Have you ever wondered: “Is there a search engine for 3D models?” It seems there is. And, it can be valuable to machine shops and manufacturers as well as product designers.

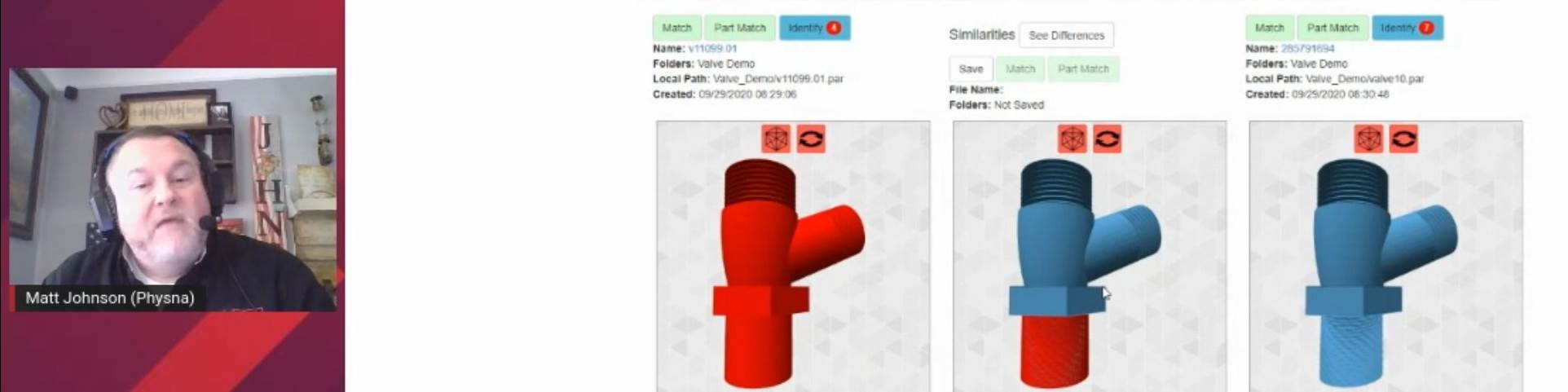

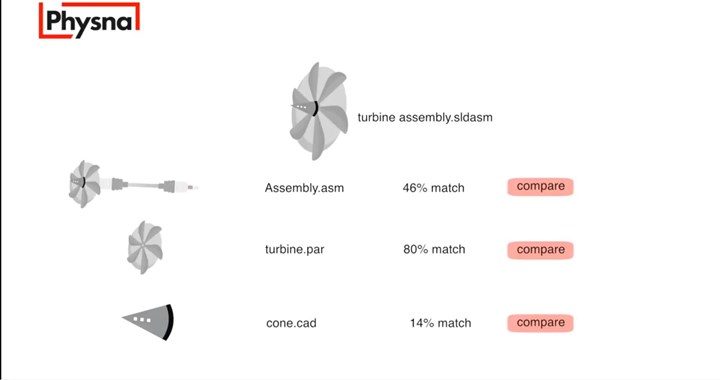

Cincinnati, Ohio’s Physna aims to bridge the gap between physical objects and digital code by analyzing CAD models and other 3D models to create a codified representation of a model — the “physical DNA” of that model. This digitized model enables Physna to show the detailed similarities and differences between models — even incomplete models or those with different file formats — as well as see all components in complex assemblies including parts contained in other parts.

Featured Content

In other words, it uses artificial intelligence to break down the structure of 3D models, analyzes them and determines how models are related to each other. The goal is to save engineering and product design teams many hours per person per year, reduce procurement costs, and enable anyone to immediately recognize parts and how they can be used.

But, machining operations can also benefit through faster quoting and tooling creation.

Physna uses artificial intelligence to break down the structure of 3D models, analyzes them and determines how models are related to each other.

Because it is challenging to capture and describe all the aspects of this technology in an article, I had the following discussion with Matt Johnson, Physna application engineer, who not only explained its value but also provided a demonstration showing ways designers and manufacturers might use it:

RELATED CONTENT

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

Winning New Jobs With Online Bidding

The digital revolution is hitting the business of the multiple-spindle automatic machining--in two distinct forms, no less. Twenty-five years after the first wave of digitization in manufacturing (numerical control) its linear descendant, computer numerical control or CNC, is changing the way screw machine shops do business.

-

Swiss Shop Chooses CAM Over Hand Programming

This shop’s manual (by hand) CNC programming was slowing it down until it discovered a CAM software for Swiss-type lathes.