Video Series Demonstrates Gun Part Manufacturing

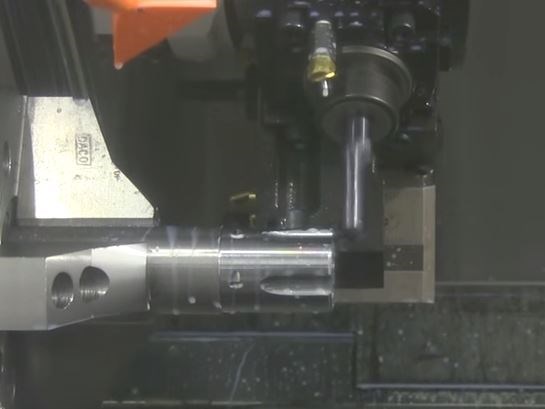

Videos show various firearms cut with high-speed precision on Okuma machining centers and a horizontal lathe.

#horizontal-and-vertical-lathes

Okuma’s new video series demonstrates CNC machines used in gun part manufacturing, spotlighting high-speed, precision cutting, live tooling, milling and drilling. Okuma’s gun part manufacturing video series includes:

- Rifle Stock Mold: Okuma’s five-axis MU-500VII vertical machining center cuts a custom-designed rifle stock mold

- AR15 Upper: An MB-4000H horizontal machining center machines an AR15 upper

- Gun Barrel Extension: Cut on an Okuma LB3000-EXII horizontal lathe, the machining of this gun barrel extension uses a variety of cutting tools and operations

- Commemorative Plaque: Using a GENOS M460-VE, this video shows the CNC milling of a gun shaped plaque for a firearms event

- 1911 Trigger Housing: Machining of a 1911 trigger housing, using an Okuma MB-56V vertical machining center equipped with a Lyndex Nikken rotary table

- Gun Cylinder: A .50 caliber revolver cylinder is cut on an Okuma LT3000 EX, 3 turret horizontal lathe

(Special Note: Some videos are filmed without the use of coolant, to better show the cutting capabilities of the machine, without visual interference. CNC machine operation without coolant is not recommended.)

To see Okuma’s gun part manufacturing video series, click here.

RELATED CONTENT

-

PMTS 2021 Product Preview: CNC Turning Centers and Swiss-Types

Learn about some of the new CNC turning centers and Swiss-Type lathes to be displayed at PMTS 2021.

-

Helpful, Free CAD Model for Those Who Machine DOM Tubing

This machine shop 3D prints a plastic plug that it inserts into the end of tubing to prevent chips and coolant from entering the lathe's bar feeder. It offers a free CAD model of it for other shops machining that material.

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.