Reaming can offer an alternative to single-point boring to solve issues such as subpar chip control and long cycle times. (Photo credits: Monaghan Tooling)

Slip yokes, pivotal to drivetrains ranging from compact vehicles to heavy construction equipment, demand precise finish machining operations to function optimally. Specifically, these components, frequently cast from materials such as ductile iron, mild steel or stainless steel, require meticulous machining of a through hole that houses a bearing. However, single-point boring, a conventional method used for creating this hole, can sometimes result in complications including chip control issues, extended cycle times and short tool life.

Single-point boring, although capable, can directly impact production efficiency and part quality. An immediate concern is chip control. During the boring process, the lack of effective chip evacuation in some single-point boring tools leads to the accumulation of large, stringy chips, causing potential damage to the tool doing the finishing work of the bore. Chips that wrap around a tool can damage the part, causing it to be scrapped. Work stoppages to clear the accumulated chips can help to lower the scrap rate, but have a detrimental effect on production volume and efficiency.

Featured Content

In today’s automated manufacturing environment, chip buildup can interfere with automated parts loaders, triggering emergency stoppages and disrupting production efficiency. A need for constant supervision to clear these chips runs counter to the principle of automation and leads to unnecessary stoppage of the machine tool.

Slip yokes have a critical through hole housing a bearing that requires meticulous machining.

Also, with just a single cutting surface, single-point boring is inherently time-consuming and requires what can be a lengthy setup process which often demands the expertise of skilled operators. Parts can perhaps be scrapped while dialing in the tooling, too. As a result, single-point boring a component that should ideally be produced within minutes can instead take hours, resulting in high scrap rates due to improper bore size and increased machine downtime. The situation is further compounded when dealing with hard-to-machine materials in which tool life for a single-point boring insert is substantially shortened. So, although single-point boring can be effective in machining slip yokes, when considering cycle time, tool life and scrap rate, and how they negatively impact cost per piece, the process could be improved.

Multi-blade, high-performance reamers are designed to eliminate the issues often associated with single-point boring. Multi-blade reamers, such as those made by Diatool (available from Monaghan Tooling Group), distribute the cutting action over many cutting edges versus only a single effective cutting surface.

They also feature uneven spacing of cutting blades to achieve precise concentricity. The immediate advantages of using multi-blade reamers with uneven blade spacing are increased bore quality for size control, roundness of the bore, surface finish, decreased cycle time and elimination of any adjustment for size. This enables the machine operator to keep the machine running without stopping due to the enhanced process security.

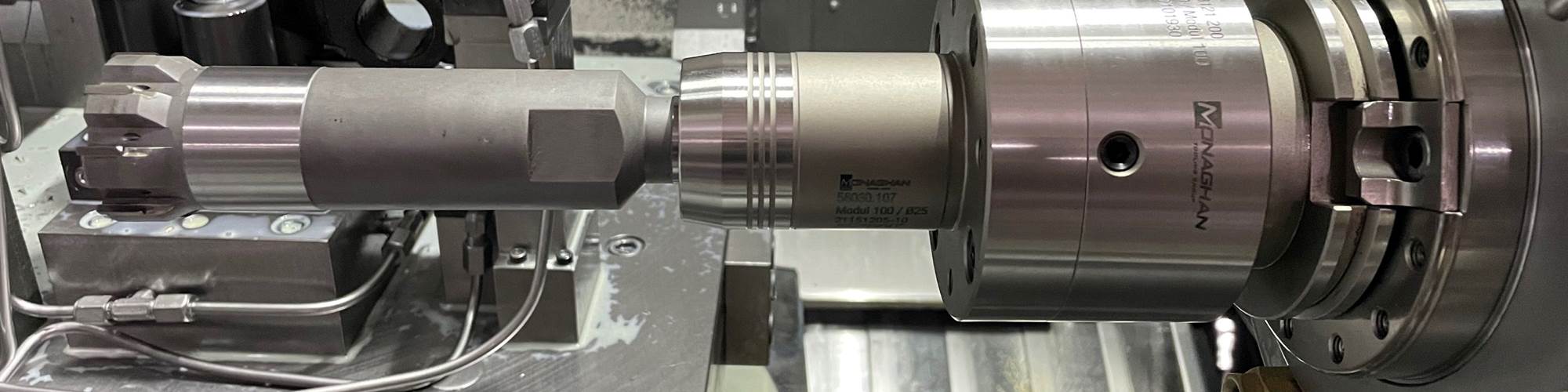

Multi-blade reamers with uneven blade spacing can offer precise bore roundness, size control and surface finish.

Designed with the part-specific application in mind, Diatool reamers offering high stability are delivered on size and ready to ready to cut — no size adjustment is required. The proprietary cutting geometry is said to ensure efficient chip evacuation, eliminating accumulation that can lead to tool and part damage, as well as machine stoppages.

This multi-blade reamer’s proprietary cutting geometry is said to ensure efficient chip evacuation eliminating accumulation that can lead to tool and part damage as well as machine stoppages.

With eight (or more) cermet blades, high-performance reamers can also outperform single-point boring tools, reducing machining time from minutes to seconds. The multi-blade design and cermet cutting blades enable high cutting speeds and increased feed rates, resulting in considerable machine time savings.

For example, saving just 30 seconds of machining time over a 250,000-piece run can translate to over 2,000 hours of machine time savings per year. At a machine rate of $85 per hour, the machine time savings can add up to over $175,000 annually. Reduced scrap rates can further enhances the savings.

To maintain bore size and account for blade wear, Diatool reamers also offer a micro-expansion feature to help continuously achieve tight tolerances while increasing tool life. Similarly, cermet-tipped blades combined with chipbreaking technology can offer high durability while also extending tool life. Reduced tool replacement directly translates to lower production costs, minimized machine downtime and lower cost per unit.

RELATED CONTENT

-

Video Tech Brief: Live-Tool, Y-Axis CNC Lathe with a Compact Footprint

This small footprint, big-bore lathe offers a generous work envelope. The addition of Y-axis and live tooling enables milling, drilling and tapping for increased machine capabilities.

-

5 Questions About Honing

Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Here, a leading honing equipment manufacturer answers a few commonly asked questions about this process.

-

Craftsman Cribsheet No. 119: Defeating the Hanging Cross-Hole Burr

Deburring is a tedious task that is better left to machines.