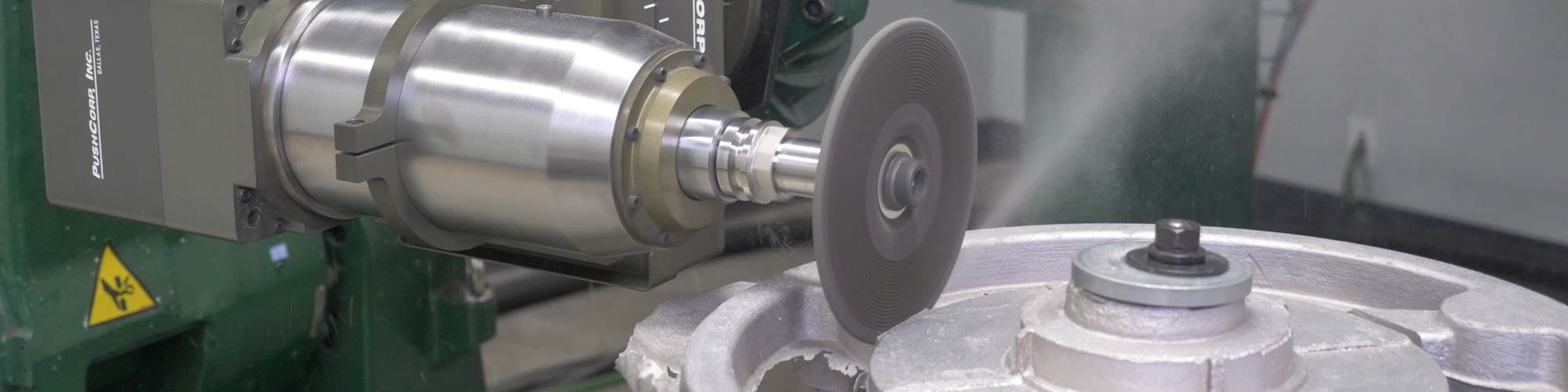

PushCorp offers a variety of BT30 and BT40 toolholders in various lengths, diameters and custom profiles that can accommodate many off-the-shelf abrasives. (Photo Credits: PushCorp)

As the use of robots and robotic processes has increased, numerous manufacturers have demanded more sophisticated ancillary capabilities. Increasingly, automated systems once designed to complete a portion of a manufacturing process are now incorporating multiple disciplines to deliver a completed or near-complete component or product.

One example is surface finishing. In earlier systems, parts that were welded or cut robotically required secondary operations that often involved manual grinding, sanding, deburring and/or other material removal processes. In the manufacture of devices and components requiring excellent surface finishes, such as surgical tools or implants, machined parts had to be moved to another system for polishing. In all cases, this presented a manufacturing bottleneck that hampered efficiency, drove up costs and too often resulted in scrap or inferior quality.

Featured Content

To provide a solution to these problems, PushCorp of Garland, Texas, a robotic tooling manufacturer specializing in material removal equipment, developed the Adjustable Force Device (AFD) in 1995. By sensing and delivering the amount of force required for a particular application, the AFD enables a robot to maintain a force that is both consistent and adjustable when in contact with a part’s surface.

In seeking applications, PushCorp noted the lack of rotary spindles capable of being mounted on the compliance device. In the late 1990s, most spindles were either designed for fixed automation applications (and were correspondingly very heavy) or pneumatic designs incapable of maintaining constant speed across the surface of the part.

By sensing and delivering the amount of force required for a particular application, PushCorp’s AFD technology enables a robot to maintain a force that is both consistent and adjustable when in contact with a part’s surface.

The solution was the development of the first PushCorp servo spindle in 1997. Incorporating a liquid-cooled permanent magnet, servo spindles possess the additional advantages of lower weight while delivering a high power-to-weight ratio and constant speed. This combination resulted in the ability to meet the challenges of an extensive variety of material removal applications, including grinding, sanding, deburring, polishing, weld shaving, drilling, routing, gate removal and cutting.

“Much of our initial experience was in the automotive industry where our equipment is used for a variety of processes during the body in white (BIW) stage before the car is painted,” notes Eddie Erlbacher, PushCorp senior product manager. “Since then, we have branched out to virtually any industry concerned with surface finishing, ranging from aerospace, where we have cleaned welds on rockets to deflashing injection-molded parts for children’s toys.

