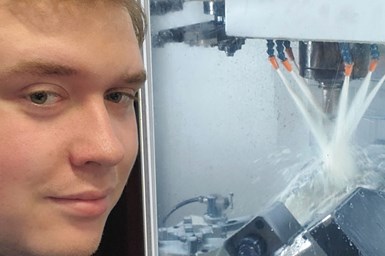

Emerging Leader Jesse Ziegler strongly believes in in-house training for operators/machinists. Therefore, he has created his own training program to ensure that Swissturn staff members are trained to handle any situation that occurs at the machine tool. Photo credit: Swissturn/USA

Highlighting professionals under the age of 40 who shine in their precision machining organizations and their communities as leaders is refreshing in an industry that is plagued with an ongoing skills gap. Reading stories about how these young leaders solve problems with their creative and thoughtful initiatives reminds us that the industry’s future success is in good hands.

As I am every year when gathering information from the Production Machining Emerging Leaders, I am once again impressed with the 2021 winners’ talents, expertise, professionalism and passion for their careers. My interviews with them revealed insight on handling workforce development and continuous improvement within their companies, which is valuable for any manufacturing facility. They touched on topics such as working with local trade schools, hiring strategies, training, lean manufacturing, creating more efficient processes and more. These are lessons all shops should consider adopting in their machining businesses.

Featured Content

Community Education/Educating the Community

The phrase “it takes a village to raise a child” is true in many ways, and this adage can refer to helping young people choose the right career path, too. Therefore, educating the community about manufacturing careers and involving the community is critical to teaching our youth about these rewarding and lucrative occupations.

Emerging Leader Kylan Hastreiter has discovered the importance of uniting local businesses and schools to introduce manufacturing to the youth. Hastreiter, vice president at his family’s company, Hastreiter Industries, in Marshfield, Wisconsin, has recognized that not all the school districts in his community have a machining program and, if they do, none of them have CNC machines. So he is collaborating with Shiloh Bound (Hastreiter Industries’ 501(c)3 nonprofit), 10 local school districts, two local

Kylan Hastreiter, whose CNC machine shop is a 2018 Top Shops winner, has a goal to impact communities by providing people with maximum opportunity to learn about manufacturing through investment and partnerships through education. Photo credit: Hastreiter Industries

colleges, the Marshfield Area Chamber of Commerce and Industry, and local businesses to launch C2 makerspace. C2, which stands for “collaborate and create,” will include CNC turning and tabletop five-axis mills, laser cutters, 3D printers and much more equipment for use by students in grades 5 through 12.

The makerspace Hastreiter spearheaded is scheduled to open in December this year. It is designed for students to learn and explore manufacturing by giving them an opportunity to create projects using technology that they may not have access to at school. It will support extracurricular activities such as robotic clubs and will supplement rural school districts’ technical education departments that cannot afford the cost of CNC equipment.

“C2 is primarily focused on teaching manufacturing, engineering and electronics,” Hastreiter says. “It’s not about our company; it’s about our local industry and ensuring our young people have exposure to it. A student can’t go into a field if they don’t know it exists.”

This mentor (left) is working with an apprentice at Hastreiter Industries. Kylan Hastreiter explains how important it is to build relationships with local tech schools to gain apprentices as well as to learn about what instructors are teaching in class and helping them understand what skills are critical to teach.

Photo credit: Hastreiter Industries

Hastreiter is also on advisory committees for three local schools, which keeps him informed about what the schools’ machining programs are teaching and enables him to offer his expertise to them when necessary.

To aid in the funding of local technical education programs, he has also established three yearly scholarships that benefit students as well as the schools where they attended machining classes. For example, one student who is passionate about manufacturing may win $1,500 to put toward higher education and, at the same time, their school’s technical education program will also receive $1,500 from Hastreiter Industries.

Hiring Inexperienced Operators

Because of the skilled worker shortage, some of this year’s Emerging Leaders are implementing workforce development strategies that are more focused on hiring inexperienced machine operators than experienced ones in order to train them to eventually move on to become skilled machinists.

Emerging Leader Mike P. Reader (left) with his nominator, father and president of Precision Plus, Mike J. Reader, says building relationships with contacts outside of his company has helped him grow as a young leader in the industry and in his business. “If it weren’t for our PMPA (Precision Machined Products Association) membership, I wouldn’t have been able to travel to conferences and social events where I’ve met other industry contacts like me and learned from their stories and their failures.” Photo credit: Precision Plus Inc.

According to Emerging Leader Mike P. Reader, who is vice president of engineering at Precision Plus Inc. (Elkhorn, Wisconsin), his company often chooses to employ inexperienced operators because they keep a fresh set of eyes on the processes. He explains that the young or less-knowledgeable operators do not come to work with bad habits ingrained or a “we’ve always done it that way” mentality.

Precision Plus, a provider of machined components with Swiss CNC capabilities, naturally hires a greener workforce because of its successful apprenticeship program which currently includes 10 students. The program enables apprentices to graduate from the apprenticeship and immediately begin a full-time job at the company.

