There can be economic advantages using a chucker lathe to machine parts from shaped blanks created by processes such as casting, forging and metal injection molding (MIM). The goal of this concept using near-net-shape components is to limit the amount of roughing operations and finish the part with precise turning. The benefits are multiplied with a production turning platform such as a multi-spindle lathe.

Tornos, for example, has built custom CNC multi-spindle chucker machines to meet customers’ specific demands. The company now offers two standard models: the MultiSwiss 6x16 Chucker and the MultiSwiss 6x32 Chucker that are based on the traditional bar-fed models.

Featured Content

With the MultiSwiss 6x16 Chucker, a part blank is loaded into the machine’s workzone pneumatically in a device that turns it 90 degrees in front of position five’s spindle. The spindle then picks up the part and machining starts in a clockwise direction (positions five, four, three, two and one), after which the part is extracted by the counter spindle and delivered into a vibratory bowl outside of the machine.

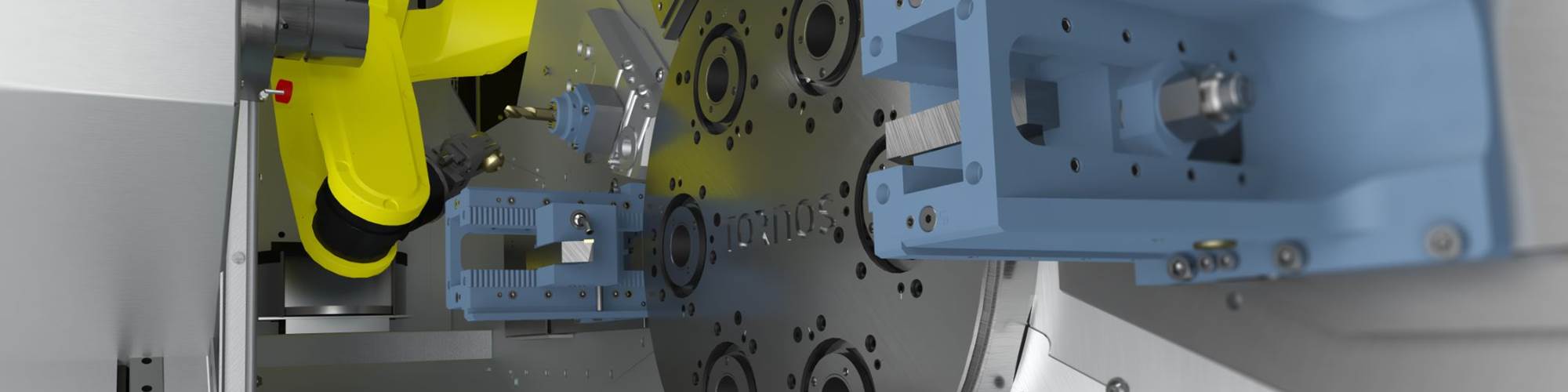

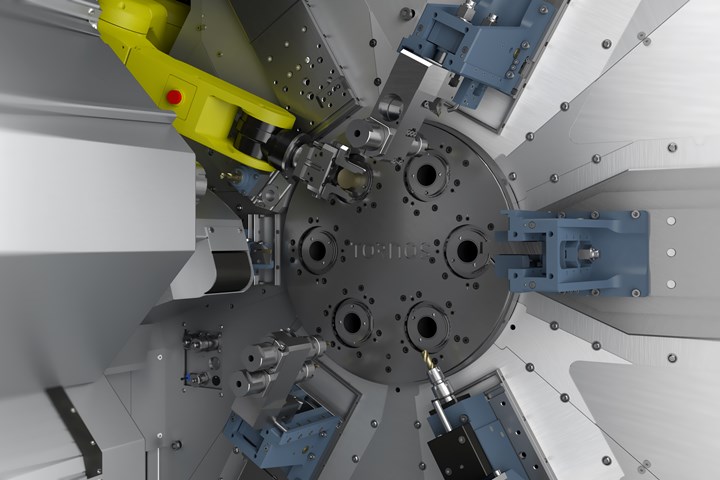

This multi-spindle chucker features a robot inside its workzone to load workpiece blanks. Photo credits: Tornos

Similarly, the MultiSwiss 6x32 Chucker features the same kinematics as the MultiSwiss 6x32, offering six spindles, up to three Y axes and four tools for backworking operations. It is said to offer three key benefits:

- A new spindle design that enables the use of various clamping systems for push pliers, pull pliers or chucks. That means parts bigger than 32 mm can be gripped.

