Is a ‘Side Hustle’ on Your Horizon?

By: Derek Korn

I’ve written about machine shops that have created a separate business for fun, as a complement to their existing operation or as a means to leverage their manufacturing prowess. Here’s a bit about a few of them.

#columns

The Value of CMM Controller Retrofits

Edited by Derek Korn

In this case, new controllers for two coordinate measuring machines — one 26 years old — with new programming software offers the possibility to enable multisensor inspection of critical, turned aerospace components.

#techbrief

Job Shop Discovers and Fills a Fishing Need

Edited by Derek Korn

The promise of a product line for improved mounting of electronic fish finders led this Missouri job shop to an automated turning process.

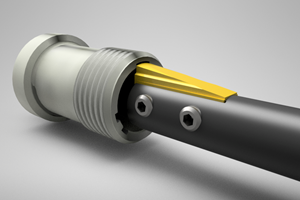

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

Edited by Derek Korn

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

How Well do You Know Granite Surface Plates?

Edited by Derek Korn

Here are some tips for choosing, maintaining and customizing a granite solution that will best meet your shop’s particular inspection needs.

A Tale About an Automation Solution Discovered in Production Machining

By: Derek Korn

A CNC Swiss production supervisor took to LinkedIn to describe how he discovered a rotary parts collector in the pages of our publication and has since purchased and benefited from it.

#columns

Consider This Another CMMC Reminder

By: Derek Korn

Machine shops serving the military/defense industry that currently aren’t working toward achieving Cybersecurity Maturity Model Certification could be caught flat-footed once it’s required.

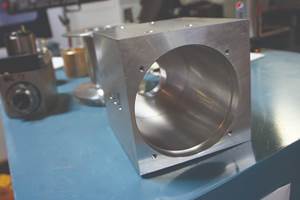

When a “Boxy” Part is Machined on a Lathe

Edited by Derek Korn

South Morgan Technologies has long thrived on its ability to mill prismatic parts on a turning platform. Today, newer technology and techniques enable saying “yes” to that work than ever before.

#horizontal-and-vertical-lathes

The Value of RFID Machine Operator Authentication

Edited by Derek Korn

Can secure shopfloor employee authentication via radio frequency identification enable shops to optimize their data-driven manufacturing efforts?

#Industry40

Addressing Micro-Boring Challenges

By: Derek Korn

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

#techbrief #micromachining

Robotic Automation Options for Vertical Turning Centers

Edited by Derek Korn

Custom robotic machine tending systems designed for specific high-volume machining applications can yield significant productivity and product flow benefits.

#techbrief #horizontal-and-vertical-lathes

Parting Off: The Case for Standardizing on Sawing

By: Derek Korn

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

#techbrief