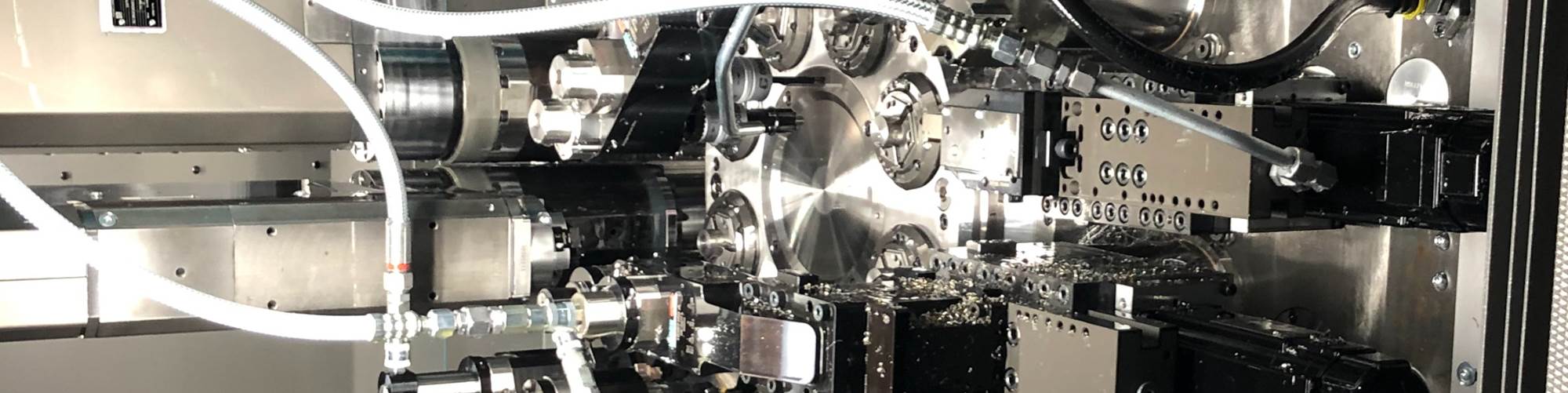

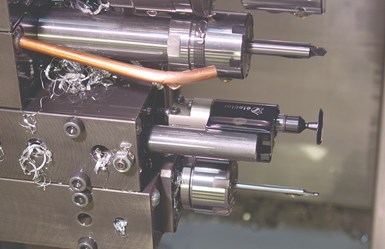

The Index MS32-6 multi-spindle lathe features the company’s new tool slide platform that uses a W-serration interface and quick-clamping system to enable fast changeovers.

My “Chasing Threads” column here lays out the reasoning for this article. In short, while the physical International Manufacturing Technology Show (IMTS) isn’t happening this month, software and equipment suppliers have been gearing up to unveil new offerings about this time that can help shops like yours become more efficient and effective operations.

That’s why I reached out to a number of suppliers to our precision machining industry that support the show to hear about the trends they’ve spotted and how their new technology is designed to meet the challenges those trends present. The two trends that most clearly emerged after my discussions with many of them were automation is more than robotics, and high-volume production machining equipment is becoming more flexible. Along those lines, what follows are snippets introducing technology that can enable shops to excel as they set up their businesses to best serve customers’ needs.

Shopfloor Automation Comes in Various Forms

When some hear the word “automation” in the context of its role in a machine shop environment, a robot immediately comes to mind. Certainly, machine-tending robots are becoming more prevalent in shops. And the value of such automated production has been particularly evident as shops have been presented with human resource challenges as a result of COVID-19. Not surprisingly, machine tool builders are increasingly being asked about automation options that are available with their equipment.

This includes Marubeni Citizen-Cincom. Its Citizen Swiss-types can be fitted with vacuum ejection, wire ejection and pallet loading/unloading units for automated part handling. Vacuum systems eject parts from the subspindle and into a vacuum extractor, which are collected in an external tray or carousel. Well-suited for medical applications, wire ejection systems are designed to eject long, delicate parts and include a part collection tray or table. Palletizing systems enable in-process collection and component sampling, while a shuttle storage tray unit can be accessed during machining process to unload completed components. It is also possible to automatically load material into the machine’s spindle.

Marubeni Citizen-Cincom now offers B-axis automated tool changing capability for its L20XII ATC Swiss-types that can accommodate 13 tools.

The company also now offers automated tool changing capability for its B-axis L20XII ATC Swiss-types (as shown in the video below). Tools mount on the gang toolpost and can accommodate 13 front-machining B-axis tools (12 of which are stored in the ATC). The ATC tools can be used in conjunction with existing turning tools and cross-machining rotary tools. They can be preset offline for fast setups, while enabling the complete machining of complex geometry as is common to medical implants.

