Swiss-Types Offer Advantages Beyond Watchmaking

CNC sliding headstock lathes are becoming more popular among traditional machine shops for their multitasking capabilities, some offering B-axis milling spindles.

Bar-fed CNC Swiss-type lathes are the computer-controlled evolution of cam-actuated screw machines. One common application of these versatile, sliding headstock machines was machining intricate watch components. Today, though, they are being used to produce a much more diverse array of parts for various industries.

It’s the sliding headstock that separates Swiss-types from conventional lathes. With this, barstock is gripped by a collet and fed through a guide bushing and past a stationary turning tool. The guide bushing provides support at the point of the cut making Swiss-types well-suited for parts with high length-to-diameter ratios such as medical bone screws. The video below shows a variety of operations used to machine a dental implant component complete on a Tornos EvoDeco 16 Swiss-type as well as the action of the sliding headstock design.

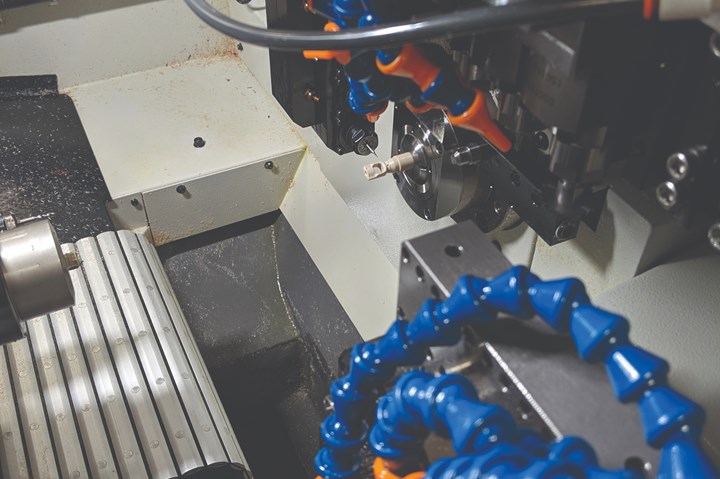

Swiss-types with a B-axis milling spindle essentially become a five-axis turn-mill with the bonus of a sliding headstock. The sliding-headstock is what enables the machine to effectively turn long parts with small-diameters, while the B-axis milling spindle can approach workpieces in the machine’s main or subspindle at a variety of angles. This makes it possible to eliminate secondary operations by machining parts complete.

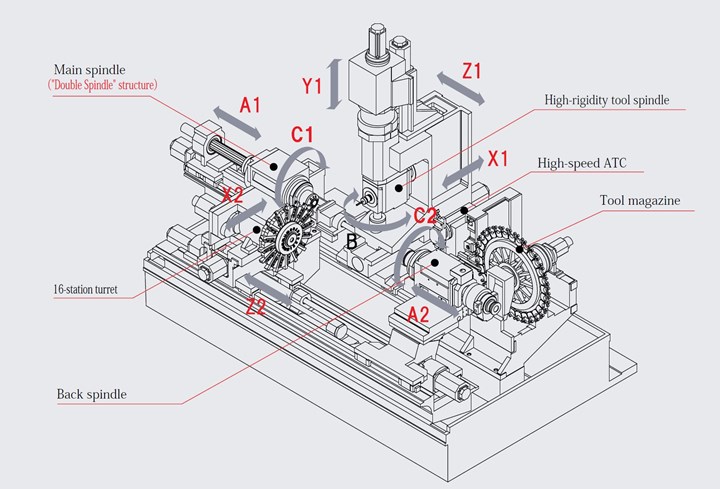

This drawing shows a Tsugami TMU1 machine’s primary components and locations of its nine axes. The subspindle enables back working to be performed to machine parts complete. (Image courtesy of REM Sales.)

Some builders offer automatic tool changers for their B-axis Swiss-types. This is seen in the image above showing the main components of a Tsugami TMU1 machine. Marubeni Citizen-Cincom also offers a toolchanger for its L20XII ATC Swiss-types shown in the video below. Tools mount on the gang tool post and can accommodate 13 front-machining B-axis tools (12 of which are stored in the ATC). The ATC tools can be used in conjunction with existing turning tools and cross machining rotary tools. They can be preset offline for fast setups while enabling the complete machining of complex geometry as is common to medical implants.

For deep thread forms such as ACME, thread whirling attachments can be effective. Unlike single-point threading, thread whirling units have multiple cutting inserts mounted inside a rotating ring. The thread whirling ring rotates around a cylindrical component to cut the thread in one pass. In the animation below showing a double-thread screw being machined, thread Whirling and turning are performed simultaneously using a Horn attachment saving time and reducing the material volume which has to be removed by the whirling inserts.

But, any screw that is produced in a Swiss-type needs some sort of a drive feature machined in the screw head. With rotary broaching, it’s possible to cut and shape the drive feature into the screw head while the spindle is rotating as demonstrated below. This is well-suited for complex features that would be challenging to machine using small end mills.

A recent development for Swiss-types is the addition of programmable lasers for cutting, welding and engraving. In addition to creating small holes, a laser can generate slots, spirals, helical shapes, widows and other complex shapes. Unlike conventional machining, there are no issues with wear, cutting forces or burrs. Laser machining is commonly used on tube material for medical applications.

Another aspect of some Swiss-types that can be considered a multitasking feature is those that can run without the guide bushing and function as a chucker-style lathe (oftentimes referred to as “convertibles”). The flexibility of a convertible guide bushing opens the machine up for a larger variety of workpieces since many parts run on these machines do not meet the length-to-diameter ratios that define traditional Swiss parts. Instead, setting the guide bushing for blanks or barstock that don’t need the guide bushing, job changes over can be reduced by simply removing the guide bushing and programming the Z-axis stroke to extend further into the cutting zone.