The second B-axis turn-mill MoManTech purchased currently performs no turning work whatsoever, producing a range of complex, prismatic medical components from barstock. (All photos are courtesy of MoManTech.)

I’ve visited a number of very advanced machining businesses that are located in the middle of nowhere. Due to coronavirus travel restrictions, I didn’t get to visit MoManTech — the precision machine shop profiled in this story — located in Sheridan, Montana. But, “middle of nowhere” is precisely how owner Kirt Johnston describes his business’ locale.

It took a leap of faith for him and his family to get there. Originally from Indiana, he had progressed up the management ranks at a medical device manufacturer in Warsaw. In 2003, at age 31, he was putting plans in place to purchase the company. His plans changed once he landed in the hospital as a result of work-related stress.

Featured Content

Kirt Johnston pulled up stakes in Indiana to move his family to Montana, where he purchased a small machine shop. He promptly added 4,000 square feet of floor space to the building as well as a diverse array of more advanced CNC equipment.

By chance, he learned about a small machine shop in a 700-person Montana town up for sale by an owner who had his own health issues and was eyeing retirement. That 1,800-square-foot shop had just a couple knee mills and three engine lathes. But it sat on three acres of land with killer views. Long story short, he bought that shop and moved his family there, leaving behind the security of existing employment for the unknowns this new experience would present.

And when I say he moved his family there, he did indeed. For a couple years, his wife and business partner, Michelle, and two boys — ages 2 and 5 at the time — lived in an 800-square-foot apartment attached to the shop.

The situation is much different now. After moving there in July 2004, Johnston expanded the shop by 4,000 square feet and began adding employees and more advanced CNC equipment, such as mills, a turning center, Swiss-type lathes, a wire EDM unit and B-axis turn-mills.

I’ve never installed a turning tool in it. — Kirt Johnston

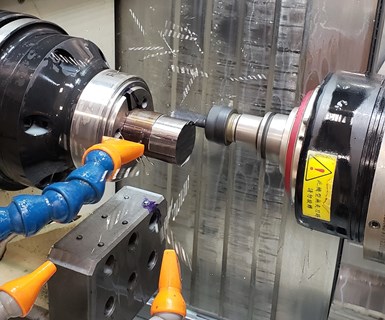

MoManTech’s first B-axis turn-mill, purchased in 2012, enabled the shop to go after more complex medical work. Its second one did as well. The latter is a QuickTech 9-axis S42ATM turn-mill machine with subspindle from Absolute Machine Tools, which was installed last July. Perhaps what is most interesting about this machine, which can perform both turning and milling work, is that it is used solely for milling. “I’ve never installed a turning tool in it,” Johnston says. Using this machine in this way has enabled the shop to perform faster changeovers for the 100 different part numbers in two part families that run across the machine, while leaving the option open for additional prismatic work machined from barstock, should that work present itself.

No Turning Back

ISO 13485-certified, MoManTech specializes in surgical devices for spine, trauma, large joint and dental applications as well as implants. Its range of capabilities enable it to be a virtual one-stop shop for its medical customers’ needs. In addition to its diverse machining capabilities, the shop has in-house secondary processes such as laser etching/marking, ultrasonic cleaning and citric passivation. MoManTech also has plastic and metal 3D printers it uses primarily to create fixtures used in the shop (see the sidebar below).

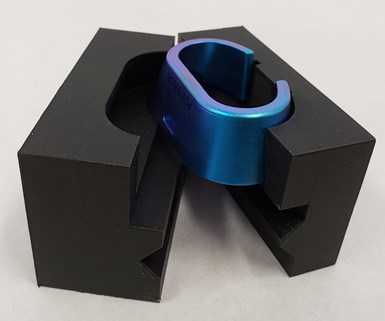

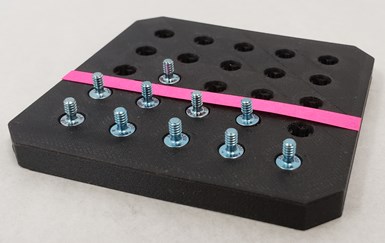

MoManTech machines a range of components for medical devices and implants.

The QuickTech S42ATM was its most recent capital equipment purchase. Johnston cites price and compact size as big reasons for choosing this model. But, he also appreciates that it has a full C-axis subspindle rather than a workpiece clamping device for backworking. The three-axis subspindle movement also contributes to the machine’s small size, as it can move in the X-axis above and below the part center line to provide the B-axis milling spindle with better access to the part. The B-axis has a 10,000-rpm, 3-hp motor and working range of 190° (±95° from vertical).

The machine has a 30-mm bar capacity. Rather than using a bar feeder, a bar puller is used to bring stock sawn in three-feet lengths into the work zone. This further reduces the amount of floor space the machine requires.

Rather than having a part clamping device for backworking, this turn-mill features a full C-axis subspindle.

Both the main spindle and subspindle have 6,000-rpm, 5-hp direct-drive motors. They are synchronized to enable accurate part transfer for backworking operations. The automatic tool changer (ATC) has 24 stations to accept HSK-40T toolholders.

MoManTech currently runs two part families across this machine. One is a family of titanium implants and the other is for stainless steel medical devices. All parts require five-axis machining (positioning, not full contouring) as well as backworking. Typical batch sizes range from 5 to 25. Producing prismatic parts from cylindrical barstock makes setups easier, compared to a conventional mill that might require special fixturing.

To minimize floor space, this B-axis turn-mill does not have a bar feeder. Instead, barstock is sawn in 3-foot lengths and pulled into the workzone.

Johnston takes advantage of the ATC’s capacity to keep many standard tools used for most jobs installed. That way, no touch-off is needed for those commonly used tools, thereby reducing changeover time to a new job. Changeovers typically require only a touch-off at the end of the barstock to set the work location and any new tools added for the new job. Absolute Machine Tools also created custom macros to carry over work offsets from the main spindle to the subspindle. That way, a tool touch-off is only needed on the main spindle.

Custom macros enable work offsets from the main spindle to be applied to the subspindle. Therefore, tool touch-off is only needed on the main spindle.

Effective machining of prismatic parts from barstock does require thought as to how a blocky part will be “oriented” within the volume of cylindrical barstock. Johnston tries to perform the bulk of the machining on the spindle side, leaving behind a feature that is easy for the subspindle to grip for backworking. This might only require machining of pockets in the subspindle jaws, instead of custom grippers. Most parts are machined complete and parts are ejected from the supspindle into a collection device.

More Work on the (Big Sky) Horizon?

When I spoke to Johnston in early May, he said his business had not been negatively impacted by the COVID-19 pandemic. Oddly enough, it actually offered an opportunity to add staff. He has hired people — one full-time and two part-time from college — who lost their summer jobs. Plus, as elective surgeries resume, it is possible the shop can see more work related to those procedures. This could lead to additional machine purchases down the road. And, who knows, maybe that new turn-mill will actually run jobs that require turning.

RELATED CONTENT

-

7 Causes of Quench Cracking in Steel

Failures of steel parts in service or production occur infrequently. However, when steel parts fail, the consequences are dire. Here are seven ways that steel can fail as a result of quench cracking from heat treatment.

-

Important Machining Factors of Carbon Steels

Learn the factors that contribute to carbon steels and their machinability as well as the 1214 steels, 1215 steels and 1018 steels, other grades, and more.

-

Predicting Size Change from Heat Treatment

While a precise forecast of a steel part’s size change during heat treating cannot be expected, by considering potential factors, a heat treater can provide a reasonable estimate that can help the shop prepare for final machining operations.