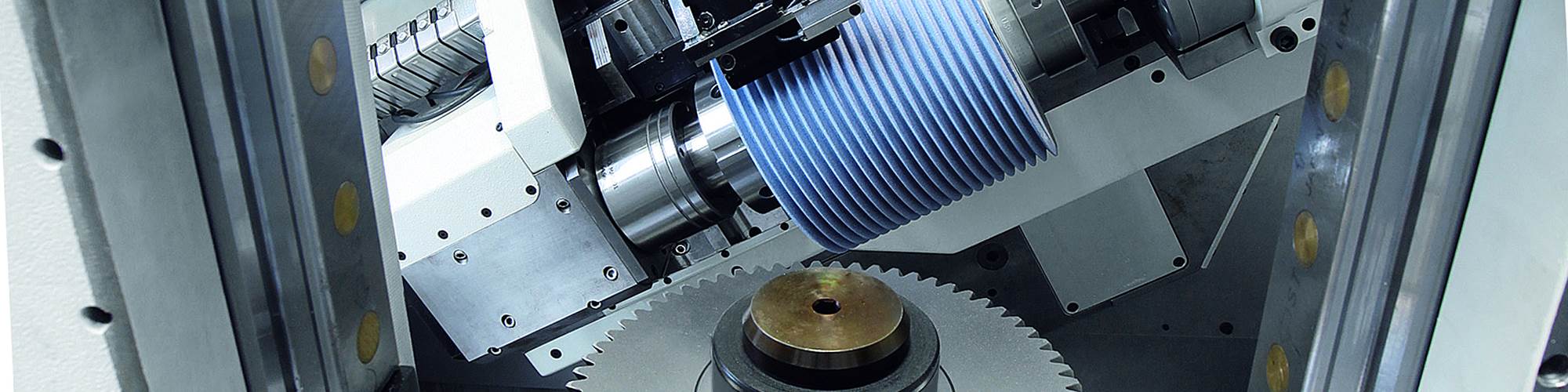

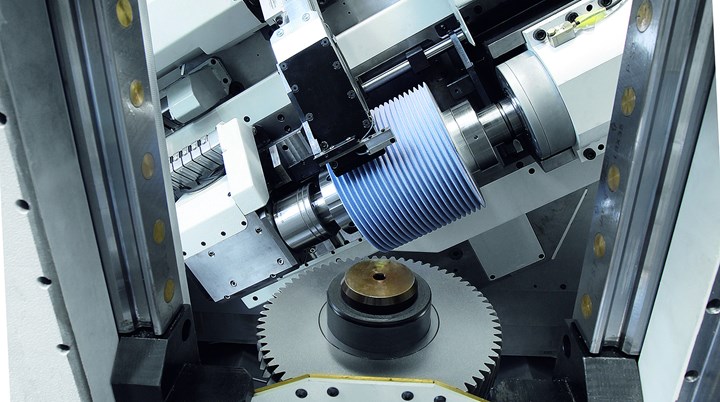

The G 160 gear generating grinding machine features simultaneous movement of all axes which results in a chip-to-chip time of less than 2 seconds. Due to its axis concept, the grinding head is very short, which has a favorable influence on reducing vibration behavior during grinding, the company says. (Photo Credits: Emag SU)

Most top automotive manufacturers launched new electric vehicle (EV) models in 2022. But what does this mean for the production planning by OEMs and suppliers?

“On the one hand, they have to effectively deal with growing production quantities, yet still have to guarantee an ever increasing level of quality, because the high torque load of an EV electric motor results in special requirements for tight tolerance dimensions and surface finish,” explains Alexander Morhard, technical gear support specialist with Emag SU. “This development is particularly noticeable in the machining of tooth flanks on shafts and gears. Here it is important to achieve dimensionally accurate results in the micron range, because even minimal ripple in the surface finishing of the components can cause interference noise in the drive performance.”

Featured Content

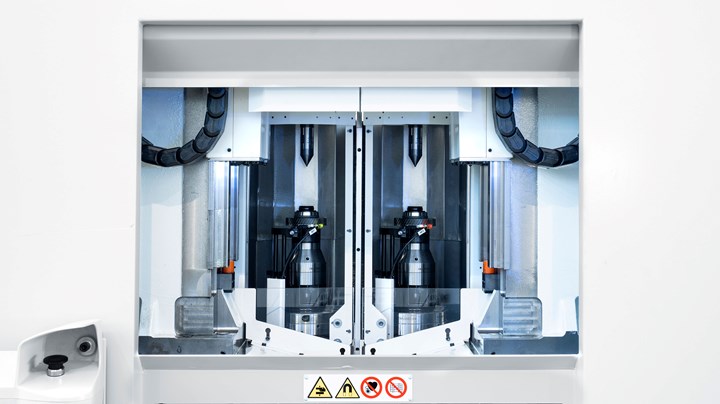

The G 160 has two parallel workpiece tables that move alternately at high speed to the grinding wheel. The integrated dressing unit is said to provide additional process reliability.

