The Value of Mass Finishing, Shot Blasting for Aerospace and Medical Applications

The choice between mass finishing and shot blasting for CNC-machined parts depends on the specific requirements of the application.

#techbrief

The Value of CMM Controller Retrofits

In this case, new controllers for two coordinate measuring machines — one 26 years old — with new programming software offers the possibility to enable multisensor inspection of critical, turned aerospace components.

#techbrief

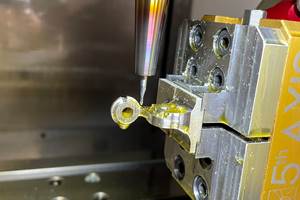

Addressing Micro-Boring Challenges

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

#techbrief #micromachining

Robotic Automation Options for Vertical Turning Centers

Custom robotic machine tending systems designed for specific high-volume machining applications can yield significant productivity and product flow benefits.

#techbrief #horizontal-and-vertical-lathes

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

#techbrief

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

#techbrief

Bar Feeder Designed with Swiss-Types in Mind

New technology enables this bar feeder to fully support the bar pusher and stock from inside the unit all the way to the spindle of a sliding headstock lathe.

#techbrief

German Project Yields Three New Medical Machining Processes

Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

#techbrief

CNC Rotary Transfer Machine Features Ballscrew Electromechanical Tooling Units

A CNC rotary transfer machine, a newly developed machine platform, is said to offer high rigidity, flexibility and accuracy for a range of high-volume, precision-machining applications.

#techbrief

Reaming as an Alternative to Single-Point Boring

Using slip yokes as an example, reaming through holes can be more efficient and effective than single-point boring operations.

#techbrief

The Case for Higher-Performing Metalworking Fluids

Machine shops have the opportunity to enhance their profitability by choosing the proper metalworking fluids for each machining application.

#techbrief #metalworkingfluids

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

#Industry40 #techbrief

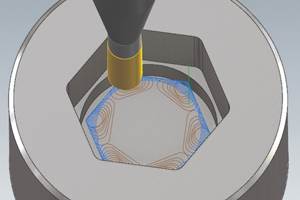

The Value of CAD/CAM and Cutting Tool Manufacturers Working Together

Overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges.

#techbrief

Streamlining Part Measurement, Data Collection Processes

When collecting measurement data automatically with a wireless data collection system, manual errors can be eliminated ensuring data accuracy and traceability.

#techbrief

The Advantages of Automated Shopfloor Gaging

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.

#techbrief

Automating Cutting Fluid Management

Automation can amplify the benefits of cutting fluid management while reducing the maintenance burden on shopfloor employees.

#techbrief #metalworkingfluids

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

#techbrief

Replace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

#techbrief

Video: Using AR for Remote Machine Tool Troubleshooting

Augmented reality can enable service engineers to help machine shops identify and possibly remedy issues with their machines remotely, perhaps eliminating the time and cost of an on-site diagnostic and maintenance visit.

#techbrief #Industry40

Tooling Considerations for Parting Off, Grooving

Geometry, coatings and tool holders all play a big role in the effectiveness of parting off and grooving operations on CNC turning centers.

#techbrief