on a CNC lathe, and how to set it up. Video credit: Unist Inc.

Having as much control as possible over machining processes is what most machinists strive for. The amount and application of coolant delivered during the chip-making process on a lathe should be no exception. For direct control over minimum quantity lubrication (MQL) output, Unist Inc. offers an MQL system that communicates directly with a machine’s computer numerical control (CNC) to enable operators to specify lubrication parameters by inputting codes in a part program. The company’s Quantum digitally controlled lubricator is designed to optimize MQL flow rates for each machining operation on a single machine tool because flow rates are visible and editable. Therefore, operators can fine-tune each operation for the best results.

But why MQL? Although it is still more likely to be used in Europe, why are more U.S. shops starting to adopt this technology as an alternative to conventional flood coolant delivery? One reason is more is not always better. MQL delivers a very small amount of lubricant to a cutter’s edge in the form of an oil mist or aerosol, as opposed to traditional techniques of flooding the workpiece and tool with a substantial volume of liquid coolant. Unlike cutting with flood coolant, only a tiny bit of that aerosol is left on the chips, workpiece and machine during the cutting operation.

Featured Content

Although flood coolant is still the most widely used method of cooling and lubricating machining processes across the globe, other advantages of MQL technology are clear and sizable, the company says. Shops that have implemented MQL can experience the following environmental, enterprise and economic benefits.

- Environmental: Quality MQL oils are nontoxic and biodegradable. Bacteria do not grow in oils, so no biocides are needed. Beyond that, the process uses less than 1/10,000 the amount of fluid as it does flood coolant, and there is nothing to be disposed of or recycled. Recyclers and pumps are not needed, which reduces energy consumption. In comparison with flood coolant, MQL’s environmental footprint is virtually invisible.

- Enterprise: Shop floors stay cleaner (and safer), and equipment is not coated with coolant when MQL is implemented. Using high-quality lubricant and the correct amount, the cutting process leaves behind a quality surface finish. And, because of reduced thermal shock, tool life increases. Shopfloor employees usually realize the added benefit of fewer skin irritation issues related to interacting with metalworking fluids, and they do not have to breathe in the coolant and its additives.

- Economic: While the price per ounce of MQL oils can be significantly higher than general flood coolants, the overall price of the fluid per part is usually less because so much less is used. When combined with the savings from other areas (such as improved tool life, elimination of equipment that maintains the fluids, and energy savings), MQL can have a positive impact on a shop’s bottom line.

Full MQL Control and Monitoring

MQL advantages are magnified when adding the ability to interface directly with a machine’s CNC, a programmable logic controller (PLC) or a built-in interface, especially when a part being machined requires multiple

The Quantum provides users the freedom to program MQL delivery according to each operation’s needs. Photo credits: Unist Inc.

operations. Each machining operation is often best suited with a different MQL flow rate, not limiting itself to preprogrammed rates or one fixed manually adjusted rate. The Quantum MQL system provides users the freedom to program MQL according to each operation’s needs.

To provide uniform and precise lubricant delivery, the MQL system for lathes keeps the air and oil lines separate, as far as possible, until they mix at the machine’s turret. This dual-channel delivery system is designed as a hose within a hose; the inner hose delivers the oil and the outer hose delivers the air. Keeping these lines separate maintains a consistent atomization of fluid. This prevents fluid collection on the outer walls of the hose, which potentially causes spitting or dripping lubricant, which does not produce a smooth spray.

Also, implementing a change to the proportion of oil and air within the delivery system is less problematic when using a dual-channel system. Changes are instant when using this method, and there is no mixture inside the hose that needs to be expelled prior to making changes.

“Whether it is roughing, finishing, threading or some other operation, you have full control over turning on and off the rate of air and oil,” says Tim Bangma, product manager at Unist Inc., about the Quantum.

