Editorial, News, and Products

Tips for Choosing the Right Toolholder for High-Speed Machining

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

Big Daishowa Toolholder Increases Precision for Lathes

The Big Capto C3 series provides higher rigidity to minimize vibrations and movement during cutting, improving accuracy and efficiency.

Micro-Drilling: 9 Questions to Answer Before Beginning

Applications for micromachining continue to grow. Successful machining with small tools calls for a different set of process skills on the shop floor.

Big Daishowa, Customers Support Local Schools

The $30,000 in Big Daishowa tooling certificates are redeemable for any Big Daishowa product, including toolholders, boring tools, cutting tools and workholding products.

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Big Daishowa Adds 2 Upgrades to Measurement Portfolio

Big Daishowa adds 360-degree LED indicator and Swiss-lathe solution to its Base Master lineup.

Big Daishowa Incentive Supports Manufacturing Training Programs

Through the end of the year, Big Daishowa will donate a tooling certificate valued at 20% of every order from an NTMA member company to the buyer’s school of choice.

Production Machining’s November 2022 News Highlights

Production Machining’s November 2022 news highlights include an event partnership update, industry award, new on-the-job training process, support for manufacturing training, software collaboration and company expansion.

EWA Fine Boring Head for Fully Automatic Closed-Loop Operations

IMTS 2022: Big Kaiser’s EWA Automatic Fine Boring System is said to perform closed-loop boring operations without a human operator, eliminating the need to stop the spindle to manually adjust the boring tool and resulting in reduced cost, improved accuracy and minimized scrap.

Big Daishowa Upgrades Base Master Touch Sensors

Enhancements include an LED indicator for full series and a side handle for maneuverability on the Master Mini model.

Production Machining’s May 2022 News Highlights

Some of the cutting industry’s latest news includes research and development for new digitization solutions/processes, comprehensive applications support with specialized production technologies, e-commerce, advanced analytics and more.

Big Daishowa Promotes Herman to Sales VP

Mike Herman has 40 years of experience, including 10 years at Big Daishowa Inc. (formerly Big Kaiser Precision Tooling Inc.).

Precision Machining Technology Review January 2022: Toolholding

Production Machining’s toolholding showcase includes Schwanog, Somma Tool, Big Kaiser (Big Daishowa), Allied Machine & Engineering, Kaiser Tool Co. and Exsys Automation.

Does A Turn-Mill Have to Turn?

Here’s an example of a shop applying innovative probing, tooling and workholding strategies to enable its turn-mill to machine castings complete.

Big Kaiser’s Hydraulic Swiss-Type Chucks Enable Faster, Safer Tool Changes

Expanded line includes Standard Type available in inch sizes, F Type for easy cutting tool changes and R Type designed to eliminate interference.

Precision Machining Technology Review: Cutting Tool Technology

Production Machining showcases some of the latest cutting tool technology from Horn, Heimatec, Big Kaiser, Tungaloy and Inovatools.

Big Kaiser Presetter Option Speeds Data Transfer to Machining Centers

The system can also be configured to send measurements directly into the numerical control tool’s offset table.

Big Kaiser’s Noventa Cutter has Advanced Geometry for Front, Back Chamfering

Tool transforms chamfering process to improve cycle time, tool life and surface quality.

Big Kaiser EWA Boring System Compensates for Cutting Edge Wear

When used in conjunction with in-process measuring systems, the closed-loop boring system can automatically compensate for cutting edge wear, resulting in less scrap, improved accuracy and considerable time savings.

How Diligent Are You About Toolholder, Spindle Cleanliness?

Big Kaiser offers insights in how to best clean and maintain cutting tool assemblies to ensure CNC machine tools operate at optimum performance.

Big Kaiser UniLock System Stabilizes Tall Parts

Big Kaiser’s UniLock Stabilizer 50 system can easily adjust to new parts – making machining more efficient and cost-effective.

Big Kaiser Drill Suited for Low Cutting Speeds

Big Kaiser’s Nirox drill from Sphinx suited for low rpms.

Big Kaiser Chip Breaker Inserts Improve Surface Finish

Chip breakers designed for finishing aluminum components.

Big Kaiser Presents Fourth Annual Donation to NRL

Customers and partners of Big Kaiser team up to generate a $7,283 donation to benefit the National Robotics League.

