Editorial, News, and Products

RW Screw: Where Automating Processes is a Common Thread

This Northern Ohio contract machine shop increasingly integrates automation, in all its forms, as it adapts to the reality of a continually diminishing talent pool.

Mini Clamping Device Changeover System Provides Actuation With One Screw

IMTS22: The clamping device is said to enable changeovers in less than one minute.

The Right (Machine) Tool for the Right Job

This high-production shop uses both mechanical and CNC Swiss machines to make parts, but which machine is right for which job?

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.

Precision Machining Technology Review May 2021: Workholding

Production Machining’s May Product Showcase includes new workholding equipment from Hainbuch, SMW Autoblok, Schunk, Northfield Precision and Ringspann Corp.

Custom Tooling, Workholding Help Whip Rotors Into Shape

Whipple Superchargers uses unique form tools and dead-length-collet workholding for its B-axis turn-mill enabling it to create more accurate rotors for its brand of engine power-adders.

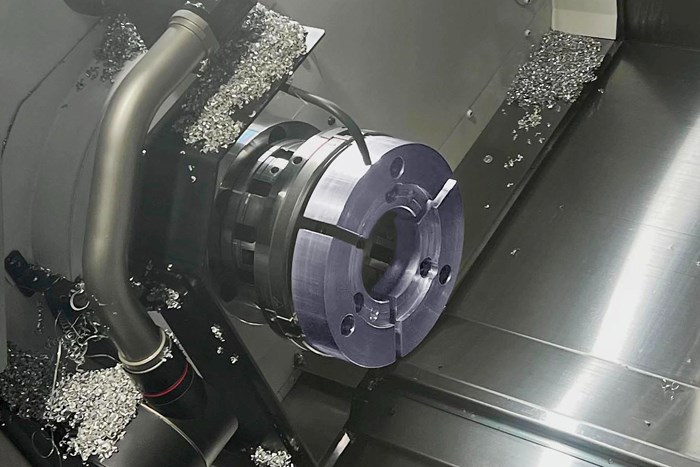

Hainbuch’s Centrotex S Part Clamping System Designed for Small Workspaces

Mini clamping device changeover system requires less tightening torque to speed up assembly and reduce changeover times.

Hainbuch 2-Jaw Module Adapts to Clamp Cubic Parts

The 2-Jaw module delivers small alternative to large centric vice.

Hainbuch Mini-Chuck Designed for Accessibility

PMTS 2019: Hainbuch’s TOPlus mini-hexagonal collet chuck is designed for tool accessibility by reducing the profile contour.

Workholding Trend Adds Flexibility

There’s been a workholding trend in Europe for turned parts that consists of improving the flexibility of gripping on the ID or OD of a workpiece.

Precision Workholding Delivers Accuracy and Production Capabilities

Holding the workpiece precisely is becoming an integral aspect of the machining process. It's more than presenting the blank to the cutter; it also includes repeatability from blank to blank.

PMTS 2017 Slideshow

The ninth Precision Machining Technology Show (PMTS) opened yesterday to record crowds and the largest exhibit hall in show history. Here are some photos from the first day and a half. There's still time to attend the precision machining industry's signature event. Register Today at PMTS.com.

Precision Workholding Keeps Quality High for Gun Manufacturer

Keeping up with the latest and best processes is important for any shop, even one that produces a product that has been manufactured since the Industrial Revolution.

Include Workholding in Your Process Planning

Manufacturing has seen a tremendous renaissance in North America. Increasing demand for shorter contracts and lower volume requirements has generated manufacturing strategies.

Precision Workholding Offers Multiple Advantages

As American manufacturing continues to transition from the mass production of conventional parts to the manufacture of complex, high-value components in relatively small lot sizes, precision workholding has assumed increased importance

Making it in America

For years, I’ve used the maxim “Showing up is 80 percent of the job.” Recently, I was able to “show up” at the workholding manufacturer Hainbuch’s headquarters in Marbach, Germany.

Clamping System Reduces Machining Time and Setup

The staff at Rodriquez GmbH in Eschweiler, Luxembourg (Germany), has been relying on a Hermle C40 milling machine equipped with the Hainbuch Quadrok Plus clamping system for the manufacturing of linear technology components.

Grip it on the ID

For many turning applications, gripping on the ID of a center bore can provide processing benefits.

Clamping Devices Ensure Power Boost for Turbo Manufacturer

In order to efficiently manufacture more than 12,000 toothed parts with a range of dimensions having lot sizes of 1 to 50, a shop needs to focus not only on the cutting parameters, but also developing a strategy for handling the tremendous setup time.

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

The Right Clamp Makes a Difference

Clamping has often proven to be the Achilles heel of hard machining.

Change This Chuck: Save Setup Time

Quick change workholding is one way shops are reducing setup when dealing with higher-mix/ lower-voulme work.

Faster Change-Overs Allow Focus On Machining

A creative Midwestern shop shows that its productivity edge runs all the way down to its relationships with vendor partners. With the right clamping and centering device, the company has been able to reduce workpiece change-over times by as much as 50 percent while improving rigidity and precision.