It’s time to reunite at the precision machining industry at the Precision Machining Technology Show (PMTS) 2023 set for April 18-20, 2023, in Cleveland, Ohio, at the Huntington Convention Center. It’s a great time to consider planning and investing for possible updates in your company’s technology, automation and software to make your business more efficient and productive.

Production Machining wants to help kick off your research with a series of PMTS Product Previews. In this group, we’re taking a look at toolholders, including a quick-change Swiss tooling system focused on rigidity and repeatability; carbide inserted toolholders for reducing downtime with fewer tool changes plus faster tool changeover; modular slide holders for multi-spindle screw machines; and more.

Before you go to the show, don’t miss PMTS show highlights in Derek Korn’s PMTS feature article and look for more PMTS Product Previews each week until the show! And don’t forget to register for the show.

For all the latest PMTS product highlights, please visit our extensive PMTS Preview Section which includes new PMTS products posted every weekday up through the show’s opening day.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining’s free monthly print magazine.

Click on each link below to read the full product post:

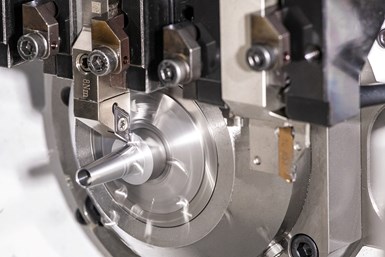

Iscar’s NeoSwiss modular quick-change toolholders line for Swiss-Type machines offers a variety of heads available for multiple machining operations, including turning, backturning, threading, grooving and parting. When developing the NeoSwiss line, Iscar focused on two main points: rigidity and repeatability. Changing heads can be done in seconds because of the rotary-wedge clamping mechanism.

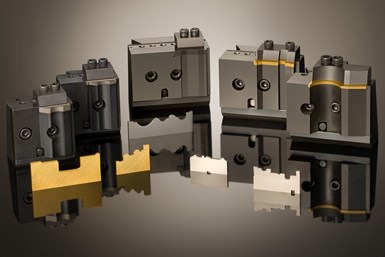

Photo Credit: Posa-Cut Corp.

Double-Datum Tooling from Posa-Cut are carbide inserted toolholders with interchangeable components making them well suited for short and long runs. They are said to reduce downtime with fewer tool changes plus faster tool changeover. The design accommodates both radial and axial differences between parts. A replaceable insert enables users to optimize geometries, grades and coatings, all designed for specific applications. Machine downtime for resharpening is eliminated.

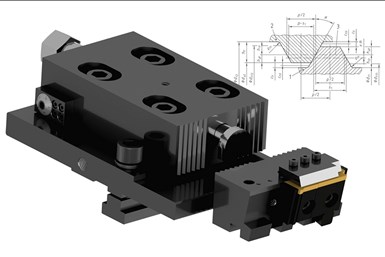

Photo Credit: Crowley Tool Co.

Crowley Tool’s Modular Slide Holders, with multispline interlocking technology, set the standard for rigidity and repeatability, the company says. The interlocking design yields accurate and solid lockup of the insert module to the slide holder. A working module can easily be changed in a few seconds by loosening a drawbar and exchanging it with a preset module from the workbench, with guaranteed 0.0005" repeatability.

Photo Credit: ETP Transmission

ETP Transmission’s Hydro-Fix Swiss is a hydraulic, high-precision clamping sleeve for Swiss-type lathes. The company says it is well suited for static front and back drilling operations, offering an improved surface quality as well as extended tool life. The clamping unit enables users to drill larger and much deeper holes versus ER collets or special deep hole attachments. Manufacturers can also use other holemaking tools such as boring bars, reamers, form tools and indexable tools — that often have larger shanks.

Photo Credit: Exsys Automation

Exsys Automation’s Preci-Flex modular toolholding system is said to reduce setup and tool change times for CNC turning centers to offer flexibility, precision and cost savings. This multifunction tool system features a single base holder and multiple tooling adapters, enabling shops to capitalizes on the ER collet pocket concept for a fast, accurate and cost-effective solution for lathe tooling changeovers.

Photo Credit: New Market Products

New Market Products’ (NMP) preset tooling system offers many features and benefits enabling customers to save time and reduce scrap. The bridge setup is the most advanced precision tooling available, enabling each tool to be independently adjusted without affecting other tools.The V7 Shave Holder offers quick-change presettable heads, precision diameter adjustment of .00025" per increment and built-in coolant ports to name a few of the many features. It is said the V7 Shave Holder also provides the best anti-chatter design available.

Landscape Source: Exsys Automation

RELATED CONTENT

-

This manufacturer finds value in modular workholding technology to speed production of toolholders and other components used in its automated surface finishing systems.

-

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

-

Production Machining showcases some of the latest toolholders, including technology from Goeltenbodt, Horn, GenSwiss, iSwiss, Iscar and Kaiser Tool.