Digital data management is increasingly driving manufacturing strategy, operations, and asset allocation in contemporary manufacturing companies, however, collecting and comparing machining data in a uniform way can be a challenge for shops with a mix of new technology and legacy equipment. Dan Villemaire is owner and president of C&M Machine Products. Founded by his grandfather and father as a Brown & Sharpe screw machine shop in Hudson, New Hampshire, 40 years ago, the business has grown to house about 100 machines including more than 73 CNC Swiss-type lathes and 19 larger CNC turning centers. C&M serves industries ranging from aerospace and defense to copper consumables, fluid handling, medical, robotics and optics with production runs of precision machined products up to 1,000,000 pieces or more.

Mr. Villemaire perceived that detailed manufacturing data management and analysis would help facilitate growth into new markets through more efficient scheduling and use of manufacturing resources. “One of the things that we consistently strive to do is drive decisions with data,” he says. But because the shop’s machines are of widely differing age and operation, it was difficult to collect accurate, consistent and comparable data. “We wanted to have a better understanding of what our machines were doing. We knew that some of our machines had the capability to talk to us and give us information in a dashboard type of format, but not in a uniform way.”

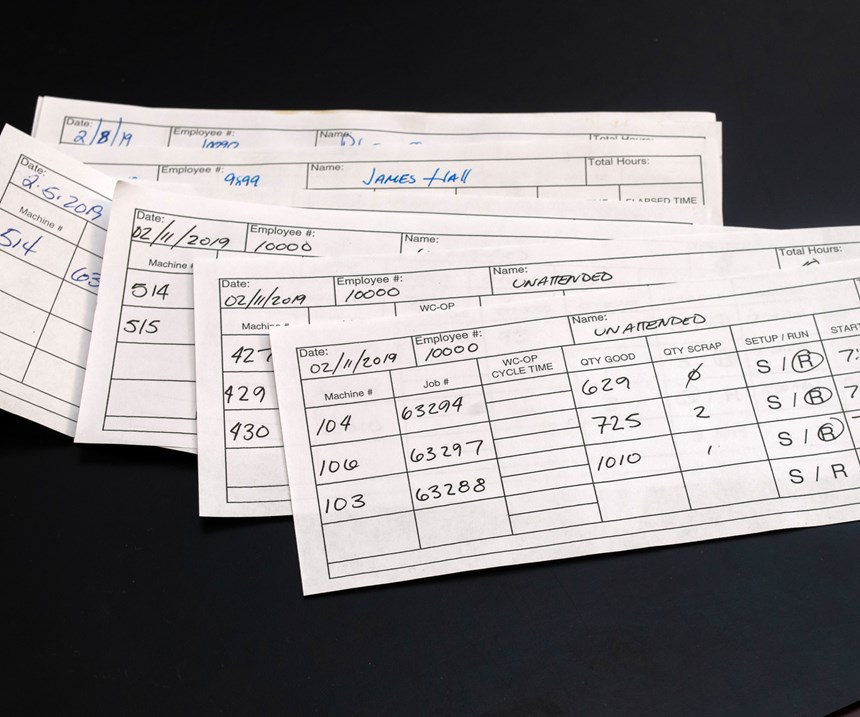

C&M sends CNC programs to its machines via a DNC (distributed numerical control) system, but the shop traditionally documented machine output using time cards filled out by hand. Operators manually recorded the hours they worked and the parts they produced, and then submitted the cards for entry into the shop’s ERP system. That process did not work well with multiple opportunities for error.

C&M acquired its DNC system from WireFreeCNC, a unit of Macdac Engineering. Macdac provides manufacturing software and hardware products including Mastercam, Catia and a variety of networking equipment. The software provider proposed installing the Excellerant MDC (Manufacturing Data Collection) at C&M. Excellerant is a universal decoder that connects machines and captures CNC data as it is generated. The product enables a manufacturer to connect all of its CNC machine tools and controllers (regardless of brand) and monitor and manage each machine’s data in real time and transmit that data to the company’s ERP system.

DNC Advantages

Excellerant MDC builds on MTConnect, FANUC Focas, OPC-UA, Haas MNET Q-Codes and other machine control connecting protocols, and it also communicates with legacy CNC machines. The package consists of a software license and hardware that includes a graphic display tablet located at each machine controller. The system counts parts as they are created. At the end of each shift, the operator qualifies the number of good parts completed, and the total is automatically entered into the ERP system.

With accurate data, the shop is able to better understand its true yield. “We didn’t really have good figures to be able to look at those things before,” Mr. Villemaire says. “This system is allowing us to do that. It’s very helpful. We’re not relying on handwritten time cards, and we’re not relying on our operators to drive C&M’s yield and throughput calculations.”

Shawn Bergeron, C&M’s continuous improvement leader, says, “The accuracy of information that’s coming into our ERP system is exponentially better than what it was before. From a scheduling perspective, it’s improving a lot of things.”

