Approximately 2,200 manufacturing professionals attended the Index 2023 open house in Germany earlier this year to see the latest in the company’s machining technology and production capability. (Photo credits: PM)

Travel-wise for Production Machining, the middle of this year for me has been enjoyable and educational, albeit slightly extreme.

At the end of April, mere days after returning home from a successful Precision Machining Technology Show (PMTS), I hopped on a plane to attend Index’s 2023 open house at its headquarters in Reichenbach/Fils, Germany. (This was soon followed by two other week-long trips to other German manufactures’ open houses.)

Featured Content

Inside Index

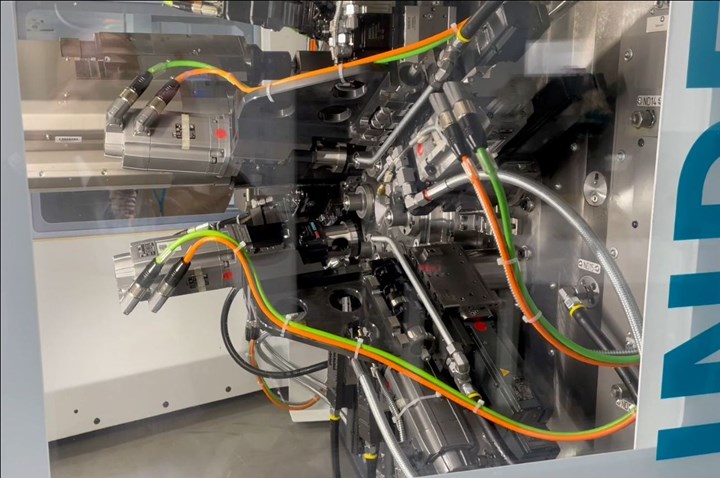

The Index event was a mini-trade show of sorts, with a number of new Index- and Traub-branded machines in action as well as software and equipment offerings from 25 other companies. Approximately 2,500 people attended the event. Roughly 2,200 were manufacturers and the remaining were from the 25 other companies that exhibited at the event as well those from Index subsidiaries around the world. The tech center area in the Reichenbach facility featured a number of new Index- and Traub-branded machines. These included:

This TNX220 turn-mill included the company’s iXcenter L automation concept using a robot cell placed in front of the machine to which various modules can be docked from two sides such as this Renishaw Equator gage.

B500 universal lathe. This now provides more machining options in a new long version with a turning length of up to 1200 mm. It can be fitted with an optional 18-station radial turret.

ABC CNC automatic lathe. The new version features Y-axis motion as standard and is available with FANUC controller. In addition to Y-axis motion, its upper turret offers an electronic indexing axis, height adjustment and the ability to fit twin tool holders.

TNL32. Based on the Traub TNL20, Index has developed the Traub TNL32 compact sliding headstock automatic lathes which offers the small footprint of the TNL20 with a 32-mm bar capacity. Like other TNL machines, the “compact” 32-mm variant is said to deliver productive sliding and fixed headstock turning for workpieces of medium and high complexity.

This G420 turn-mill is equipped with a FANUC robot with exchangeable gripping units.

TNL12. The company says this smaller Traub-branded sliding headstock automatic lathe can now be easily converted to a fixed-headstock lathe while having improved kinematics compared to previous models.

TNX220. This redesigned turn-mill is the successor to the Traub TNX65 milling-spindle version with 76-mm of spindle clearance, 200-mm chuck diameter and increased turning length of 900 mm. At the event, it included iXcenter L automation using a robot cell placed in front of the machine to which various modules can be docked from two sides such as pallet/rack modules, equipment for deburring, cleaning, or laser marking, and a measuring/testing station. This is an example of Index’s Closed Loop solution for autonomous production.

G320. This turn-mill featured new iXtools additional tool magazine, which offers up to 392 tool locations for either redundant tooling or to support multiple machining jobs.

The MS24-6 CNC multispindle has a large maximum bar diameter, but remains compact. An essential element is the Index quick clamping system with integrated W-serration on the cross slide.

MS24-6. Compared to its MS22-6 predecessor, this CNC multispindle has a slightly larger maximum bar diameter but remains compact and provides numerous features. Given decreasing batch sizes, the optimized setup concept is increasingly important. An essential element is the Index quick clamping system with integrated W-serration on the cross slide.

Index has developed the Traub TNL32 compact sliding headstock automatic lathes which offers the small footprint of its TNL20 with a 32-mm bar capacity.

MS22-8. This CNC multispindle has eight main spindles and as many as two swiveling synchronized spindles and enables the use 16 tool carriers. It can be used for eight-spindle machining with simultaneous backworking operations. For simpler parts, it can also be used as a double four-spindle machine, opening up the ability to further reduce cycle times by simultaneously producing two workpieces.

In addition, various elements of automation were on display as well as examples of Index’s iWorld cloud-based platform that covers aspects of a machine including researching specifications during the purchasing process, monitoring and optimizing operations, and requesting machine service and ordering spare parts.

Virtual Machine is digital copy of an Index machine, said to offer identical behavior of the virtual and the real machine.

Plus, the event included tours of the manufacturing facility there as well as in nearby Deizisau and Esslingen. (It’s always nice to see a company’s own machines making new machines; see the slideshow above.) In addition, there were various presentations about new technology with the chance to ask questions and network, too. One interesting example is a new approach to high-speed thread whirling developed in conjunction with P.H. Horn. (Stay tuned to learn more about that.)

One tooling concept we learned about during a side visit to Haimer’s global headquarters and manufacturing facility in Igenhausen, Germany, which is expanding its tooling offerings for turning centers, is its shrink-fit collets.

And as a bonus, we took a side visit to Haimer’s global headquarters and manufacturing facility in Igenhausen, Germany, which is expanding its tooling offerings for turning centers. This includes shrink-fit collets as well as the Duo-Lock modular interface for cutting tool heads available in ER collet versions for driven tools on CNC turning centers. The company also explained the value of balanced tool assemblies for milling and grinding operations.

It’s valuable if you have the time to visit machine tool builders’ operations be they here in the States or abroad. You can make good industry connections, learn about new machining technology and see in person what goes into the design and build of that equipment.

RELATED CONTENT

-

Advancements in Thread Whirling Tooling Technology

Many understand the advantages of thread whirling on a CNC Swiss-type. However, new tooling technology for this thread-machining process can further improve cycle times and reduce cost per part.

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.

-

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.