Editorial, News, and Products

The Advantages of Automated Shopfloor Gaging

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.

Precision Machining Technology Review October 2023

Production Machining’s October 2023 technology showcase includes some of the latest technology from Tungaloy-NTK America Inc., Renishaw, Walter USA, Seco Tools and Haimer USA.

Automated Inspection Transforms Medical Manufacturer’s Quality Control

Manual steps for part inspection have been eliminated with a new CMM process using more advanced software and strategies such as using a combined scanning/touch-trigger probe.

Renishaw Data Platform Promotes Connected Shop Floor

Renishaw Central collects metrology, status and alarm data from connected devices across the shop floor.

Seeing Multitasking, Automation and Digitalization at Index’s 2023 Open House

A mini trade show of sorts, the event held earlier this year in Germany offered an opportunity to see the machine tool builder’s equipment in action as well as take tours of its various manufacturing plants.

Verisurf Ultrasonic Thickness Inspection Enhances Renishaw RUP1 Probe

Utilizing Verisurf’s Inspection Plans dynamic surface points tool creates automatic ultrasonic thickness measurements which are stored and presented through a graphical balloon, providing report users with an easy-to-read thickness map associated with the inspected component.

High-Speed Gaging of Precision Machined Parts

PMTS 2023: Using a parallel kinematic structure, this device enables high-speed scanning and rapid moves between features for accurate machined part gaging.

Shop Finds Value in Simple CMM Programming

Icon-driven programming enables all shopfloor personnel to perform CMM inspection, not just those in the quality department.

Video Tech Brief: Quality Control is Using the Right Software

This machine shop’s mapping software program runs on its gaging system to increase the accuracy of the probe’s tolerance measurement on the thin-walled aluminum tube machined by the shop.

Renishaw’s Advanced Manufacturing Roadshow Makes Stop in Michigan

The event features presentations with metrology experts answering questions on the significant measurement challenges facing manufacturers, ranging from job shops to high-production environments.

VIDEO: A Unique Innovation Keeps the Wheels Turning

A problem with a bicycle’s two-piece bottom bracket design spurred action from two friends that led to not only a simple solution but to a business venture with in-house machining capability that has become an international supplier to high-end bike manufacturers.

Renishaw NC4+ Blue Expands Range, Improves On-Machine Measurement Repeatability

Blue laser technology has a shorter wavelength which is said to result in optimized laser beam geometry, enabling the measurement of very small tools.

Does A Turn-Mill Have to Turn?

Here’s an example of a shop applying innovative probing, tooling and workholding strategies to enable its turn-mill to machine castings complete.

Vertical Integration Enables Rapid Manufacturing Response

For this contract manufacturer, having myriad machining and manufacturing capabilities in-house enables it to deliver assemblies to customers faster and with higher quality.

New Line of Swiss-Types for Job Shops Eyeing High-Production Work

Mazak now offers the Syncrex line of Swiss-type CNC lathes — its first — targeting machine shops getting into higher volume production of complex parts.

Takumi Adds Renishaw Inspection App for FANUC Control

Using the Renishaw Set and Inspect App, Takumi CNC machine users can create a probing cycle, automatically generate the required machine code for the probing cycle and send it to the control.

Starrett Large Multisensor Vision System Optimizes QC Process

System has dual optical systems and touch-probe capability to measure parts with a diverse range of feature sizes and geometries.

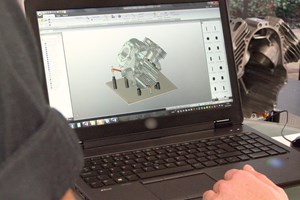

Renishaw FixtureBuilder 8.0 Simplifies Inspection Fixture Modeling

Renishaw FixtureBuilder 8.0 3D-modelling software offers measurement advances.

Renishaw Appoints Denis Zayia to President

Denis Zayia, 33-year industry veteran, is Renishaw's newly appointed president.

Companies Collaborate to Bring Metal 3D Printing to End Users

The companies are offering joint seminars, workshops and training events to customers that practically demonstrate metal AM production from powder to part, with emphasis placed on throughput and machine productivity.

Multi-Axis Calibrator Builds CMM Error Maps in Half a Day

Renishaw's XM-600 laser measurement system communicates with UCC software during the calibration routine, building a CMM error map within half a day.

Apprentices Inspire a New Generation of Engineers

Renishaw recently saw 55 of its apprentices volunteer at MACH 2018 in support of the Education and Development Zone. The initiative involved tours, talks and demonstrations for students aged 11 to 19.

SFP2 Probe Increases Surface Finish Measurement Ability

Renishaw’s SFP2 surface finish measurement is powered by five-axis measurement technology and is automatically interchangeable with all other probe options available for Revo.