Magazine bar feeders are easily deployed automation tools. For example, Edge Technologies’ new Edge Patriot 880 (for diameters ranging from 8 to 80 mm and available in 6- and 12-foot versions) features quick-change guide channels and an adjustable roller steady rest. The company says it fills a market need for a robust, affordable solution for large-diameter barstock. The 6-foot version is said to benefit users who want more functionality than a conventional short loader in being able to feed 6-foot bars with remnant retraction.

CAM programming can also be automated, and DP Technology has been refining its artificial intelligence (AI) engine to enable that. The goal is to “build intelligence” and integrate best programming practices using a database of information that experienced programmers have honed over time.

DP’s latest version of Esprit software includes functions such as Machine Swap, which leverages the digital twin concept whereby a digital replica of the entirety of a machining operation is created in a virtual environment. The company says this capability is good for shops that have many different machine types. For instance, it is said that a part program created for a VMC could be created to run the job on an HMC, with the AI engine automatically generating the new code because it knows that HMC’s kinematics. Similarly, with the Automatic Link function, the AI engine can create the optimal, safe linking of cutting operations, adjusting movements as workpiece material is removed and tool clearance distances change to speed cycle times.

Esprit uses an artificial intelligence engine as a means to “build intelligence” into CAM programming for a range of machine tools including Swiss-types. Creating accurate, digital twins of actual machines with data of machine kinematics is a key part of this, too.

But, the company also works closely with machine tool builders and dealers so that postprocessors can be developed that require no manual code editing. It says this can be an equally big time saver for programmers.

Star CNC says with unattended machining continuing to evolve comes increased need for process monitoring and predictive analytics to support lightly or fully unattended operation. Its new SMOOSS-i software is said to enable remote monitoring via live data collection as well as up to-the-minute status of job completions. Other software features can help anticipate required operator attention based on tool life and condition, remaining available raw material and current machine status. This helps better determine when an operator is required to be at a particular machine to better manage his/her time and presence. Given the current social distancing recommendations due to COVID-19, this can also minimize the number of people gathering in any one area.

The Detector series from SPC Innovations features a modular design that is said to offer easy calibration and configuration of various sensors based on a specific part while enabling the system to be installed on other machines.

Similarly, in order to establish confidence in unattended machining processes, parts must be regularly measured for dimensional control and tools as well to detect wear and breakage. SPC Innovations now offers its Detector in-machine broken tool and part gaging system. The system consists of a universal industrial touchscreen that can be used to program and monitor wand-type, electronic contact sensors with encoders that are configured for either tool/part presence or part measurement. In-process part measurement of critical part attributes enables automatic changes to tool offsets to compensate for tool wear. It can also automatically reject parts found to be bad due to an anomaly such as a misload.

The new system accommodates as many as 16 sensors. The machine’s own material handling capability can be used to move a part to a sensor or a cross slide can be created to bring a sensor to a part to measure its diameter, length and more. The modular design is said to offer easy calibration and configuration of various sensors based on a specific part and enable the system to be installed on other machines. Plus, such automatic in-machine inspection can remove a significant amount of manual part sorting and measurement, and physical contact with the parts.

Production Equipment Can Be Flexible

Transfer machines are well-known options for high-volume machining work. Builders such as Gnutti, however, are also designing their machines with flexibility in mind. For example, its Piccola machine processes coil stock in diameters as large as 13 mm. Machining from coil eliminates the need to change to new barstock sizes and enables shops to realize high material usage as there is no barstock remnant. But, in addition, the Piccola machine has a new multiple-station, tool change system that can accommodate as many as six tools. This offers versatility to run different jobs or have redundant tooling for long-running jobs.

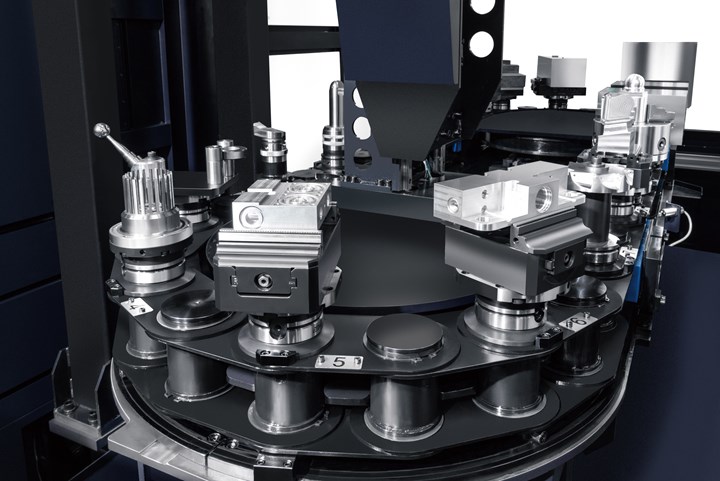

Hwacheon says it is seeing increased interest in automated solutions for highly complex parts such as those produced on its D2-5AX five-axis machine. This automatic workpiece changer that can be fitted to such a machine is available in eight or 20-station models and can accommodate parts with a maximum diameter of 300 mm and weight of 80 kg.