Big Kaiser Adds New Inserts to its Offering

Big Kaiser Precision Tooling is adding more than 30 pressed-geometry carbide inserts for its tools.

Big Kaiser Announces Promotion, Multiple New Hires

New sales engineers, district and sales managers named at Big Kaiser

Big Kaiser Ramps Up Green Initiatives

By switching to unleaded steel and recyclable packaging, the company will reduce both its own environmental footprint and that of its customers.

Big Kaiser Offers Chip Blower for Cleaning Parts and Tables

Big Kaiser’s Chip Blower is designed to make removing chips and coolant from parts and machine tables fast and easy, the company says. The Chip Blower automates in-machine cleaning of coolant and chips by delivering high-volume air flow with spindle rotation.

Big Kaiser Expands BBT30 Toolholder Offering

Big Kaiser has added inch standard sizes for the U.S. market to the production of its Big-Plus BBT30 basic arbors (shell mill holders, end mill holders, shrink fit and blanks).

Big Kaiser Moves Production of CAT50 Smart Damper for Milling to U.S., Expands Offering

The Smart Damper is a damping system that eliminates vibration to enable fine surface finishing and higher metal removal rates.

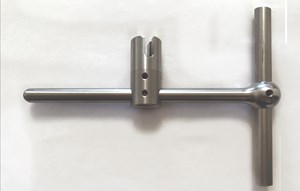

Setup Options for Swiss Automatic Lathes

A hydraulic chuck and a counter-balanced centering tool, originally developed as in-house solutions, are now available to address the limited working space that is common in Swiss machining.

Big Kaiser's Stainless Steel and Aluminum Insert Grades for Milling and Chamfering

Big Kaiser’s set of insert grades for its indexable tools—C-Cutter Mini, C-Centering Cutter and Fullcut Mill—are optimized to extend tool life in stainless steel or aluminum.

Improve Efficiency with Big Kaiser’s ChipFans and T-Slot Covers

Big Kaiser’s ChipFans and T-slot covers are accessories that help machines reach maximum levels of productivity, even during downtime.

Index Cutter Heads with Big Kaiser’s Contact Grip

With the addition of the Fullcut radius mill (FRM) and the ball end mill (BE), the Fullcut mill contact grip series now features four connection sizes and seven cutter types.

End Mill Cutter Ideal for Machining Undercuts, Deburring and Multi-Axis Machining

The Lollipop can be used in three-axis and five-axis applications, although five-axis applications are more common.

Big Kaiser's Twin Cutters Help Minimize Tooling and Cycle Times

Big Kaiser’s Series 319SW twin cutter boring head is said to solve virtually any other holemaking problem for the range of 0.787-8.000”, according to the company.

Big Kaiser Donates to NRL Three Years in a Row

Big Kaiser presented a donation for $6,675 to benefit the NTMA’s National Robotics League (NRL). The donation was the result of a year-end promotion by Big Kaiser, giving back to the association a percentage of every order by an NTMA or AMT member company.

Big Kaiser Dyna Force Corrects Retention Force

Big Kaiser’s Dyna Force is a device for measuring the retention force of machine tool spindles.

Big Kaiser UniLock Stabilizer Supports Tall Parts

Big Kaiser’s UniLock stabilizer system provides lateral support for tall parts during machining, welding or assembly processes and enables the transfer of loads down to the table or base.

Heule Tool Line Selected for Award

Heule Precision Tool’s BSF tooling has been selected as a finalist for the Swiss-American Business Council (SABC) Innovation Award for 2018. The automated Back Spot Facing tool was chosen for its ability to reduce production costs while improving product quality in high production manufacturing environments.

Big Kaiser Hydraulic Chucks Change Tools Quickly

PMTS 2019: Big Kaiser’s hydraulic chucks use a single wrench, enabling quick change of cutting tools on a gang slide.

Jet Coolant Nut Improves Surface Finish

Big Kaiser’s Mega Micro-Coolant Nut is designed to provide precise coolant supply to micro-cutting tools applications at high speeds.

Buy a Precision Boring Kit; Gift One to a School

Until the end of the year, purchase a precision boring kit from Big Kaiser and the company will send an identical one for free to the educational institution of your choice.

Mini Indexable Bar Bores Small Parts

Big Kaiser’s 4-mm mini indexable boring bar is especially useful for small component machining.

