Swiss-Type Machines: More Than Just a Lathe

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.

When someone asks me what I do for work, I can never give them a short and simple answer. It’s difficult to explain to someone outside the precision parts manufacturing industry that I help customers get the most of out of their Swiss-type machines and allow them to do more than what they may expect. That is actually the short and simple answer. For many years now, Swiss turning has distanced itself from the “it’s a lathe” label. Shop owners and machine operators know that.

Thanks to CNC technology and its ongoing improvements—machine design, tooling innovations, competition, parts producing cost pressures and myriad application challenges—the capabilities of Swiss-type CNC machines have expanded. They are truly much more than just a lathe; they go way beyond the ability to produce more than screws. Today’s machines are fully equipped, bar-fed machining centers that are capable of making complete parts, some of which can have long lengths, greater than three times the diameter. They are also capable of making parts that one may not even consider to be a “turned” part.

Featured Content

This can partially be attributed to the addition of new innovations with live milling and drilling spindles, indexable turrets and advanced axis controls. However, what gives these machines the edge to produce better parts is the new tooling and accessories that are now available to perform cost-effective machining “wizardry,” from barstock to finished parts, using one machine.

Thread Whirling

Thread whirling is one example of where new developments in tooling are playing a critical role in meeting both production and quality demands that impact cost and maximize machine tool use. Currently, the medical manufacturing industry is fueling the need for new and more productive thread whirling tooling to efficiently meet the ongoing requirement of special deep thread forms on bone screws and implantation appliances.

Many Swiss-type machine users use single-point threading of these forms resulting in many time consuming passes to reach the root diameter of the thread. Also, usually because of the length of the threaded portion of the part, single-point threading may not be an advisable option since it requires retracting the part back through the guide bushing several times. This process results in an unsupported workpiece (defeating the purpose of the guide bushing), causing quality and accuracy problems.

Thread whirling solves this problem by taking stock diameter to finished threads in a single pass, performing all the cutting close to the guide bushing to ensure proper support. Thread whirling is not a new process. However, recent advancements such as faster spindles and unique 12-insert cutter rings have enabled medical manufacturers to make threaded parts as much as six times faster than previous methods. For example, we have partnered with Swiss tooling maker, UTILIS, in developing and producing this type of tooling system for the U.S. market to help it step up medical device production. Whirling inserts generally have a stronger cutting edge versus a single-point tool, since side clearances are achieved by installing the whirling spindle at the required helix angle rather than removing supporting material behind the cutting edge.

By switching to the advanced 12-insert system, a user can benefit from at least a 25-percent increase in productivity just from increased insert life alone. Insert change-over is made easy by inherent repeatability of tight-tolerance indexable carbide inserts and modular design of the cutting insert ring itself.

High-Pressure Coolant

Common to aerospace and medical industries are applications where tight tolerances must be held while machining tough, high-temperature alloys or exotic metals. These materials may be subject to work hardening, or may create stringy, hard to control chips when turned. One solution to this problem may be a high-pressure coolant pump.

High-pressure pumps can be easily integrated into a machine’s coolant system and are controlled by the CNC program. The system has proven itself invaluable in high-speed drilling and milling, deep boring operations or turning of stringy materials such as 17-4PH stainless. Used properly, jets of high-pressure (about 2,000 psi) coolant quickly evacuate chips from the cutting areas, resulting in increased tool performance and life for both OD and ID working tools.

In addition, surface finish and quality can be tightly controlled, and in many cases, speeds and feeds can be increased providing faster cycle times, resulting in delivery of more completed parts by the end of the day. The overall value of adding high-pressure coolant to a Swiss-type machine is almost incalculable when one considers the tool savings and increased productivity a system such as this provides.

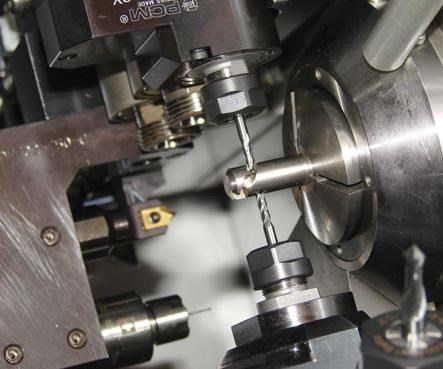

Rotary Broaching

A cutting operation that has been in use for many years, but recently has realized new improvements is rotary broaching, because of collaboration between PCM Willen of Switzerland and Genevieve Swiss. The rotary broaching process enables polygon-shaped drive features to be quickly machined in parts without stopping the machine’s spindle.

The new system, specifically designed for Swiss-type CNC machines, employs a low-profile holder that does not require center adjusting, sets up in minutes and fits easily into almost any Swiss-type machine without sacrificing the use of adjacent tool stations. The on-center design of the holder, when combined with tightly controlled broaching tools, provides quick change-over of tools and high repeatability part to part, even following tool replacement. In addition, this enables the machine to maximize productivity without subtracting tool positions just to fit the specialized broaching holder.

Most free machining metals can be broached in a Swiss machine, ideally ranging in sizes from 0.050 inch to about 0.375 inch. Many broaching applications performed in Swiss-type machines are generally applied to medical applications and aerospace fasteners, but a rotary broaching system may be an excellent choice for anyone who is interested in saving time and money as the process eliminates having to perform a secondary operation to achieve the final polygonal profile.

High-Speed Drilling and Milling

Swiss-type machines are well known for their accuracy thanks to the sliding headstock/guide bushing design, which provides more workholding stability at the point of machining. This design excels at the manufacture of long, slender parts because all the cutting forces occur only a few millimeters from the guide bushing. This axial support helps to reduce vibration and deflection. It also enables tight tolerances to be held on high-precision parts.