Emag SU offers a range of CNC machines that cover the entire gear tooth cutting process, including tooth flank grinding in which “generating grinding” and “profile grinding” are key areas of application.

With generating grinding, the gear geometry is continuously generated by a combination of multi-axis, high-performance machine motions and well-maintained grinding wheels, the company says. Its G 160 model, for example, offers high speed for components up to module 3 with a maximum outside diameter of 160 mm. The G 160’s speed is said to be made possible by a slide axis concept with two parallel workpiece tables that take turns moving at high speed (with the help of linear motors) to the grinding wheel. During the time that one component is being machined, a loading robot inserts a blank into the other spindle, after first unloading the completed part, as needed. Self-centering alignment or “meshing” of the grinding wheel to the rough-cut gear component takes place directly on the workpiece spindle, at load position, in parallel with the main machining operation. This results in a chip-to-chip time between the grinding processes of only 1.6 seconds, which the company says is a small value compared to grinding machines with turntables that might take as much as 5 seconds.

Emag SU says it is important to recognize that the actual grinding time needed for a typical component, such as a planetary gear wheel, is only about 10 seconds. Therefore, the difference between the chip-to-chip times between grinding becomes significant, especially for high-volume manufacturing scenarios.

The ability to achieve quality surface finishes is also key, the company explains. As opposed to some other gear-grinding machines, the G 160 has no tangential axis. Instead, the Y and Z axes “generate” a “virtual” tangential axis through simultaneous movement. Therefore, the point of contact between the grinding wheel and workpiece is approximately 100 mm closer to the pivot point of the swiveling axis, which is beneficial for the swiveling behavior during the grinding process. The wheel point of contact varies, smoothing the gear form for better meshing and higher bearing ratios. The result is visible in the surface structure of the finished component, as “ghost frequencies” in the micron range vanish almost entirely. Additionally, gear form profile deviation is very low, as measured by the force field approximation (FFA) value.

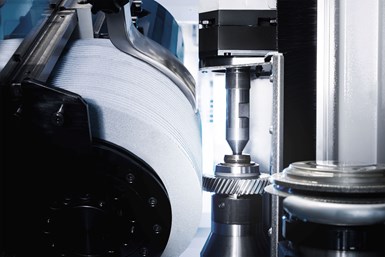

Emag SU says its G 250 machine offers another alternative suitable for components up to module 7 with an outside diameter of 250 mm. Axle drive gears, gear wheels or shafts with a maximum length of 550 mm can be produced using generating grinding or profile grinding processes. The machine is equipped with two table spindles to minimize idle time during the manufacturing process. “Additionally, the flexibility of the machine was very important to us,” Morhard explains. “For example, the G 250 can also be equipped with very small grinding wheels and worms.” In addition, the G 250 HS variant has a high-speed, 20,000-rpm grinding head if a small grinding worm is used.

According to the company, other advantages of this machine concept include:

- Generating grinding and profile grinding are performed on the same main grinding spindle, so the machine does not suffer from heat development (like when auxiliary spindles are used for profile grinding). Additionally, the machine can be retooled for the alternative procedure within a matter of minutes.

- Generating grinding can also be used for machining workpieces with interfering contours by using generating worms with a root diameter up to 68 mm. This results in very short grinding times. All other components can be finished with a small profile grinding wheel with a size of up to 30 mm.

- Centering takes place in the loading position, in parallel with the main machining operation.

- The integrated dressing unit helps process reliability.

The G 250 gear grinding machine has been specially designed for short cycle times for mass production of gears with an outer diameter up to 250 mm and shafts with a length of up to 550 mm.

For large components used in trucks or in general gear manufacturing, the G 400 is available for generating grinding. It is equipped with a tool table for components with a maximum diameter of 400 mm and a shaft length of up to 750 mm. The machine can also be loaded from above, because its housing has an over-the-corner door.

RELATED CONTENT

-

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

-

Should You Bring Tool Regrinding In-House?

In some situations, the potentially high investment in an in-house tool grinding process can be justified with a relatively fast ROI. (Includes video.)

-

A Race to the Machined Part (Surface) Finish

To improve component finish as well as engine and gearbox performance for its customers, this racing motorcycle rebuild company uses a super-finishing process for gears and related components which is more commonly used for aerospace and jewelry applications.