Artificial knee and hip joint replacements are now commonplace for patients across the world. Therefore, machining these medical implants continues to be not only a high-accuracy process but now requires even more efficiency for high-volume applications. Although implementing the latest CNC machining equipment is critical for these applications, the capabilities of the CNC that controls these machines producing these parts can be just as important.

Implantcast Corp. in Buxtehude, Germany, uses DMG MORI turn-mill machines equipped with Siemens CNC Sinumerik 840D sl to create its titanium hip implants in both high- and low-volume runs. Hans-Joachim Mahr, production manager at Implantcast, says the CNC assumes an important function for the transfer of the CAD/CAM data to the actual production. It brings the virtual model to life, he explains.

Featured Content

This Sinumerik CNC model is said to enable ease of programming for multi-axis turn-mill machines such as the DMG CTX Alpha 450TC. According to Implantcast, the CNC functionality provides important efficiencies such as fast machine setup with an easy, intuitive user interface. Among other items, it offers onboard measurement and permits five-axis simultaneous machining that significantly reduces processing time.

Simplifying Machine Setup

With over 250 employees, Implantcast produces prostheses for customers in 52 countries. It specializes in the production of primary prostheses, revision prostheses and tumor endoprostheses. The complete process — from product development, planning and production to sterile packaging — takes place at one facility.

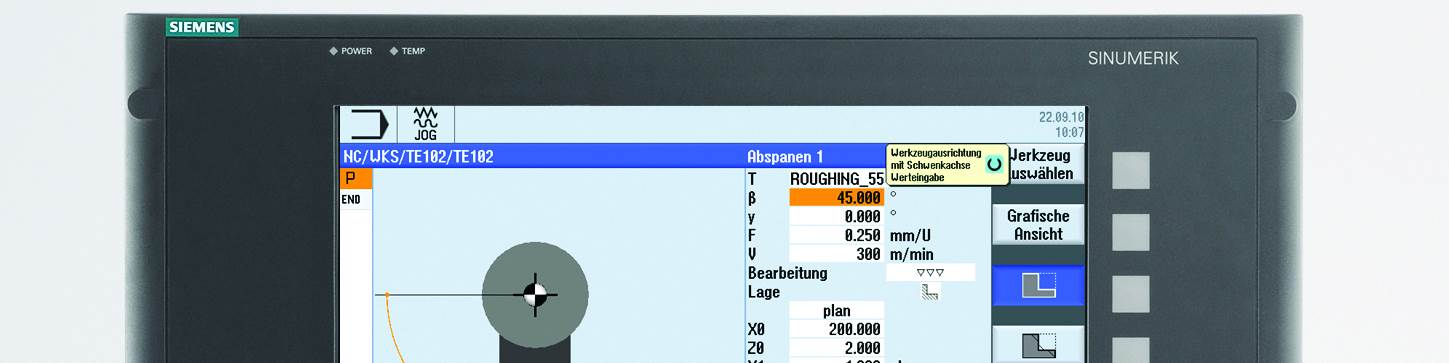

This Sinumerik 840D sl with the Sinumerik Operate user interface offers dual-channel representation in the CNC simulation that brings transparency to the programming and the setup, even for complex workpieces. Photo Credits: Siemens

The company produces complex single parts as well as high-production runs, and has therefore chosen CNC turn-mill machines that are suitable for both types of production. For particularly complicated applications, the company manufactures single-part, patient-specific implants. These specialty implants and instruments are cut perfectly to the associated bone structure with the help of a CT or MRI picture. Especially for these applications, the company uses the comprehensive setup functions of the Sinumerik 840D sl that permit fast machine setup.

For example, the Sinumerik Operate user interface integrates swivel commands that simplify machine setup. The Cycle 800 swivel cycle characterized by its easy handling and functions are available both for the swiveling in a machine axis and in an axis of the workpiece coordinate system. The CNC also handles any required coordinate transformation.

For high-volume production, the CNC permits five-axis simultaneous machining that significantly reduces the processing time.

Because standard implants have become available in various sizes, fast NC programming that defines the functions for machining the workpiece is critical. “Thanks to the user-friendly Sinumerik Operate, we save a significant amount of time,” says Axel Robiller, manager of the stock removal department at Implantcast. "One reason is that the human-machine interface (HMI) has the familiar Windows style known to us from the PC world."

Enabling Complete Machining in One Operation

The CNC turn-mill machines producing the implants have parallel machining on the main and counter spindles and can machine parts in one operation.

The Sinumerik CNC provides turn-mill functions that can be used in combination. The complete scope of all milling functions is available — from the cycle technology to simultaneous free surface machining.

Because all operator functions and cycles on the CNC are supported with animated elements, the operator intuitively knows how the function is to be used without needing to consult the instruction manual. Dynamic vector graphics can be used to explain the input values, such as the parameterization of complex cycles. These graphics reflect the input values with their proportional representation.

Programming Complex Parts

Each implant comes with a tailored set of instruments required for implantation. This includes a surgical rasp used to prepare the bone that Implantcast also machines. Bone rasps are complex workpieces; they contain a rasp body with many rasp teeth located on the contoured outer surfaces.

Bone rasps with the joint implants for proper preparation of the bone are supplied to orthopedics for surgeries.

Siemens CNCs offer dual-channel production of bone rasps on machines with two slides. This enables turn-mill machines to operate even more efficiently because the complete programming functionality is available in both channels. The CNC’s Programsync function synchronizes the machining channels, no matter if the programs have been programmed in DIN/ISO, standard cycles or Siemens ShopTurn software.

The increasing complexity of the turn-mill machines and programs also increase the risk of programming errors that, under some circumstances, can cause machine damage. To prevent such errors, the Sinumerik 840D sl offers a program simulation that shows the stock removal process in virtual 3D. In addition to the complete representation of the cutting actions, the expected machining time corresponding to the programmed technology values is also displayed prior to the production of a single workpiece.

Meeting Stringent Requirements

Many intelligent functions are available on the CNC that assist with the measuring of tools and workpieces. These capabilities can be used for the setup and process measurement of the overall quality assurance during machining.

The Sinumerik MDynamics technology package ensures the required surface quality at high machining speed even for difficult materials. The Advanced Surface motion control produces milling surface results that meet the stringent requirements placed on medical implants and instruments.

Each individual part machined at Implantcast is subjected to comprehensive quality control. Sensing probes check the accuracy of the contour and the peak-to-valley height, and scan the surface for even the smallest damage. To check the material structure, X-ray examinations are also made on some parts. Only when all these hurdles have been overcome are the implants passed on for sterile packaging and shipping at the company.

RELATED CONTENT

-

Medical Screw Solution Includes More than Cutting Tools

With companies producing so many medical screws, every second saved counts. A turnkey program can help manufacturers machine these parts as efficiently as possible.

-

Advancements in Thread Whirling Tooling Technology

Many understand the advantages of thread whirling on a CNC Swiss-type. However, new tooling technology for this thread-machining process can further improve cycle times and reduce cost per part.

-

German Project Yields Three New Medical Machining Processes

Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.