Stefan Brusky (far right), director of education and business development at Precision Plus, is leading a hands-on lesson with a couple of the company’s youth apprentices. Mike P. Reader and Brusky work together to provide the best possible experience for engineering and production interns as well as youth apprentices. Photo credit: Precision Plus Inc.

Reader, who manages the internship program, finds it gratifying to witness an inexperienced employee who has never seen a machine tool before entering Precision Plus learn the details of manufacturing and find his or her passion on the shop floor. He intentionally offers a variety of experiences on the shop floor, and then helps each student realize what they gravitate to and what their strengths are.

Hiring the younger, inexperienced generation is also Alex Cheesman’s strategy. He is the president at a newly formed subsidiary of his parent’s company, called ICE (Innovative Custom Engineering) Tools, in Sussex,

Living in the manufacturing world for as long as he can remember, 21-year-old Alex Cheesman has not only begun a new branch of his family’s company that designs and manufactures cutting tools but is also working on two tooling patents. He has a degree in Robotics and has completed self-taught courses in manufacturing engineering. Photo credit: ICE Tools

Wisconsin. From his experience, young employees have been more enthusiastic about learning and are more concerned about being a part of a team than about the amount of money on their paycheck. He also says he has been challenged by the older generation not sharing their knowledge with the new operators. Therefore, as much as Cheesman would like to hire an experienced machinist, he believes it is worth the time to hire someone fresh out of high school who is willing to learn and grow with the company.

With only three machinists currently, including himself, Cheesman hopes to retain his one young employee and eventually attract more who are willing to stay with his company. To do that, he will strive to change their responsibilities daily, so they do not get bored with the monotony of working on one machine or one process all day long, he explains.

In-House Training

Shopfloor training programs, either ongoing for all operators or for new hires, are most effective when thoughtfully executed based on operators’ skill levels. While sending operators outside the shop for training can be helpful, it does not offer a tailored learning experience. In-house training can be catered to an operator’s specific needs within a specific shop.

Emerging Leader Jesse Ziegler has developed an in-house weekly training program for less-skilled machinists at Swissturn/USA (Oxford, Massachusetts), where he is manufacturing manager. Ziegler strives to set up each machinist for success, so he feels strongly about providing thorough training where they learn more than only the basics.

Although training operators is his passion, Jesse Ziegler also focuses on continuous improvement in the equipment side of the business as well. He keeps the machine shop updated with new machines and technologies to keep the company competitive. Photo credit: Swissturn/USA Inc.

During the training that he says is laid back and unstructured, he questions them about the challenges they are facing that week, and, if necessary, Ziegler recreates the problems they describe on the equipment and teaches them how to troubleshoot each one. Although he does not use a book, he sometimes finds additional information to explain troubleshooting and prints it out for the operators to refer to later.

He also uses a portion of the training for employees to talk about whatever is on their minds and urges them to ask any questions about the equipment or processes they are working on. He makes himself available for one-on-one conversations as well.

Machinists Are an Asset

A machine shop can have the best precision machining equipment, but without skilled employees, machines sit idle. Emerging Leader Vinny

Vinny Campellone, who opened his CNC machine shop right before the COVID-19 pandemic began in early 2020. The new shop survived, in part, by winning jobs that the bigger machine shops that were forced to shut down had to reject, giving his small business a chance instead. Photo credit: PenCo Precision

Campellone, CEO of PenCo Precision LLC (Wilmington, North Carolina), understands that concept well and realizes that well-trained machinists are hard to come by. His strategy is to recruit employees, treat them well and let them “do their thing.” That “thing” he describes is the talent that will help the business succeed. “I think our business should be centered around our machinists just as much as the equipment,” he explains.

Echoing a similar sentiment is Emerging Leader Britany Dittmer, production manager at Alco Manufacturing in Elyria, Ohio. She says operators on the shop floor know best and therefore she treats them with esteem and often asks their opinion about processes and practices. She says she likes to give the operators prompts to help initiate the thought process and freedom on how to achieve their given goals on their own.

Beginning her career at Alco in 2016 as a line inspector with no industry experience, Britany Dittmer recognized the need for a more structured written training program after only a month at the company. She took the initiative to develop a job-specific program to train new hires using a process-targeted approach. The course was the catalyst for the development of Alco’s technical training program, which is now used for machine operators as well as quality inspectors. Photo credit: Alco Manufacturing

Dittmer helped launch an incentive program for Alco’s operators that involved decreasing their work hours. Prior to offering the incentive, the operators were working Monday through Friday with optional Saturdays from 6 a.m. to 4:30 p.m. and the second shift scheduled from 5 p.m. to 3:30 a.m. Once an operator reaches his goal, he is dismissed on Friday before 11 a.m., and no Saturday overtime is required. Although they are working less, the operators still get paid for their regular hours.

