The benefits of automation are potentially huge, but the investment required for a robot arm or pallet changer can be intimidating or even prohibitive. “Our customers wanted to get more usage out of their precision vises and felt they wanted to get into automation, but every time you start talking with those ballpark numbers jumping into $250,000 or $300,000 to do setups and vises, it scares so many off,” says Jon Dobosenski, general manager of Lang Technovation.

This inspired Lang’s Haubex system, which it designed to be a low-cost, simple way for shops to take a first step in automation by using a feature that’s already included on many milling machines — the toolchanger.

Featured Content

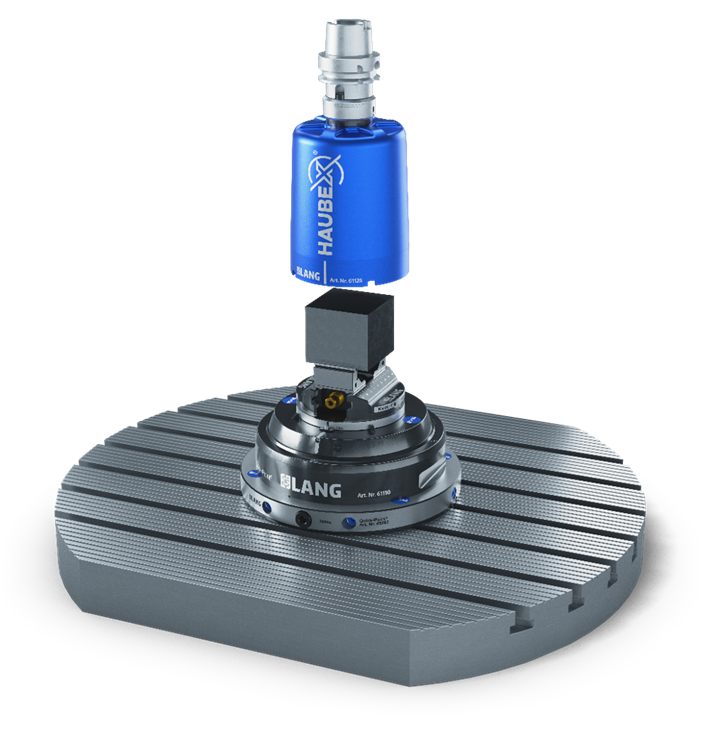

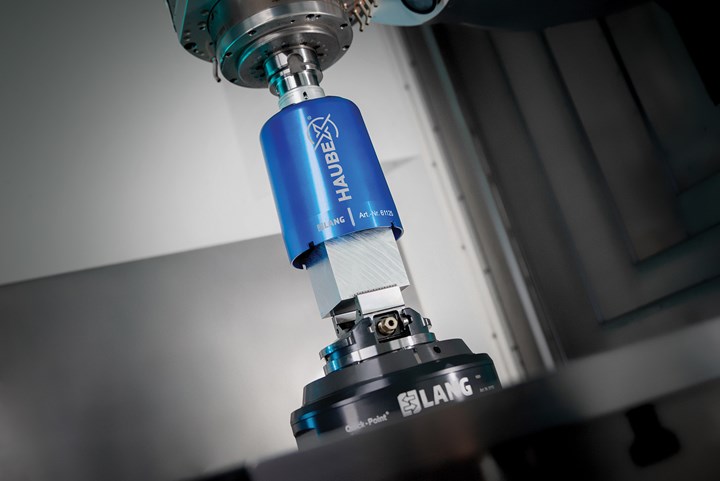

By using the toolchanger, a feature already included on many milling machines, Lang’s Haubex system can help shops take a first step into automation without high startup costs. The system stores blanks and finished parts in a milling machine’s toolchanger. Photo Credits: Lang Technovation.

The Right Tools for Automation

The Haubex system uses extra capacity in the toolchanger to store blanks and finished parts. Blanks are clamped into a vise, such as Lang’s Makro-Grip five-axis vise with a special platen, and covered with a specially designed workholding hood. The hood is locked into place with a 45-degree turn and placed into the tool’s magazine. Lang offers different spindle interfaces (BT-40, CAT-40, SK-40, HSK-63), but the system is compatible with other spindle interfaces as well.