After determining the correct amount of lubricant and flow rate for each machining process, the machinist inserts commands into the

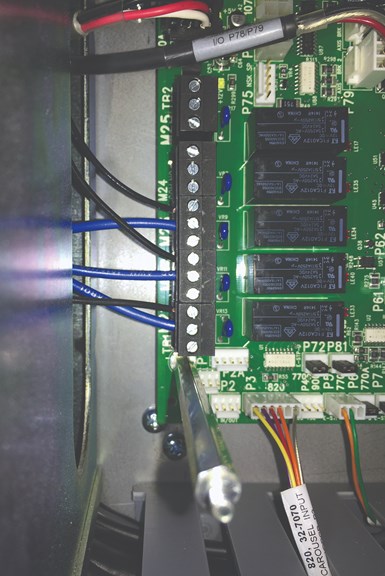

The Quantum is connected to a machine tool with either discrete or serial interfaces.

part program.

The Quantum offers control of as many as six lubricant outputs and can use as little as a fraction of an ounce of lubricant per hour. Plus, the system can supply either a lubricant aerosol, straight fluid or air only to each operation.

Along with delivering precise accuracy for MQL application, this system also provides monitoring capabilities for low levels of fluid and air as well as fluid flow. The built-in monitoring system in the Quantum pauses the machine that it is monitoring if it is experiencing one of these problems and flashes an alarm to alert the operator of the issue.

“The Quantum system’s positive displacement pumps can be equipped with flow sensors that confirm fluid is delivered when the pumps are cycled,” Bangma explains.

Lubricator Installation

The Quantum is connected to a machine tool with either discrete or serial interfaces. Although the Quantum installation on a CNC lathe is a straightforward process, according to Unist, some machine shops are more comfortable with a

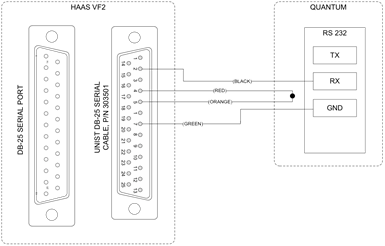

This serial connection schematic illustrates how the Quantum is connected to a Haas VF2 machining center. However, this provides basic guidance for any system.

Unist representative visiting their locations to install the applicator. However, there is an equal number of shops that feel comfortable completing the process themselves.

Regardless of who completes the installation, the process primarily consists of five parts when done properly:

- Mounting the lubricator on or near the machine. Finding an area that is convenient for refilling the reservoir is ideal.

- Removing machine guarding and locating existing flood coolant lines that feed the through-turret tool. The MQL tubing should be routed through the machine and connected to the turret at the point where the flood coolant enters the turret.

- Connecting compressed air to the inlet of the lubricator.

- Connecting power and control signals to the applicator from the machine control cabinet using machine instruction documents. The appropriate terminals can be located.

- Installing nozzles on each turret tool station with a variety of tools that can be installed on a CNC lathe.

Once the system is fully installed, proper nozzle positioning is also critical to ensure a successful MQL application. “You can have the most accurate pumping and delivery system, but if the nozzle isn’t aimed properly, it can be a big problem,” Bangma says.

Also, because some mist might be generated from the MQL process, it could be necessary to install a mist collector on the machine.

A Word About Lubricants

Using a high quality lubricant for MQL is critical to adhere to the surface of the tool and provide a thin, low-friction barrier between the cutting tool and workpiece. Unist says its Coolube, for example, not only contains polar properties that create a strong, consistent bond between the lubricant and metallic surfaces, but also is bio-based, making it environmentally friendly and safe for operators’ skin.

“Coolube is highly refined, free from a lot of impurities and additives,” Bangma explains. “It’ll keep on a shelf for a very long time.”

Unist Inc. | 800-253-5462 | unist.com

RELATED CONTENT

-

Heat’s Impact on Parts Cleaning

Thermal dynamics is important for assisting in the cleaning of a part. Adding heat or energy influences the cleaning process through its impact on chemistry, the water within the washer and its effect on drying.

-

Getting Ready for Lights-Out Manufacturing

Lights-out manufacturing has the potential to save money while increasing capacity, but shops need the right equipment and to address potential challenges before implementing it.

-

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.