She says this incentive created communication among the operators and their departments about how to reach these goals. After implementing the incentive program and the operators working jointly to achieve their goals, the company increased throughput by 20%. Dittmer says this plan has also decreased the company’s labor costs and has improved operator morale.

Lean Manufacturing

Emerging Leader Allison Heil has a vision for how manufacturers can run smooth operations and sustainably implement lean manufacturing. She does this by leading all aspects of manufacturers’ life cycles and helping manufacturers get the most out of their shopfloor data. She is the head of

Through training, data analysis and successful product implementation, Heil, in her first 12 months with Amper Technologies, helped the company’s U.S. manufacturing customers save more than $15 million. Heil earned her Six Sigma Black Belt while working as a manufacturing engineer at a previous company.

customer success at Amper Technologies — creators of an overall equipment effectiveness tracking and analytics tool. Heil is responsible for building customer training programs, implementing best practices and influencing new product features, as well as serving as the main point of contact for all Amper customers.

Although lean can be an effective continuous improvement tool, it is not useful for every facility, Heil explains. She says it works in machine shop cultures that already have data reporting in place and a culture of respect; not in operations where there are no systems set up to be able to sustain the diligence necessary for lean manufacturing to be successful. She explains that to be prepared to implement lean, shops must have good training programs and a solid foundation first.

Allison Heil often uses lean manufacturing to help customers with organization. One lean technique is to reduce wasteful time and motion. To do that, shops can ensure that all items are organized and each item has a designated place. Photo credit: Amper Technologies

Heil explains that lean is a structured continuous improvement approach that needs to be a top-down driven initiative. Lean empowers people to build the right system for them from the bottom up.

Not only is it necessary to have a champion driving the project and creating goals but it’s also just as important to have a project owner involved who is not as busy as the high-level champion. The project owner is hands-on with the project and tracks the project.

“As long as you have these personnel layers in place, and the right goals and communication, it’s going to get done,” Heil explains regarding lean manufacturing programs.

Tricks of the Trade, Continued

Our Emerging Leaders had even more to say about how they manage their businesses and influence their companies from wherever they sit. They have something to say about the importance of networking, an “only accepting orders that you can fill” philosophy, establishing an effective performance review process, reducing inventory and more.

Dittmer’s leadership qualities also shined as she shepherded training of Alco Manufacturing’s new ERP system, of which she quickly became proficient. She also developed software best practices for the system. Photo credit: Alco Manufacturing

Reduce work-in-process inventory: Restructuring Alco’s parts washing room – going from nine washers down to five – and making it a more functional department is how Dittmer reduced work-in-process inventory by 50%. “Focusing on the movement, steps and flow of the department, and reducing the time it takes to do those things was key,” she says. She adds that the transformation of the cleaning department took the company from being 24 to 48 hours behind in processing to processing in real-time.

Focus on keeping current customers satisfied: So that PenCo does not get behind in its customers’ order processing, Campellone says he has learned not to accept jobs that his small company cannot complete on time. Instead, he focuses on the customers he already has and keeping them happy. He turns down expedited fees and some new orders because he said he would

This apprentice is working with a machinist at PenCo Precision. Campellone and his growing team have ambitious expansion goals. His mission statement is, "To provide customers with the highest quality products in a timely manner, but to do it in a cost-effective way. We strive to understand the customers’ processes and the challenges that come with them. Helping bring to life our customers' designs and visions is the goal in any of our customer relationships." Photo credit: PenCo Precision LLC

rather be upfront with prospective customers, which he hopes will eventually pay off. “As we grow, I will add new customers when we can, but for now we will take good care of our current customers,” he explains.

Effective performance reviews: Establishing performance reviews that satisfy the employees’ and employer’s needs is critical to ensuring positive morale in the workplace as well as productivity. Ziegler recently revised the biyearly performance review process at Swissturn/USA and has received a positive response from employees.

First, employees fill out a self-review where they can voice their opinions and grade themselves regarding their performance. Next, Ziegler reads the self-review and rates the employees based on his thoughts and the employees’ work performance. He then sets up a coffee meeting with each person to converse with each person about how they can improve and what they are doing well. Then, the next review is tied to a salary review and a possible pay increase if the employee is deserving.

Because the education and training of his employees are on top of his priority list, Ziegler has spearheaded partnering with a local college to develop a 12-week training program on business and personal finance that is offered to every Swissturn/USA employee. “I feel it’s important that everybody understands the financial side of things,” he adds.

RELATED CONTENT

-

Lean Means Being Comfortable

Like writing, lean manufacturing requires people to be comfortable in their own skin while checking any ego issues at the door.

-

Putting your Shop on a Diet: How to Become Lean

There are strategies involved in achieving lean for a shop, but like going on a diet, lean doesn’t happen overnight and it takes some work on your part to get your shop in shape.

-

Let Them Move the Table

Empower your employees to make a lot of little changes and improvements to make their job in your machine shop easier. Small increments of improved efficiency add up quickly.