“Because surface finishing is such an extremely demanding process, we have always worked very closely with our customers,” he continues. “As a result, we have had to devise specialized solutions to meet their needs. This has resulted in a large and diverse product line. For instance, in addition to our active and passive force compliant devices, we offer a range of servo spindles, floor mounted belt and polishing stands, and robot mounted belt sander and weld ‘shaving’ equipment. As we’ve grown, we’ve realized that production of so many different product components demanded a machining strategy that enabled us to quickly change from one setup to another, while at the same time guaranteeing maximum repeatability. The solution we selected is the Hainbuch precision workholding system.”

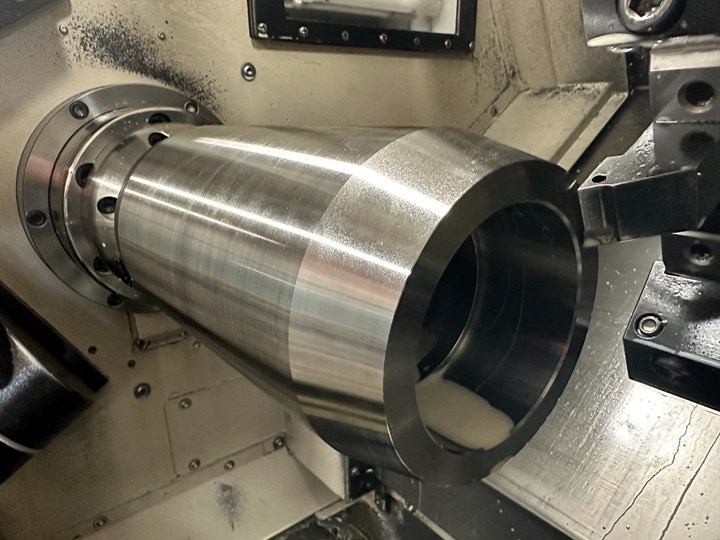

PushCorp's high-speed servo spindle housings, which require extremely tight tolerances, are turned on Okuma L250 turning centers.

Hainbuch manufactures a comprehensive line of precision workholding equipment in a wide variety of sizes primarily used for OD and ID turning applications. According to Michael Larson, director of marketing for Hainbuch America, “Our Spanntop and Toplus chucks are used in conjunction with clamping heads that can be quickly and easily loaded and unloaded. Toplus chucks feature a hexagonal receptacle for the clamping head, while the Spanntop models use a round clamping geometry. Both deliver significantly higher holding forces than conventional three-jaw chucks, as well as repeatability in the 0.015-mm range.

For internal part workholding applications, several styles of mandrels, marketed under the Hainbuch Mando name, are available.

Materials used at PushCorp include 6061 aluminum and 4140 steel, as well as a variety of stainless steels. Tolerances are tight, from ±0.003 inch, and batch sizes are typically small to medium (shafts are frequently run in lots of 60 pieces). Products generally range from 4 to 8 inches in diameter and lengths vary depending on the application.

“We’re constantly refining our product line in response to our customers,” Erlbacher explains. “For instance, manufacturers are trying to reduce footprint for better space utilization and, as a result, we are developing smaller, lighter weight tools that can be carried by a more compact robot.”

PushCorp uses two Okuma M560 vertical machining centers, both equipped with Hainbuch Manok stationary chucks, a lever-activated holding device compatible with clamping heads. “By using a Hainbuch Manok quick-change clamping device on our machining centers, we are able to remove a part in the clamping head from the lathe and quickly insert it into the Manok for machining without sacrificing repeatability,” says Matt Zielonko, PushCorp’s lead machinist.

Andrew Tisdale, South-Central Regional Sales Manager for Hainbuch America, notes that for turning applications, PushCorp uses an Okuma L250 slant-bed lathe equipped with a Hainbuch Spanntop 65 (65-mm size) pullback model. “The ability to draw the part against a solid stop creates real stability,” Zielonko notes.

The Hainbuch Manok is a stationary chuck that accepts clamping heads. This enables a part to be removed from a turning center and then secured on the machining center without sacrificing repeatability.

“The team at PushCorp takes a ‘hands-on’ approach that has enabled them to really make the best use of Hainbuch products,” Tisdale explains. “The company uses about 35 of our clamping heads, as well as two Mando mandrels sized to the ID applications.” These provide them with the ability to quickly change over to virtually any size range they need.

“We chose the Hainbuch system for its quick-change capability, its versatility, and its high-precision performance,” Zielonko notes. “It has cut our changeover time and really contributed to our profitability.

“As our machine shop has grown, our production philosophy has evolved. We’ve literally gone from huge chucks to the much more compact Hainbuch system that delivers more exacting performance. We have always been about quality rather than quantity, and Hainbuch’s commitment to efficiency and reliability has helped us to maintain that goal.”

Frank Burke is owner of marketing firm Burke & Towner Ltd.

RELATED CONTENT

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.