One of the first clues that Precision Plus is different from other machine shops was a gentle clicking noise. The sound emanates from more than a dozen mechanically driven Swiss-type lathes at the center of the shop floor. Lined up in neat rows and serviced by obviously newer bar feeders, these machines cut uncovered, without the noise-damping enclosures that characterize the shop’s CNC machines. A closer look reveals a half-dozen or so tools simultaneously plunging in and out of the workpiece as the cams rotate.

Here, Mike Reader stands next to a Miyano BNX twin-spindle CNC lathe. Mike is in charge of the shop’s apprenticeship program, which trains new employees in the use of Swiss-type screw machines. Photo Credit: Precision Plus

Some of these machines had already been producing parts for years by the time the company moved to its current location in Elkhorn, Wisconsin in 2000. Under the leadership of company president Mike J. Reader, the company has since added various newer CNC equipment, including Miyano ABX and BNX two-spindle lathes as well as multiple Star and Tsugami Swiss-type CNC lathes. And yet, Precision Plus still relies heavily on equipment that operates in much the same way as it did when Reader’s father, Phil, first purchased the company in 1988 – that is, by using physical cams rather than CNCs to space out the timing and depth of cuts. Why?

Featured Content

This was my first question to Michael P. Reader, VP of Engineering (and Mike Reader’s son). His answer was simple: “The cam-driven machines, when they can be used, are cheaper to operate,” he says.

Choosing Cams Over CAM

Small precision parts, such as this screw for oboes and bassoons, are ideal for cam-driven machines. The groove is cut by a saw blade attached to the pick-off attachment. Photo Credit: Precision Plus

“For small cylindrical parts with higher annual volumes, the Swiss cam machines are very economical,” says Reader. The fleet of mechanically driven Swiss-type lathes from Tornos have lower electrical costs and crucially can often cut parts significantly faster.

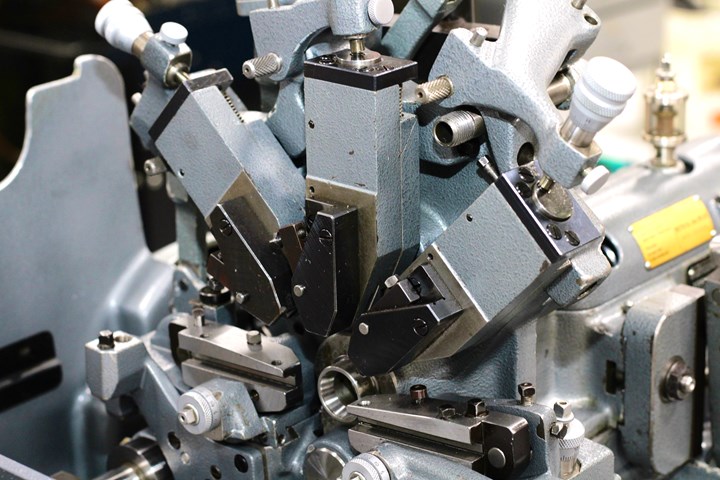

That last factor might be surprising to some, as a computer-operated machine tool seems like it should have no problem competing with a machine that has absolutely no computing power whatsoever. However, the cam-driven machines can utilize multiple cutting tools at once, with very little travel. “All the tools are at rest less than two inches from the part,” Reader says, gesturing to a semicircle of cutting tools frantically cutting a firing pin out of a thin bar. “This makes it much faster than a CNC.”

Five cutting tools surround the workpiece on this cam-driven, Swiss-type screw machine. As the camshaft turns, the different cutting tools perform their operations and cut a finished part once per rotation of the shaft. The close positioning of the cutting tools relative to the workpiece makes it an excellent option for quickly producing parts with only a few features. Photo Credit: Precision Plus

How much faster could it be? “We have one part that would take eight seconds per piece on a Swiss CNC,” Reader says. “On the cam machine, it takes three seconds.” More than doubling production speed is a major difference, especially when dealing with high volumes. “If we had to use a CNC on that part,” he says, “we wouldn’t even break even.”

But when are the CNC machines preferable?

Precision and Tolerance on the CNC

Another benefit from the cam-operated Tornos machines? The visuals. “The Swiss cam machines are easily accessible, so you can see what’s happening,” Reader says. This makes them perfect for the company’s apprenticeship program, which Reader credits with delivering a workforce. Photo Credit: Precision Plus

“It really depends on the needs of the part,” Reader says. “Some parts need increased precision, which a Swiss CNC provides.” Take the example of a dental component the facility produces. At one end, the diameter is only 0.01 inches thick, and its length-to-diameter ratio is quite high, so it requires additional support to eliminate chatter and prevent breaking the component off in the machine. These features of the part make the CNC necessary, as it is capable of higher precision and greater rigidity. Additionally, surface roughness must be nearly flawless, as a slight imperfection can be catastrophic. “We need to make sure we hit the tolerance exactly,” Reader says. “If this dental component had any surface imperfections, it could lead to crack propagation and failure during use.”

I think anyone who has sat in a dentist’s chair is grateful for the increased precision of the CNC machine.

This dental component must meet exacting tolerances and has a large length-to-diameter ratio, making it necessary to use a CNC Swiss-type turning machine rather than a cam-driven one. Photo Credit: Precision Plus

Factors other than tolerance can play into the choice to use the CNC machines. For starters, they can handle larger parts – 12, 20 or 32 millimeters, depending on the machine. Additionally, parts like the dental component require high-pressure coolant, which is not possible in the cam-driven Swiss lathes. Coolant can also be a major factor for materials that generate stringy or sticky chips, as well as valve components with O-ring’s grooves that require high pressure to remove chips.

Finally, the headstock lathes find work with larger and more complex parts up to 2.5 inches in diameter. “Generally, when we have lots of material removal or a higher degree of complexity, we’re going to utilize our Miyano platform,” Reader says. The Miyano ABX is used for aggressive and precise machining – in part due to the hydraulically operated chucks and the robust machine design the platform offers. One part used in semiconductor production involves a great deal of ID material removal, off-center drilling, threading and OD turning on high-tensile, high-yield stainless steel. On a two-spindle lathe with three turrets, the component can be machined complete in one operation at a highly competitive rate.

Used in manufacturing semiconductors, this part is better suited to the traditional lathe. It involves multiple off-center drilling operations, heavy ID material removal, and several exterior features – all in a difficult-to-machine stainless steel alloy. Photo Credit: Precision Plus

The other lathe – the Miyano BNX – is primarily there for its efficiency. “The BNX offers faster production rates than the ABX while also allowing for fifth-decimal offsets,” Reader says. Precision Plus machines components plus-or-minus 1 ten-thousandth of an inch on OD turning, and a total of 3 ten-thousandths on ID bores. When it does not need to be quite so precise, it is capable of machining simultaneously on the main and sub-spindle with the single turret, which increases throughput on many parts. Both platforms are equipped with quick-change chucking systems from Hainbuch to improve setup time and part concentricity from spindle to spindle.

As with many things in machining, it really comes down to the part. “In general, the larger and more complex the part, the more likely it is to go on the fixed headstock lathes,” Reader says. “Smaller cylindrical parts with extremely tight tolerances or that need high-pressure coolant go on the Swiss CNC machines. But if we can make it on the Swiss CAM machines, it will likely be faster, and just as precise, to be produced there.”

RELATED CONTENT

-

Precision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

-

Swiss-Type Machines: More Than Just a Lathe

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.