When the machine is ready, the toolchanger places the hood (which contains the vise and workpiece) onto the Haubex zero-point clamping system on the machine table.

The spindle turns 90 degrees to lock the vise into the clamping system, then it removes the hood and places it back into the toolchanger, leaving the vise and blank in the machine. Lang provides the programs needed for the spindle to perform this rotation for several machine tool builders or alternatively, if the machine has a c-axis table, that can be rotated to lock the vise into place.

Key to this operation is Lang’s Quick-Point zero-point clamping system. The system sits on the machine’s zero-point plate on the table and uses pull studs to quickly and accurately mechanically clamp vises for machining. Dobosenski says that the zero-point clamping system has the benefit of being very easy to move in and out of the machine, enabling shops to run large parts or hot jobs during attended hours, then set up the zero-point clamping system to run the Haubex unattended.

This also means users can easily move the Haubex system, including zero-point clamping system, between machines for further flexibility. Shops may already be using a zero-point clamping system, which makes the Haubex even easier to implement. For shops using (or planning to use) another type of clamping system, Lang offers blank platens that connect with the receivers or custom fixtures.

Once the part has been machined, Lang then recommends using a combination of high-pressure coolant and a chip fan (such as its Clean-Tec model) following machining to clean the machine table.

This enables the hood to retrieve the vise from the Haubex clamping system and return it safely and securely back into the toolchanger so the next machining cycle can begin.

Blanks are clamped in a vise and covered with a workholding hood. When the machine is ready, the toolchanger places the part onto a zero-point clamping system on the worktable for machining. Then the workholding hood moves the finished part back into the toolchanger for storage.

Looking Under the Hood

Because the hood, vise and blank all must fit into the machine’s toolchanger, the size of the parts it can handle is restricted. The maximum blank size that can fit under the hood is 80 by 75 by 70 millimeters (or 3.15 by 2.95 by 2.76 inches). “It lends itself to smaller parts,” explains Dobosenski, “but the application is pretty unlimited as long as it can fit under that hood.”

Users also need to ensure the machine’s toolchanger can handle the weight of the hood, vise and blank. This is totally dependent on the machine, but Dobosenski expects this won’t be a significant issue. “A lot of our customers have large machines that can handle bigger tools and are underutilizing their toolchangers, so this helps increase their efficiency,” he says. Weight is really the only limitation on the type of machine tool that works with the system — it’s compatible with most three- to five-axis VMCs.

In addition to small parts, Lang identifies complex parts as a good fit for the Haubex, because the longer cycle times mean more unattended machining time. In fact, Dobosenski says that many customers have been using the system for medical and smaller aerospace parts.

The Haubex concept is flexible. One user stores blanks and finished parts on the machine table, off to the side of the clamping system, instead of in the toolchanger.

A Seat at the Table

If shops don’t have extra space in their toolchangers, the Haubex can still prove useful. One of Lang’s customers realized that, while it didn’t have room in the toolchanger, it did have free space on the machine table. So, instead of setting up blanks and vises with workholding hoods in the toolchanger, it set up the blanks and vises on the machine table, off to the side of the clamping system.

“Because the parts are small, it doesn’t encompass that big of an area on the table,” Dobosenski notes. This enables the user to set up multiple parts on the table. The user then only needs to keep a single workholding hood in the toolchanger for all its parts, using this hood to move the workpieces and vises from the table to the clamping system and back.

Dobosenski thinks this is just the beginning for finding new ways to use the Haubex. “I'm sure we're going to see a lot more creative ideas come out of this,” he says. “And we always love to see them because when you get a customer thinking outside the box, that's probably the best thing that you could ever see. Your design is around one concept and all of a sudden, more doors are opened up.”

— Julia Hider is senior editor of Gardner Business Media brand’s Modern Machine Shop.

RELATED CONTENT

-

The Advantages of Automated Shopfloor Gaging

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.

-

Robotic Automation Options for Vertical Turning Centers

Custom robotic machine tending systems designed for specific high-volume machining applications can yield significant productivity and product flow benefits.

-

Automating Cutting Fluid Management

Automation can amplify the benefits of cutting fluid management while reducing the maintenance burden on shopfloor employees.