This 7,000-square-foot building offers four times the assembly space than what was allotted at Hirsh Precision’s Boulder, Colorado, headquarters. Mobile assembly stations on carts enable easy configuration into cells when necessary.

Hirsh Precision Products is a machining and manufacturing company started by Steve Hirsh more than 42 years ago when he traded his Fiat X19 for a knee mill. That knee mill still resides in the toolroom of its Boulder, Colorado, headquarters as I noticed during a recent visit. But, a lot has changed since then, and the company has grown quite a bit in terms of its overall size and the sophistication of technology and processes.

The medical industry is driving a good bit of this growth. The company began serving medical customers approximately 30 years ago, and, in 2020, completed the medical ISO 13485 certification on the heels of its ISO 9001:2015 certification that was completed just a few years prior to that. Work for this industry represents approximately two-thirds of the company sales, with the rest comprising work for aerospace, scientific and general industrial applications.

Featured Content

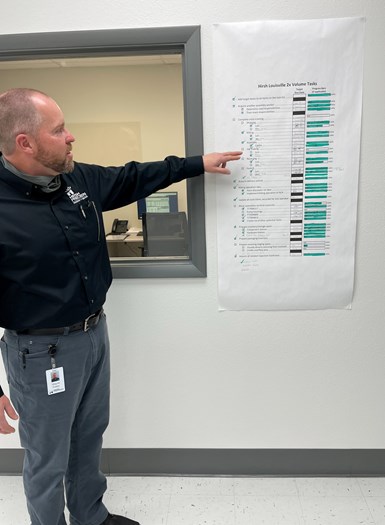

The company’s proprietary shop management system shown here being used at Hirsh Boulder is also used at Hirsh Louisville. This enables data to be shared and accessed easily at both locations on one platform. The software serves as an intuitive front-end interface with the company’s enterprise resource planning (ERP) system from Infor ERP.

When I say the manufacturer has grown a great bit, know that it recently found its 30,000-square-foot headquarters bursting at the seams with all of its CNC machining equipment, finishing processes (such as citric passivation), quality control and product assembly. And, there’s no available space to expand the building.

In an effort to support the company’s growth and expand its complex assembly services for medical and aerospace customers, Hirsh Precision Products decided to establish a separate facility that would be dedicated to assembly as well as inventory management. In September 2020, it moved most of those operations to a 7,000-square-foot building in nearby Louisville, Colorado. This new facility, dubbed Hirsh Louisville, offers four times the assembly floor space as well as improved lighting and a much more controlled environment to facilitate the type of precision work the four assembly employees perform there.

Wayne Fraley, general manager of Hirsh Louisville, says that location currently produces 27 different assemblies. However, he notes the goal is to double that number over the next couple of years in time for another big change for the company that’s on the horizon.

Moving assembly to a dedicated building freed some floor space for additional machining equipment at Hirsh Boulder. For example, the company recently added a third Okuma five-axis VMC to its high-production Fastems flexible manufacturing system (FMS).

Taking a “Full-Service” Approach

Fraley says calling the company a “machine shop” doesn’t best reflect what it is all about. “Our more ‘full-service’ approach enables us to handle customers’ mechanical and electro-mechanical assembly; source component parts through vendors and suppliers on the customers’ behalf; track the production, assembly and shipping of products using our proprietary shop floor management software; and manage the supply chain for manufactured and assembled products from beginning to end,” Fraley says.

Peter Doyle, president and CEO, adds that this goes beyond just providing assembly as a service. “Our engineering team is able to talk with a customer, not just about one specific part but how that parts fits in an assembly, what its purpose is, how the assembly functions and so on. This puts our team in a better position to consult with a customer’s engineers to offer manufacturability feedback while providing our team with a greater sense of ownership over all the processes that go into producing a final product,” Doyle says.

“Stringing” to finish orifice holes for parts such as these that require 40,000-psi flow, and some assembly of those parts, is still performed at Hirsh Boulder.

Hirsh Louisville is just a 20-minute drive from Hirsh Boulder within the Colorado Technology Center (CTC) industrial park. In fact, the building was perfectly suited for the clean assembly work to be performed there. The facility was previously used by a food processing company. It is well-lit and had multiple existing electrical and compressed air drops throughout. No real modifications were required outside of bringing in assembly equipment such as manual presses, hand tools and gages from Hirsh Boulder.

Hirsh Louisville offers 1,600 square-feet of assembly space. The rest is dedicated to inventory storage and packaging as well as offices for sales and marketing. Mobile benches are used for most assembly workstations as they can be easily maneuvered to create assembly cells for certain projects. Select assemblies might have as many as a few dozen different components. Some of those are machined at Hirsh Boulder and others, such as fasteners and springs, are sourced.

Close communication with Hirsh Boulder and its machining and inspection expertise facilitates the creation of fixtures for assembly presses as well as instruments such as this go/no-go gage. The shop can also laser mark devices such as this to tie it to a given product.

Approximately 50% of metal machined parts require anodizing, which is performed at a finishing company in Colorado Springs that Hirsh Precision Products had been partnering with and recently acquired. Final inspection of those parts is completed at Hirsh Boulder and then sent to Hirsh Louisville. There, those parts and sourced components are received, inspected (if they are sourced components), entered into the company’s proprietary shop floor management software (a common platform used at both company facilities) tracking them to a specific job and then put into inventory. Pick lists are then created and jobs are kitted on individual carts. Completed assemblies can then be packaged to prevent damage and shipped. These might be subassemblies or completed products for customers to sell.

Similarly, close communication between the two locations makes it easy to create fixtures for assembly presses as well as instruments such as go/no-go gages. Hirsh Boulder can also laser mark gages and other devices for identification per a given product.

Bringing it All Together

While the Hirsh Louisville building the company is leasing for its assembly and inventory management efforts was a necessary addition, it is a temporary solution. The company plans to move into a new 65,000-square-foot facility combining both the Boulder and Louisville operations under one roof.

Wayne Fraley, general manager of the Louisville facility, explains a checklist of training and operational goals, and ideas for this new assembly and inventory management location as it is part of the company’s culture of continuous improvement.

This new building is slated to be completed and operational in 2023. In the meantime, the company is determining an optimal layout to maximize flow, including where the assembly area will be located and how the current Hirsh Louisville operation will be replicated.

Fraley says the company would like to grow assembly to twice its current capacity of nearly 30 products by the time of the move. This gives the company time to fine-tune and expand its assembly business unit before the move.

Automated assembly processes are always considered, although Luis Gonzalez, assembly supervisor at Hirsh Louisville, says not all assembly processes lend themselves to automation. For example, he says some assemblies feature plastic components that require a bit of finesse and care when pressing in pins so as not to damage the part. Plus, the complexity of other assemblies would be a challenge to automate.

In any event, I’ve marked my calendar to revisit once the new building is up and running. I always enjoy comparing and contrasting innovative manufacturing companies in that way.

RELATED CONTENT

-

German Project Yields Three New Medical Machining Processes

Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

-

Medical Screw Solution Includes More than Cutting Tools

With companies producing so many medical screws, every second saved counts. A turnkey program can help manufacturers machine these parts as efficiently as possible.

-

Tooling Up for Micromachining

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.