There can be a variety of reasons why a machine tool might be down or have performance issues. Some of these might be remedied via simple fixes, while others might not. Regardless, when a machine isn’t making chips, it isn’t making money. This can be exceedingly problematic for high-volume operations using equipment such as CNC multispindles that often are completing parts every few seconds.

Tajmac USA offers customers a means to use augmented reality (AR) to enable its service engineers to remotely diagnose potential issues with the machine tools it offers, including Mori-Say and Wickman multispindles, and possibly walk customers through fixes they can perform on their own. (Read on, then watch video demonstration below.)

Featured Content

Using augmented reality technology, Tajmac-USA service engineers can remotely troubleshoot machine tool issues and walk customers through a mechanical or electrical fix without being on-site. (Photo credits: PM)

“Rather than incurring the expense of an engineer to travel to your shop while your machine remains down as you await his or her arrival, our engineers can often walk your employees through basic and even more complex fixes remotely,” explains Jeremy Rose, CEO of Tajmac-USA. “Within an hour, we can be online seeing what your employee is seeing while making suggestions in real time. And in the process, we’re also training your personnel, so they are prepared to solve those issues on their own if such problems were to arise again.”

Petr Julina, the company’s operations manager, says the idea to use AR technology, which Tajmac-USA calls its ZARS system, came about during COVID-19 when many machine shops would not allow visitors, including outside service engineers, into their facilities. Customers having the ZARS system could enable Tajmac-USA’s service engineers to troubleshoot issues remotely so, in some cases, no on-site visit would be required, and a machine could get back online in short order.

Using the ZARS system, Tajmac-USA personnel such as Petr Julina is able to see exactly what the customer is seeing as he suggests ways to remedy a machine issue.

But the concept still applies today after most shops have now reopened their doors to visitors. Julina explains that the traditional method of troubleshooting even prior to a possible on-site visit could take time. This might have involved multiple phone calls, customers taking and emailing photos, and other means of communicating a machine’s issues pushing back the time a service engineer could travel if necessary.

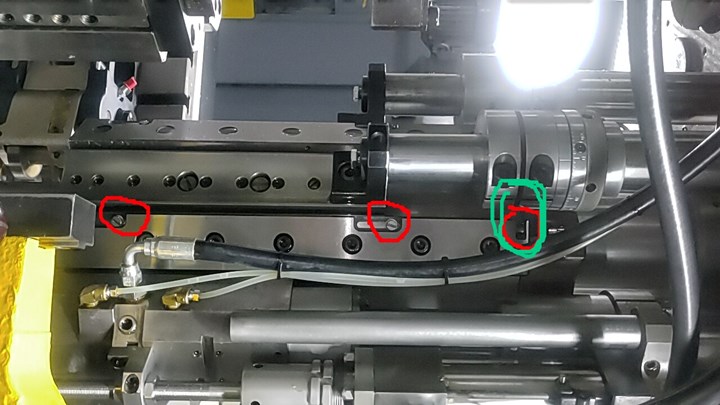

Remote service engineers can take screen captures of what the customer is viewing to highlight specific, critical areas of a machine to concentrate on during maintenance or repair.

The ZARS system can mitigate these issues. The kit a customer receives includes an AR camera with microphone and noise-canceling ear buds on a frame that attaches to a pair of safety glasses. (The frame can be removed and attached to a user’s prescription glasses if necessary.) The unit enables a remote Tajmac-USA service engineer to see precisely what the person at the shop wearing the unit sees, guiding him or her to look at what the service engineer would like to see on the machine. Being that it’s a hands-free device, the customer can work on the issue while receiving instructions from the service engineer.

Requisite software is pre-installed in the ZARS unit to enable communication with remote service engineers (both verbal and visual) and exchange of files such as maintenance instructions. The software also enables remote service engineers to take a photo and then circle or highlight critical areas of the machine for the customer to view. The only requirement on the shop’s end is providing Wi-Fi access for the ZARS system.

Julina says a problem could be as simple as tightening a loose wire in a machine’s electrical cabinet. But it could be more complex. As an example, the Tajmac-USA team recently walked a customer through replacing multiple machine motors, which required mechanical guidance for installing the motors as well as CNC guidance in terms of setting up the proper motor parameters. The video below runs through a few similar hypothetical scenarios.

RELATED CONTENT

-

Selecting A VMC: Factors To Consider

A three-, four- or five-axis vertical machining center can run the gamut of capability and cost. Assessing your application requirements now and in the future can make for a much wiser machining center purchase.

-

Diamond Lapping and Lapping Plate Control

The word “diamond” brings the word “expensive” to mind. But when it comes to lapping with diamond superabrasives, start thinking “low”—as in lower slurry consumption, lower slurry cost per hour, lower sludge generation, lower cycle time, lower reject rates and fewer process steps.

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.