Equator 500 System Enables Accurate Gaging Of Larger Parts

Renishaw’s Equator 500 is a larger gaging system that enables the gaging of larger parts, with a working volume of 20” in diameter and up to 16” in height.

GoProbe App Simplifies Machine Tool Probes and Tool Setters

Renishaw’s GoProbe is an enabling technology designed to make machine tool probes and tool setters easy to use.

Renishaw's Gareth Hankins Awarded IET Achievement Award

Renishaw’s Professor Gareth Hankins has been awarded one of the Institution of Engineering and Technology’s (IET) Achievement Awards.

Renishaw Appoints William Lee as Chief Executive

Renishaw has appointed William Lee as chief executive as of February 1, 2018, with previous Chief Executive Sir David McMurtry to remain executive chairman with responsibility for group innovation and product strategy.

Companies Collaborate on Secure Digital Manufacturing

Renishaw and Identify3D are collaborating on providing data protection coupled with contractual and manufacturing licensing from design to production on Renishaw AM systems.

Renishaw-Sponsored Team Finds Formula Student Success

The Cardiff Racing team, sponsored by Renishaw, was recently crowned the first ever UK winners of Formula Student.

UK’s Renishaw Participates in International Women in Engineering Day

The effort is designed to draw attention to how important women are to engineering, career opportunities for women in engineering and to celebrate the accomplishments of women in engineering.

PMTS Knowledge Center: Improving Productivity in the Job Shop

On April 26 at 3 p.m., Renishaw’s veteran industry expert, Dan Skulan, will present the advantages of adopting automated ways to control process variation and introduce the company’s Productive Process Pyramid approach to process control at PMTS 2017.

New Renishaw Facility – Headquarters and More

Renishaw Inc. is preparing to move into a new 133,000-square-foot facility that will act as the company’s new North American headquarters and will provide space for product development, testing, warehousing, and distribution.

Keeping Track of Machine Movement

Renishaw Inc. has introduced a new multi-axis calibrator that provides a laser system using an optical roll measurement and a fiber optical launch system. It’s a portable and compact unit that reduces heat at the source of measurement.

Improve Quality with Probing

The right probing system can go a long way in optimizing on-machine measurement while reducing cycle times and cutting production costs.

Renishaw Lends Support in America’s Cup Event

Renishaw is showing its ongoing support for Land Rover BAR, the British challenger for the 35th America’s Cup at the Louis Vuitton America’s Cup World Series in Portsmouth, England, July 22-24.

Quality Gaging System Cuts Production Costs

With its latest addition of a Renishaw Equator gaging system, High-Tech Enginnering is reaching 100-percent part inspection and zero scrap, which has halved the operator requirements and has reduced part production costs by 27 percent.

Renishaw Celebrates Royal Opening

Renishaw recently opened its Innovation Center, giving the company an additional 153,000 square feet of space to house the R&D and corporate services staff, as well as demonstration, training and conference facilities.

DIY Training

The Additive Manufacturing Division at Renishaw Inc. is picking up the training gauntlet with an internal program called the Applications Academy.

How to Choose and Use Styli

The variety of probe applications on machine tools, CMMs, comparative gages and portable arms makes correct selection of styli usage essential for efficient, reliable and accurate measurement. Here are some key points that can be helpful in choosing the best measurement solution.

Machine Tool Scanning System

Designed to provide process control opportunities for high-value CNC machine tools, this system incorporates a new generation of on-machine analog scanning technology to allow fast and accurate form and profile data capture from both prismatic and complex 3D components.

Programmable Gages Help Create Automation Cell

Conroe Machine (Conroe, Texas) is doing what most machine shops only dream of: hard turning a family of parts around the clock in an unmanned cell that operates a “self-controlled” process.

Renishaw Receives 15th Queen’s Award

Renishaw received its 15th Queen's Award for Enterprise at an evening reception at Buckingham Palace.

Multiple Tool Setting and Inspection Probing

A fine line often exists in the decision of when to invest in additional capital equipment and/or personnel to handle overloaded machines or a backlog of customer requests.

Shop Gains Process Control with Automation

Eliminating variability from the manufacturing flow is a goal for most shops. Automation can allow reallocation of resources to accomplish this.

Manufacturer 'Softens' Hard Gage Costs with Software-Driven Gage

A software-driven comparative gage is starting to soften the cost for numerous hard gages at aero-engine component maker Meyer Tool Inc.

Four Steps to Better Equipment Effectiveness

Lean manufacturing typically gets the spotlight as the path to profit, but before you can have a lean operation, you need to get your processes under control.

The Process Control Imperative

Tough economic times force manufacturers to look for ways to improve efficiency while reducing costs.

Broken Tool Detection In Machining And Turning Centers

Renishaw's TRS2 broken tool detection system uses a "one-box," single-head design to recognize tool reflections, bringing precise, in-cycle laser monitoring to machining centers and other machine tools.