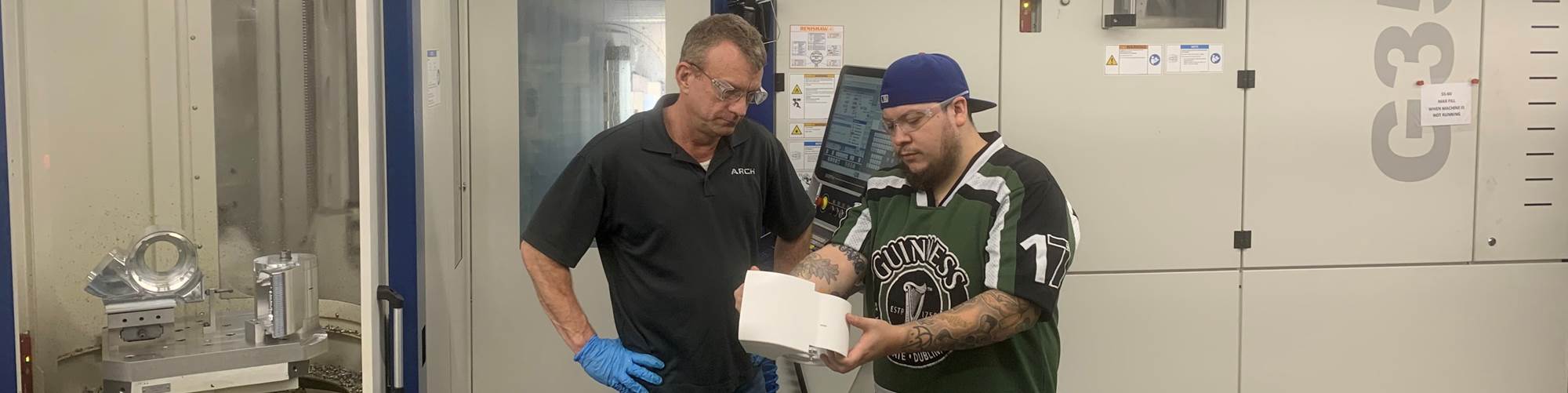

5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth.

How Small Machine Shops Can Fight Supply Chain Problems

Supply chain disruptions are still presenting challenges in manufacturing. This article examines the effects on aerospace, automotive and medical industries. It also covers ways that machine shops can be successful securing work despite the challenges created by the supply chain.

#columns