The incorrect output numbers common in the past, Mr. Bergeron stresses, were not the result of deception by machine operators. “They simply didn’t know,” he says. “We had occasions where parts just went missing. For instance, we ran 1,000 parts, but the operator had 700 in hand, so he thought he made 700. Actually, the missing 300 parts weren’t being caught properly in the machine, and they fell into the chip bin.”

Such occurrences affected profitability. “Our yield is impacted when parts are lost in the machine. We’ve spent cycle time, and we’ve consumed material and labor to make something that we can’t turn around and sell to a customer. It’s scrap regardless if it’s in the machine or not, and it needs to be accounted for that way. Now, through reliable data collection and root cause analysis, we know the issues we need to correct,” Mr. Bergeron says.

The most visible benefit of implementing the Excellerant package was elimination of time cards. C&M is also piloting removing additional documentation—count sheets that keep track of daily part counts through multiple shifts. The system does this automatically, giving operators an idea of where they are relative to the make quantity for the job, preventing overruns. The information also can confirm that the amount of material on hand is sufficient to complete the required part volume. “Automatic documentation saves 15 or 20 minutes for the operators that they can repurpose for getting the machines cleaned up and ready for the next shift,” Mr. Villemaire says.

The goal is to automate data collection as much as possible. Then management can start to analyze the data and find ways to deal with yield issues. “Use of the system also adds value from a customer satisfaction point of view, as we are able to improve accuracy of our costs and increase our value to our customers,” Mr. Bergeron says.

Changing Culture

Wholesale adoption of automated data collection represents a significant cultural shift for a 40-year-old business. Mr. Villemaire is moving C&M away from the older ways of doing things by surrounding himself with fresh resources and ideas. Mr Bergeron explains, “We recently hired an operations manager and a quality manager with a different skill set than what we’ve had previously. We hired a finance manager as well. Dan is trying to surround himself with a core team to bring this organization to where it needs to go based on facts and data, not based on emotion and a ‘we did it this way 30 years ago’ attitude. If we continue to do it that way, 30 years from now we won’t have a place to go.” The company is looking to hire 55 people over the next three to four years.

Better Buy-In

Employees, and operators in particular, have bought into the implementation of the Excellerant system more openly than what Mr. Bergeron anticipated. “I’ve had operators notice that we’re keeping better track of the information,” he says. “They’re seeing the value. It’s not a tool to reprimand people. That’s the very last thing we want to do. We’d rather use it as a tool for root-cause analysis and corrective and preventive actions going forward. The future benefits are tremendous.”

Paperless Environment

One of the objectives of adopting automated data management is to move toward a paperless environment, especially on the shop floor. A key element of that effort is a graphic display tablet mounted on each machine tool. On the tablet, which displays a simple user interface designed for clear and logical function, machine tools are represented by graphic icons.

A machine usually is idle when an operator signs in. After the operator enters an employee number, the machine’s icon turns red, indicating it is in the setup mode. When setup is complete, the icon changes from red to orange. After the operator finishes setup, including submitting nominal dimensions for the first piece, the system establishes a part count. When the first piece is confirmed to be a good part, the operator qualifies that piece into production and begins the production run. During the run the operator can log in and check the machine output compared with the production schedule and required part total. At the end of the run, the operator tells the system how many good parts were made. The graphic tablet display is also available on desktop computers in the shop office as well as on mobile devices.

Paperwork reduction also contributes to regulatory compliance. For example, Mr. Bergeron says use of the Excellerant system facilitates compliance with NIST (National Institute of Standards and Technology) standards, particularly cyber-security standard SP800-171. Large fines are possible in the event of a data breach. “That requires us to be very careful with our customer intellectual property such as specifications and drawings,” he says. “In many cases it is part of our contractual obligation to customers to control their information and guarantee it doesn’t fall into the wrong hands.” Storing information on the tablet on the machine limits the number of customer prints and specifications present on the shop floor. “In some cases, the cyber-security standard is sort of a barrier to entry to a market for other shops,” Mr. Bergeron continues. “A lot of our customers, specifically in the defense realm, are asking us if and when we’ll be compliant.”

A Varied Mix of Machine Tools

C&M operates more than 73 Swiss-type CNC lathes including machines from Star, Citizen and Tsugami. Larger CNC turning centers include machines from Miyano, Eurotech and Hardinge. Machine controls are from FANUC and Mitsubishi. Mr. Bergeron says the number and variety of machines in the C&M shop posed a challenge in collecting and standardizing data. “Each one’s slightly different than the next, and we have a lot of older machines. On the newer machines, implementing Excellerant is pretty quick and easy; it’s kind of plug and play. There was a lot more interaction with the older machines to get the system set up. But now it’s on just about every machine we have, and we have six new Citizen CNC Swiss lathes that we’re adding it to.”