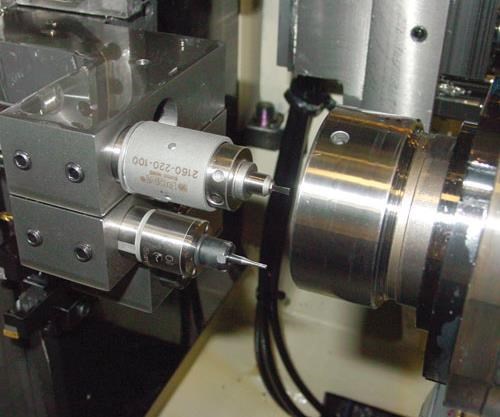

When a small part calls for several milled or drilled features, one could be looking at long cycle times since live tool spindles incorporated into many Swiss-type machines cannot run at high enough rpms to achieve the desired surface footage to allow high feed rates for micro-tools. To alleviate this, many shops look to aftermarket accessory manufacturers for high-speed spindle units that can be added to their Swiss machines’ setup that would allow them to reach the “sweet spot” in terms of speeds and feeds.

These new high-speed spindle units are completely integrated into the machine and can be powered by pneumatic air lines or electricity, or they can be direct OEM replacements where they are driven by the machine’s live tool motor. Each type of high-speed spindle unit works well for increasing the surface footage of micro-tools. However, gear-driven OEM replacement units should not be dismissed as an option. They bring simplicity of installation, setup and torque delivery to the application.

Gear-driven, high-speed spindles use a gearbox/transmission to multiply the spindle speed the program is set at, making it easy to use and program. Direct fit spindles are also simple to set up and tear down, making transfer between jobs quicker. Electric and air spindles have air lines and wires that need to be installed onto the machine in such a way that they will not interfere with the machine’s movement or become chip collecting hazards. Also, once an air or electric spindle system is integrated, it is not conveniently removed should it be required for a different job on another machine.

Directly driven high-speed units also allow for application flexibility as they can be programmed to run at normal speeds without any loss in power. They also can be used for time-saving processes such as high-speed “pinch” milling. When a machine has an indexable turret equipped with live tooling, a turret station can provide simultaneous machining to the gang-slide mounted spindles.

This configuration results in the ability to complete a complex milling operation significantly faster than if the operation was performed with one standard spindle alone. As an example, PCM/Genevieve has recently introduced a new high-speed spindle design for the turret of the Citizen M20 and 32, which enables users to perform high-speed pinch milling in this fashion. The new spindle design features an offset, which places the tool closer to the guide bushing for added support and allows for alignment with the gang tool stations.

In today’s machining environment where speed and productivity are more important than ever, a shop really has no excuse for not using some form of high-speed spindle unit to satisfy production pressures.

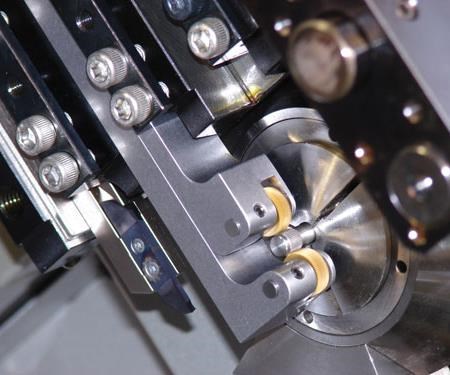

Swiss-Type Knurling

Often times, small components typically made in Swiss machines call for knurled features. As most machinists are aware, knurling requires significant forces to be applied to the workpiece in order to get the desired result. This simple fact combined with the inherent small-diameter parts typically encountered in Swiss machining makes conventional “bump” knurling methods undesirable as the forces will deflect the workpiece.

To control this problem, a straddle knurl holder should be used to provide support to the workpiece while the knurling operation is performed. Low-profile straddle knurling holders are adjustable to accommodate a range of sizes, usually from the smallest knurled piece to about 0.75 inch. Specifically designed for Swiss-type machines, low-profile straddle knurl holders keep interference to a minimum within the tooling envelope of most machines while ensuring adjacent tool positions are available to maximize tooling capacity. When combined with convex series knurl dies for axial feeding (Z axis), a compact straddle knurl provides the Swiss machinist with a robust solution for small-parts knurling.

Don’t Stand Still

There’s no guarantee that every Swiss-type machine user out there is experiencing machining “wizardry” day in and day out. But there is no doubt in order to remain competitive, machine builders, users and tool engineers are continually challenged by new applications, plus the need to improve upon existing ones. New tooling designs, properly applied accessories and process improvements can often provide a direct path to enhanced productivity in terms of lower costs and higher quality, all within existing Swiss-type machines on the shop floor. In this sense, Swiss-type machines continue to be more than “just a lathe.”

RELATED CONTENT

-

Adding 5-Axis Capability to a 3-Axis CNC Mill

This attachment provides shops using thee-axis machining centers the option of on-demand four- and five-axis machining.

-

Diamond Lapping and Lapping Plate Control

The word “diamond” brings the word “expensive” to mind. But when it comes to lapping with diamond superabrasives, start thinking “low”—as in lower slurry consumption, lower slurry cost per hour, lower sludge generation, lower cycle time, lower reject rates and fewer process steps.

-

Get 5-Axis Machining on a 3-Axis VMC

Machine shops want and need to eliminate steps in the manufacturing process. Adding four- or five-axis capability to an existing three-axis VMC is a practical way to achieve five-sided machining using a single setup.