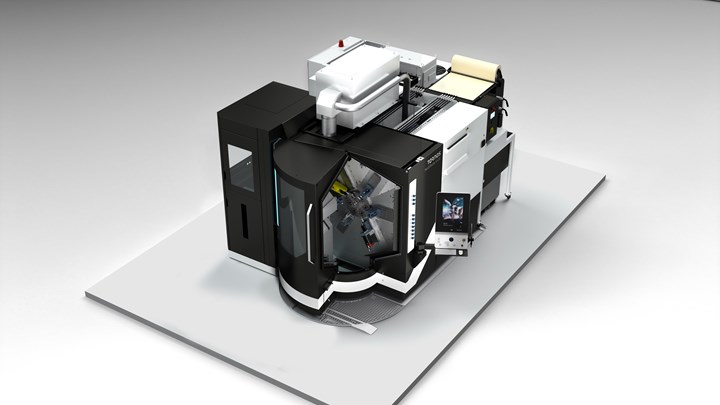

- A new, more compact machine body that conserves floor space and enable integration of through-spindle coolant.

- A robot solution that is integrated in the machine for loading/unloading parts via a small carousel that separates the machining area from the palletizing cell. This modular solution is designed to accommodate the users’ needs, depending on the parts to be machined or operations to be performed. Single or double gripper unloading by robot or standard unloading with a ramp are said to be easily accommodated.

Using near-net-shape components limits the amount of roughing operations.

For the main spindles and counter spindle, a collet system is used to clamp blanks up to 32 mm in diameter (length to diameter ratio of 4:1). Alternately, a chuck system can be used for bigger parts up 50 mm in diameter and 50 mm long. Depending on the part’s mechanical sensitivity, force adjustment is possible. The spindles have an internal, fixed stop. Mechanical adjustments are not required as all spindles are controlled by independent axes that can be numerically offset through a parameter table. In addition, low- or high-pressure flushing is available during machining as well as part loading/unloading.

Multi-spindle chuckers take up less floor space because they have no bar feeder.

Part unloading can be done through the counter spindle as with a regular MultiSwiss machine. It can also be done using a robot either out of the main spindle (when no backworking is required) or from the counter spindle (if the user prefers part palletization). For robotic unloading and palletization of the part, a swivel carousel is used that separates the working area and the palletizing cell. A second robot then loads and unloads parts from the swivel carousel, making for a faster, cleaner solution, the company says. Depending on cycle time, a double gripper on the robot can be used to increase loading/unloading speed.

External handling is made possible by Tornos’ turnkey palletizing cell, a two-by-eight pallet system or a 16-pallet system (600 mm by 400 mm). For bulk parts, a simpler system can be used: The robot can be fed with a bowl feeder and a regular part extraction solution can be used. Part cleaning and measuring can also be integrated.

A chucking machine’s compactness — made possible in part because there’s no need for a bar feeder — means users can benefit from a range of peripherals to achieve greater flexibility and autonomy. Standard machine features include a swarf management system and an oil tank high-pressure pump with dual filtration and a chiller. In addition, the machines can be reconverted to a bar turning machine with bar feeder, if necessary.

RELATED CONTENT

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

-

The Evolution of the Y Axis on Turn-Mill Machines

Introduced to the turn-mill machine tool design in about 1996, the Y axis was first used on a single-spindle, mill-turn lathe with a subspindle. The idea of a Y axis on a CNC originated from the quality limitation of polar interpolation and the difficulty in programming, not from electronic advances in controls or servomotor technology as one might commonly think.