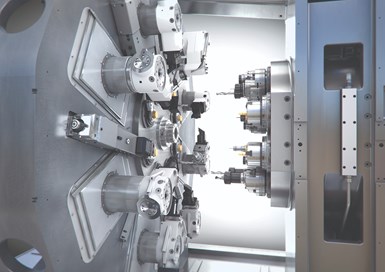

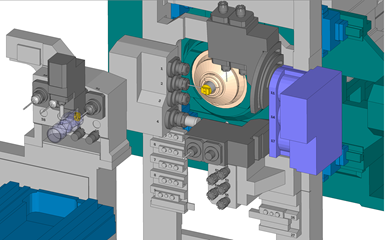

With its MultiX rotary transfer platform, Mikron says it has placed the emphasis on its configurability, scalability and flexibility. These machines offer true turning capabilities and the ability to have up to three tools in the cut in one station (a machine can have 4-24 stations). All standard machining units are exchangeable and very precisely repositionable. Therefore, a machine configured for one job can be reconfigured for another job by exchanging machining units. In addition, different toolholders are available and multiple tools can be mounted on each unit.

Porta’s PortaCenter concept was also developed to meet the needs of high-mix production as the company says the total volume of parts needed continues to rise, but the lot sizes are shrinking. These standard model machines have three 4-axis machining stations and one load/unload station and offer — in a single unit — an alternative to multiple, conventional 4-axis horizontal machining centers (HMCs). This is said to reduce costs related to fixturing, tooling, labor, floor space, inspection and utilities, while providing fast changeovers to new jobs. In fact, the company says the PortaCenter’s additional A- and U-axes enable it to machine parts in one setup that a conventional HMC cannot. The standard PortaCenter ISO40 model offers a 10” work envelope, while the company also offers its ISO50 model, which has a 20” work envelope to accommodate larger parts.

An alternative when barstock size starts to push a Swiss-type’s capacity, this Doosan Puma TT-1300SYYB with twin turrets each with Y-axis movement can approach the main and subspindles separately or simultaneously.

Shops familiar with Swiss-types also have choices to make when jobs start pushing or exceeding the barstock capacity of those machines. Doosan says its new Puma TT-1300SYYB model offers the productivity, precision and flexibility for parts of that can be produced from 2-inch barstock. This machine has twin turrets each with Y-axis movement that can approach the main and subspindles separately or simultaneously, the latter for operations such as pinch turning.

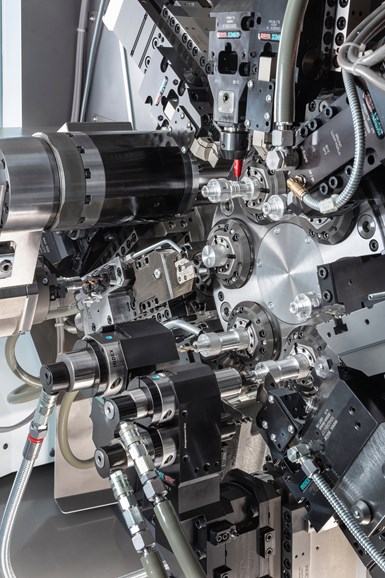

For smaller parts, Index now offers its new MS32-6 multi-spindle lathe (shown at the top of this page), which is said to open the option of multi-spindle technology to a broader range of shops. This machine includes the company’s new tool slide platform that uses a W-serration interface to enable fast changeovers with precision locating. Additionally, a new quick-clamping system is said to make it easy to bring in tools that have been set up offline. Index says the combination of these features can cut setup times by more than 90%, enabling shops to achieve the high productivity multi-spindles are known for with versatility to run smaller lot sizes.

Tornos now offers its small-footprint SwissNano machines in a larger 7-mm-diameter model.

Tornos has similarly boosted the flexibility of its small-footprint SwissNano Swiss-types with its larger 7-mm-diameter version. This model features the same thermal stability and 6-axis kinematics design with back spindle mounted on three linear axes of the original 4-mm model, but also has twice the spindle power (2.5 kW) to machine more exotic materials. Plus, two, three or four tools can be fitted under the counter spindle, enabling the machine to perform operations in parallel.

