Every month, we’re putting together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For October, we focused on toolholders — which are important for effective, safe connections between high-speed tools and machines. With the right toolholder, companies can safely and consistently produce quality, reliable products.

PM’s October toolholder showcase includes a pre-settable, quick-changeable tooling system for swiss-type lathes; a toolholder system that has clamping carried out via a clamping wedge on the face; a height-adjustable backworking holder offering precise coolant delivery; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s September’s Technology Review.

Click on each link below to read the full product post:

Photo Credit: Goeltenbodt

Goeltenbodt, represented in the U.S. by Schwanog, offers a pre-settable, quick-changeable and coolant fed tooling system for Swiss-type automatic lathes such as Tsugami, Star, Citizen, Tornos and others. The system is said to provide quick and easy tool changeovers and is pre-settable off the machine with repeatability of .0004″. Coolant-fed holders with high pressure ratings up to 1,500 psi are available.

Paul Horn GmbH offers users its Supermini toolholder system with face clamping as a set. With the Supermini holder variant, clamping is not carried out via the lateral surface of the cutting insert but rather via a clamping wedge on the face. This is said to result in a greater holding force on the insert and thus high rigidity of the entire system. Also, this style of clamping is said to increase repeatability when changing the insert and provide better utilization of the available space. This is said to be a great advantage on Swiss-type lathes, as the user can change the cutting insert without removing the toolholder.

GenSwiss’ GenQuick quick-change ER system for CNC Swiss machines and precision machining equipment has been redesigned to achieve faster setups and tool changes. It does this through the use of toolholder adapters and quick-change modules that can be preset and are based on the ER standard toolholding system. Base toolholder shanks are available from GenSwiss in diameters to suit most Swiss machine models’ ID working tool positions.

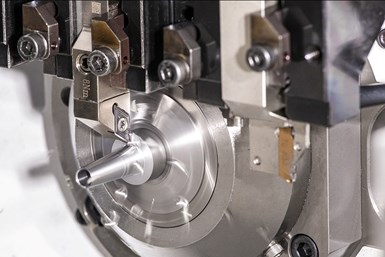

Photo Credit: iSwiss Corp.

The iSwiss Corp.’s Height Adjustable Backworking Holder X Type is said to offer precise coolant delivery to the cutting area up to 130 bars (1885 psi). It has been redesigned to point the coolant flow directly to the tip of the tool, which is designed to aid in evacuating the heat from the cutting area and breaking the chips. The system is built more rigidly to eliminate vibrations (up to 80%), which is said to help increase tool life and to achieve better surface finish. These holders are intended for Star, Citizen, Tornos, Mazak, Tsugami, Hanwha, Traub and Manurhin machines.

Iscar’s NEO Swiss modular quickchange tooling line for Swiss-Type machines are designed to provide rigidity and accuracy. The line is said to have a robust rotary wedge mechanical design for clamping rigidity. The company says rigidity is important due to the nature of the processes on Swiss machines and the difficult materials which are often machined, meaning that depths of cuts can be deep which can compound the need for an extremely rigid system. Accuracy is also essential when changing tools for part requirements and achieving seamless changeover from job to job. The repeatability of Iscar’s NEO Swiss tools is ±.0008” (±0.02 mm).

Photo Credit: Kaiser Tool Co.

Kaiser Tool Co.’ s Thinbit angled round toolholders are designed for CNC, conventional and endworking positions on Swiss screw machines. The angled round toolholders position the insert at 30-, 45- or 60-degree angles for reliefs, undercuts and angled outer diameter and face grooves. Round shank sizes are available in diameters of 1/2", 5/8", 3/4", 1", 20 mm and 25 mm. The angled round toolholders are for use with Thinbit inserts in grades for ferrous and nonferrous materials. Inserts are available in sizes 0.004" to 0.150" which come in 0.001" increments coated with TiN, TiAlN, TiCN, diamond film or uncoated.

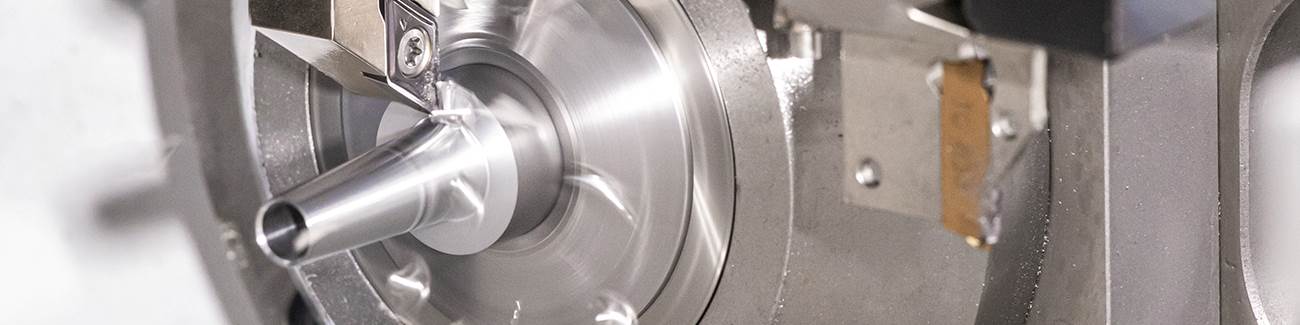

Landscape Source: Iscar’s NEO Swiss modular quickchange tooling line for Swiss-Type machines. Photo Credit: Iscar

RELATED CONTENT

-

This manufacturer finds value in modular workholding technology to speed production of toolholders and other components used in its automated surface finishing systems.

-

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

-

Learn about some of the latest toolholder solutions that will be on display at PMTS 2023.