Faster Centerline Setups for Anti-Vibration Boring Bars

A serrated, magnetic device has been developed to speed centerline adjustment for Iscar’s Whisperline vibration-damping boring bars.

Edited by Derek Korn

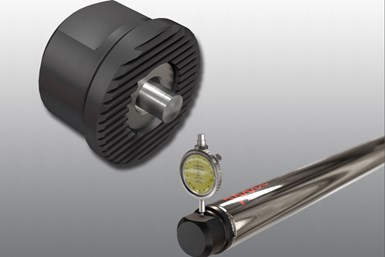

A magnetic device with a flat enables faster centerline adjustments of Iscar vibration-damping boring bars using a simple indicator. Photo Credit: Iscar

Technology to overcome the issues of vibration and chatter for long boring bars has been around for a while. Iscar’s Whisperline system, for example, features boring bars with an integral absorber to damp cutting tool vibrations to improve tool life and surface finish. The bars, onto which install exchangeable boring heads with cutters, are available in lengths ranging to 10xD.

Because these boring bars are made as cylindrical shanks without flats, it can be challenging to set a tool precisely to a CNC turning machine’s spindle centerline. However, the company has since developed a simple device to speed and simplify centerline adjustment, taking advantage of the serrated interface between the boring bar and exchangeable heads.

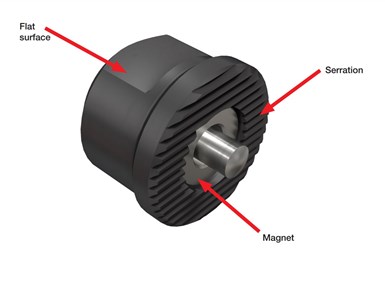

Here are the primary features of the device, which attaches to the end of a boring bar during centerline setup. Photo Credit: Iscar

The cylindrical device with serrations matching the end of the bar attaches to the bar via a magnet so no bolts are needed. It includes a flat feature that helps users rotate the bar so the tool on the exchangeable head is on the machine’s centerline once the head is installed. The bar is known to be rotated into proper position once an indicator run over the device’s flat feature shows no movement. The bar can then be clamped in place, the device removed and the proper exchangeable head bolted into place on the bar. This is shown in the video below.

The center height adjustment device is available in two sizes. The AVC-SET 16-25 fits 0.625-, 0.750- and 1.00-inch bar diameters and the AVC-SET 32-60 fits 1.25-, 1.50-, 2.00- and 2.50-inch bar diameters.

RELATED CONTENT

-

Calculating Surface Footage and RPM for Optimum Tool Life

Tech Brief: Calculating Surface Footage and RPM for Optimum Tool Life

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.