The shop manufactures parts ranging in diameter from 0.03125 inch to 1.5 inches on its Swiss automatic lathes and up to 4 inches in diameter on the larger turning centers. “So, there is quite a big difference in the size of work that we can do along with different machine capabilities. We can look at what our different machines are capable of and schedule accordingly,” Mr. Bergeron says. The company has done a lot of work figuring out the best machine platform for each job, and the Excellerant system is helping them to better understand these choices.

Mr. Bergeron says input on use of the system comes largely from the shop floor. “It doesn’t come from me or anybody in management; it comes from the employees using the system every day. And that’s where the success is going to lie—in the employees adopting it and seeing the benefit of the system,” he explains. Some of them can dig in and do a root-cause analysis for part count issues. For others, once it’s up and running it just works, as long as people are following directions. “It is essential that employees trust the system. All that is required is fine tuning and paying attention to detail. Our machinists are extremely detail-oriented and produce very small parts with extremely fine tolerances. I know they can do this.”

Important Features

Mr. Bergeron notes that an important feature of the system is called the Eagle Eye View, which provides complete job detail such as customer information, part number, print number, revisions, job status, when parts were ordered, due dates, and updated order quantities.

Operation Notes is another valuable feature, enabling two-way communication between the office and the floor. Either the operator or office personnel can type a message that will appear on the tablet at the machine as well as on dashboards behind the scenes. “It could be something as simple as how well the job ran the night before and if there were any issues, sharing information with the upcoming shift,” Mr. Bergeron says. The shop runs a first shift and a modified second shift; there may be a three- or four-hour gap between shift handoff from night to morning. “With Macdac, we are developing the ability to save the Operation Notes with the part number so the next time the job is scheduled, the operators or other employees can query the notes and know how the job ran previously.”

Value of Accessible Data

Reliable, accessible data highlights issues and brings them to the forefront. “If it’s not in front of you and you don’t pay attention and don’t try to do something about it, you’ll never get better,” Mr. Bergeron says. “Now that we have good data coming in, we can query yield data and analyze it for trends or patterns, or to see if there’s a certain machine that’s always a problem. With accurate data, there are a lot of different factors that we can understand and use to better operate our facility. The big transition now is for the middle management team to start utilizing the system to make decisions.”

The data enables jobs to be scheduled on the correct platforms. C&M had incidents in the past where a job was scheduled on a machine that wasn’t available. The Excellerant system shows where each job is going and gives insight into what’s going on at the moment. It can be used to direct traffic and make decisions.

Adopting Automated Data Management Technology

Shops considering employing automated data management technology will find it helpful to make their processes as consistent as possible across the board. As an example, criteria for part counts should be standardized if possible. Considering the nature of C&M’s parts and machine tools, part counts in general are based on cutoff operations. When parts are turned from

bar-fed stock, cutoff signifies that a part is complete. In that case, it is actually an operation count rather than an actual part count. “It’s not necessarily cut and dry as to what is going to give you part counts,” Mr. Bergeron says. “You just have to make sure there are certain codes or variables in the machining programs, and you need to have somebody on the team who understands the code—in this case the programmer. Standardizing as much as possible makes it easier to troubleshoot as well.”

In preparing for the change to automated data collection, naming a project leader or champion is crucial in assuring that the effort stays on track and that there is a clearly defined point person for communications on any delays or other occurrences. Good rapport with the supplier of the data management system is essential.

Mr. Bergeron emphasizes the need to assemble a multidisciplinary team even prior to signing a data management contract. “The team should consist of representatives from operations, IT, and a champion from the shop floor, but it really involves a lot of people from all different disciplines in the shop,” he says. “The key is to get an idea beforehand of how the system will work. Those discussions can start, and the seeds can be planted, so when the system is implemented, it’s not all brand new. It requires everybody in the organization to participate to a certain degree.”

The Future of Automated Data Collection

Mr. Bergeron says, “Excellerant can be used in every operation in the manufacturing process, but currently we don’t apply the system to its full capacity. We use it on setup and production on the machine tools, and not yet in final inspection, shipping, or other aspects of the process. In the future we’ll be further leveraging the technology and taking maximum advantage of it. The whole point is to gather data and feed it back into the system for our employees to use. They know better than anybody else what’s going on.”

C&M Machine Products | 603-889-1330 | cm-machineproducts.com

Macdac Engineering Inc. | 860-749-5544 | macdac.comRELATED CONTENT

-

A Fitting Machining Process

Diversified Fittings has turned to twin-turret/twin-spindle equipment and machine monitoring to become more efficient producing hydraulic fittings and adaptors.

-

Determine Equipment Effectiveness

Keeping the "green" lights on is the goal of overall equipment effectiveness (OEE).

-

Automatically Optimize Your CNC Machining Feed Rates

New feed-rate-optimization technology can enable CAM programmers to reduce cycle times and increase tool life for milling and turning operations.