Helpful, Free CAD Model for Those Who Machine DOM Tubing

This machine shop 3D prints a plastic plug that it inserts into the end of tubing to prevent chips and coolant from entering the lathe's bar feeder. It offers a free CAD model of it for other shops machining that material.

#horizontal-and-vertical-lathes

Contact Superior Metal Products to receive a free CAD model of the plug that it 3D prints for machining tubing. (Photo credits: Superior Metal Products)

Superior Metal Products’ 3D printing capability isn’t a profit center. But, it has served the Omaha, Nebraska, CNC machine shop well in other ways.

While writing for Modern Machine Shop, I visited Superior Metal Products to develop this story about a neat robotic machining cell the shop had installed to eliminate manual loading of a family of cast plates, a process that was unpopular among employees. While there, Frank O’Conner, company president, showed the various ways his operation has used its Lulzbot desktop 3D printer to make items such as toolholder trays for the machines in that cell as well as workplace organization items attached to the cell’s fencing to hold Allen wrenches, a broom, a dust pan, a cleaning bottle, a grease gun, job travelers and so on.

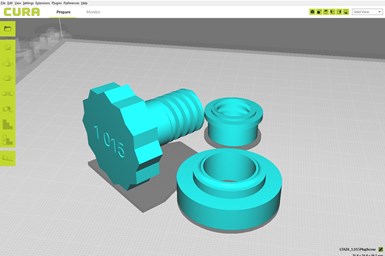

All three plug components are printed at the same time.

A plug used when machining drawn over mandrel (DOM) tubing to prevent chips and coolant from shooting back through the tube and into the bar feeder is another unique item the shop prints. O’Conner says the shop struggled to find a solution that offered push-point consistency for the bar feeder and positive sealing for the various tube inside diameters it ran. Tapered plugs often dislodged and/or leaked. And, the plug ends might not be installed perpendicular to the tube, meaning push rod droop or tube orientation can cause push length variation.

The CAD model can be scaled to suit a variety of different tube inside diameters. The size of the plug is shown on the face of the knob.

The plug features a 3D-printed threaded knob, expander and nut that are all printed at the same time. An appropriately sized O-ring is also required. Once inserted into the end of a bar and tightened, the plug provides an effective seal and consistent push point that is perpendicular to the tube. The shop has a base plug design and simply modifies the sealing diameters depending on the tube ID and prints. It’s not a problem if a plug gets lost. 3D printing replacements is not costly.

O’Conner now offers to send other shops a free CAD model of the plug so they can scale or modify as needed, then print for themselves. If interested, reach out to Superior Metal Products by calling 402-895-9619 or emailing sales@superiormetalinc.com.

RELATED CONTENT

-

Optimize Minimum Quantity Lubrication Control Through a CNC Program

Minimum quantity lubrication (MQL) on a lathe offers many benefits when implemented properly. MQL becomes more of an asset when lubricant and air delivery can be controlled from a CNC program.

-

Video Series Demonstrates Gun Part Manufacturing

Videos show various firearms cut with high-speed precision on Okuma machining centers and a horizontal lathe.

-

Video: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.