Effective micromachining requires shops to consider a number of process elements beyond just the cutting tools used. (Photo Credits: Big Daishowa)

Micromachining, in which cutting where the volume of chips produced with each tool path is very small, is not a high-speed operation in relation to chip load per tooth. Rather, it involves a high spindle speed due to cutter diameter. The part might be physically larger, but details of the part require ultrasmall profiles achieved only by micromachining. In other words, micromachining is not limited in scope to only miniature parts.

In order to develop an effective micromachining process, shops must consider a number of elements that must work in conjunction with each other to achieve success creating tiny part features. Here we describe tips, trends and technology advances in four prime elements.

Featured Content

Toolholders

To achieve tight tolerances, balance and dynamic runout (the measurement of the spindle at high speeds, performed using laser or capacitance resistance technology) must be controlled to deliver and maintain viable tool life. Much of this burden falls on the toolholder. Balance doesn’t change as spindle speed increases, but the forces it creates increase exponentially with speed. The impacting results appear quickly in micromachining.

When runout occurs, the edge most affected takes over the bulk of the cutting. Uneven wear causes the tool to fail faster than if the tool rotates precisely about the centerline as intended. In one customer application, we found that drilling into a steel workpiece 0.590" deep with a 0.118" diameter carbide drill in a holder with 0.00008" runout accuracy produced 2,300 holes. A holder with 0.00060" runout accuracy produced nearly two-thirds fewer holes, only 800. In this latter scenario, the shop could save hundreds of dollars a month in carbide costs as well as labor costs due to less tool changing by considering a more precise toolholder.

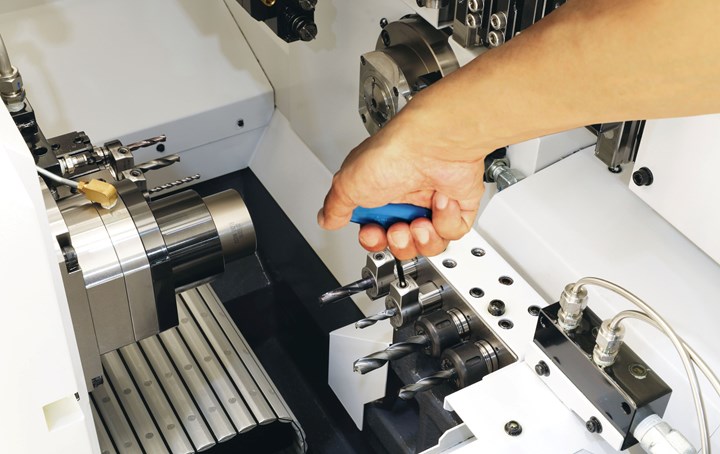

Batch sizes are becoming smaller for many shops. Quick-change tooling on equipment such as Swiss-type lathes can speed setups for new jobs.

Tool holder attributes that can boost production include symmetrical design, a precise concentric collapse of the collet around the cutter and a ball-bearing raceway nut with precision-ground threads. While these characteristics are good rules of thumb, things change fast in this field and, like our customers, we must adapt as trends emerge.

In addition, batch sizes are getting smaller, meaning tool changeovers are becoming more frequent. We are investing a large portion of our research and development (R&D) in tackling this challenge. For example, we at Big Daishowa are working on hydroclamping toolholder systems as an alternative to conventional ER collets. This would make it possible to perform a simple drill change on a gang slide in seconds.

Liquid nitrogen is an alternative to traditional coolants for medical components.

Coolants

Clean machining without the use of water-soluble coolants is a trend, especially in the medical industry, one being driven by the U.S. Food and Drug Administration (FDA). Super-chilled CO2 or cryogenic machining with liquid nitrogen are considered possible replacements. Where protecting small toolholder parts at the nose from coolant has always been a concern, using gas requires more attention for holders to be effective. We are focusing on two designs to accommodate this. One is toolholders that remain completely sealed to outside atmosphere and the other is very small delivery holes in collet faces or clamping nuts that properly restrict gas flow.

Tooling

Optimal results often cannot be achieved by simply increasing spindle speeds or using smaller tools. A deeper understanding of cutters is necessary. We consider tools with diameters less than 3 mm to be microtools. These aren’t simply smaller versions of their macro counterparts. They have geometric considerations all their own. For example, the 1 mm Sphinx drill can run at 80xD. This is only possible because the cylindrical shaping extends further down the tool, closer to the tip, to facilitate pecking and maintain strength.

Tool carbide should be ultrafine grain (nano or submicron size) to ensure high abrasion resistance and good toughness. Coatings are valuable too, but it’s important to understand how coatings can negatively impact microtool performance. Microtools have extremely fine surface finishes and sharp cutting edges. Coatings can fill in valuable space such as a flute on a drill needed for proper chip evacuation, which is critical in these micromachining applications.

In addition, coatings must be ultrathin (<0.001 mm) and smooth. Our experience shows that misapplied coatings result in poor tool life due to breakage. The coating reduces cutting edge sharpness, increasing torque force on the drill. When coating is necessary, consult with the cutting tool manufacturer to provide this directly.

Chips and small tooling naturally do not get along well. Compensating for low spindle speeds with tools that have more flutes support an ideal feed rate, but chip evacuation may suffer. Determining the appropriate chip load as close to the cutting edge as possible enables operations at the highest possible spindle speed, accelerating the cycle and improving surface finish.

HSK toolholders are commonly used for micromachining applications that require high spindle speeds.

Optimal conditions exist when the chip load is relatively equal to the cutting edge radius. Many micro end mills are designed so the cutting edge radius has a positive rake angle to create a shearing action. A chip load less than the cutting edge radius often results in a negative rake angle where the tool rubs rather than cuts. This increases the force required and generates more heat which can result in built-up edges and poor tool life. A chip load significantly bigger than the cutting edge radius often leads to premature failure because the tool is not robust enough to withstand such forces.

Machine Tools

Micromachining requires machine tools with very high sensitivity, fine resolution in the feed axis and very precise spindles capable of high speed with low dynamic runout. For microdrilling operations, specialized micro machines are best.

Micromilling machines are suited for small tools and small workpieces. They are characterized by spindle speeds faster than 50,000 rpm using small HSK toolholders such as HSK-E32, E25, or E20. With the right holder, tool runout can be controlled to less than 1 micron (0.000040") at the cutting edge, ensuring submicron accuracy.

With micromachining, understanding each piece of the equipment puzzle is critical. It’s also important not to make assumptions based on other tools or parts you may have worked with, especially in more standard sizes. Invest the right time and energy in gearing up for the next micromachining job and you’ll get more parts done right faster.

RELATED CONTENT

-

Chip Control

I discovered that chip control actually means controlling chips as they are being cut off of a workpiece.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

Precision Lathe Operations on a CNC Mill

Sometimes a shop doesn’t do enough turning work to justify the purchase of a CNC lathe. But when it needs to produce precision turned parts, even if for a very small lot size, the shop needs a solution.