Horn offers the W&F Linear unit with integrated coolant management system for Swiss-types. This unit has specially designed plumbing that enables the user to run high-pressure coolant to the toolholders by simply connecting two lines to unit ports.

Quick-change tooling is also available to increase the flexibility of production machine tools such as Swiss-types to more readily accommodate smaller batch sizes. For example, Tsugami says it offers both driven and static tool holders that can be preset outside of the machine and changed in a matter of seconds, eliminating the chance for operator error in touching off tools. This can also greatly reduce the need for secondary operations as well as encourage the use of redundant tooling and lights-out machining.

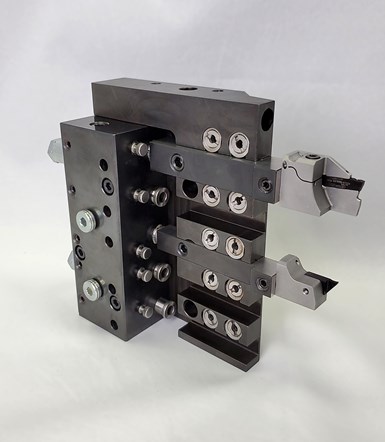

Horn has partnered with W&F Werkzeugtechnik to offer the W&F Linear unit with integrated coolant management system for Swiss-types for faster setups. Horn says that while this quick-change offering was not first to market, it does solve the stability challenges inherent with the stringent requirements of Swiss machining as well as address the tight work envelope, which otherwise might lead to additional time to change tools.

According to the company, changing out a tool on a Swiss-type often means truing the cutting edge and plumbing the toolholder if there is through-coolant. Truing can be time consuming and, because it involves positioning the tool against a part’s OD, overtightening the toolholder can also chip the edge of the cutting tool. Instead, the W&F Linear system is a direct bolt-on block customized to replace the tool block of the user’s specific machine. The block has specially designed plumbing that enables the user to run high-pressure coolant by simply connecting two lines to ports on the block. The coolant is fed through the block and through HSK coolant tubes into the toolholders, which plug into plumbing ports at the bottom of each tool station.

The plumbing ports also provide a fixed distance for establishing the position of the cutting tool. The ports serve as stoppers, as the toolholder rests against them even when there is no through coolant. Because the length of the toolholder is known and the stopper provides an exact position, the user can establish the position of a cutting edge without needing to true it. Tool changes are then a matter of pulling one toolholder out, replacing the insert and plugging it back in.

Tool changeouts for CNC milling machines aren’t as problematic as they have automatic tool changers (ATCs). But, for shops looking to use high-speed spindles to provide the rpms to enable a conventional machine to perform micro work — a market that NSK says is growing— some operator intervention can be required.

Quick-change workholding is becoming more commonplace to speed setups in high-mix production environments. Hainbuch has recently added a two-jaw module for its systems to enable clamping on cubic parts.

According to the company, small-diameter tools typically require spindle speeds of 15,000 rpm or higher, speeds conventional machines often cannot achieve. One type of high-speed spindle, which installs in a machine’s own spindle, is an electric model. NSK says electric spindles are advantageous in that they interface simply with a machine’s CNC and offer long life, consistent speed, high accuracy and good repeatability. The drawback for traditional electric spindles is that, while they can be stored in an ATC pocket, an operator must stop the machine to disconnect the electric signal and pneumatic air line used for cooling and purging before the spindle can be loaded into the ATC. The company’s latest models are fully changeable without the need to manually connect or disconnect those elements. This provides the flexibility for a low-rpm machine to achieve the high rpms needed for micromachining when needed. NSK’s electric spindles can reach 80,000 rpm.

More on the Horizon (As Always)

This technology sampling is just that — a sampling. No single article can be so encompassing as to touch on all that’s newly available to the precision machining industry. As always, Production Machining will continue to introduce helpful new equipment, software and concepts as they are developed. We also look forward to continuing to take deeper dives into topics such as those mentioned in this article as well as crafting stories describing how advanced technology is successfully being applied in shops like yours. Subscribe for your print copy.

RELATED CONTENT

-

A Different Kind of Machining Center

If one horizontal machining center is good, then three on a single platform should be better, right? That’s the thinking behind the Multicenter concept from Italian builder, Porta Solutions. It blends the volume production capabilities of rotary transfer technology with the flexibility of a machining center in a single platform.

-

Rotary Transfer Reduces Manufacturing Steps and Opens Opportunities

This Ohio shop has installed rotary transfer machines to reduce multiple step processing, which has increased production capacity.

-

Rotary Transfer Machines Help Shop Make Transition

Camcraft Precision Machined Components purchased two rotary transfer machines from Hydromat Inc. after winning a bid on an automotive plunger.