Big Kaiser Raises Money for Workforce Development Program

The company will donate 2 percent of orders made by NTMA companies through the end of the year directly to the National Robotics League.

Capto C4 Toolholder Rotates and Turns for Lathes

Big Kaiser expands its range of Big Capto toolholders with a size addition, C4, which is a quick-change system for turret tooling on lathes.

Hydraulic Chucks Clamp in Three Turns

Big Kaiser introduces hydraulic chucks for Swiss lathes.

Multifunction Cutter Starts Holes in Solid Pieces

The C-Centering cutter uses a specialized insert that can start a hole from a solid piece, according to the company.

Big Kaiser Announces New Marketing Communications Manager

Gillian brings more than 20 years of experience in content strategy to the role. She has worked on the marketing teams for several manufacturers—most recently at a precision metrology company.

Torque Fit Tightening Fixture Ensures Precision

Big Kaiser’s Torque Fit is a tightening fixture that is designed to ensure that a collet chuck is correctly tightened.

Dyna Contact Gage Inspects Machine Spindle Tapers

Big Kaiser’s Dyna Contact precise ceramic taper gage is used to check the geometric accuracy of a machine spindle taper by visually comparing the contact of the gage to the spindle.

Base Master Red Touch Sensor Ensures Accurate Operations

Big Kaiser’s Base Master Red is a high-precision touch sensor that can be used with machines and materials, including non-conductive cutting tools, workpieces and machine tools.

Big Kaiser Covers Key Topics at Breakfast & Learn

Big Kaiser Precision Tooling held its annual 3-day Breakfast & Learn event, with technical presentations and an open house that featured demonstrations of the company’s tool presetters, tooling, and zero-point workholding solutions.

Level Master Wireless Allows Simultaneous Measurement

Big Kaiser’s Level Master Wireless supports an accuracy of up to 0.01 mm/1 m and allows simultaneous measurement with multiple detectors.

Big Kaiser Celebrates 70 Years

It has been 70 years since Mr. Kaiser started his success story with strong will, much faith and a little bit of luck. Many things have changed in the world of manufacturing and technology, but the quality standards of Big Kaiser Precision Tooling are unchanged, the company says.

Uniflex Clamping System Designed to Hold Uneven Parts

Big Kaiser’s Uniflex 3D zero-point clamping system provides vibration-free holding of the part when multiple clamping is used and has low-wear against tools.

Modular Round Chamfering Tool Cuts in Tight Spaces

Big Kaiser’s R-Cutter CKB type is a modular round chamfering tool that offers an insert geometry that is said to provide extreme sharpness.

HDC Straight Shank Toolholder Handles Clearance Applications

Big Kaiser’s HDC Straight Shank holder has a slim design that provides balance, concentricity and reach for confined areas and can be clamped into other base holders to extend overall reach of the tool assembly and avoid the need for special tools.

Chuck Clamps Ultra-Small End Mills without Reduction Sleeve

Big Kaiser’s super slim type of hydraulic chucks (HDC) for HSK-E25 machine spindles are toolholders that can clamp ultra-small end mills and drills directly, without needing a reduction sleeve.

SW Smart Damper Rough Boring Heads Absorb Vibration

Big Kaiser’s SW Smart Damper rough boring heads with CKB modular connection system’s damping capability minimizes the effects of high frequency oscillations, absorbing vibration effectively and allowing higher machining accuracy.

Indiana High School’s Precision Machining Program Receives One-of-a-Kind Donation

Big Kaiser Precision Tooling recently donated an Andretti-Autosport-branded tool management system to the Precision Machining program at Plymouth Community Schools.

Live Demo Video: New Digital Boring Head and App

The EWD EVO digital boring head from Big Kaiser connects with newly developed smartphone and tablet app.

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

New Micro Engraving Tools Available from Big Kaiser

The solid carbide engraving cutters are designed to provide sharp, positive cutting geometry, resulting in burr-free surface finishes and smooth transitions.

Protecting Against Tooling Pullout

When milling heat-resistant super alloys, tool pullout is a familiar occurrence. This heavy duty milling chuck helps keep your tooling in place and your machine in motion.

Webinar: Micro Cutting Tools and Toolholders

Register now for Big Kaiser's live, online presentation covering how modern technology and techniques can be used to increase productivity and ROI in micro manufacturing applications (October 21 at 2 p.m., EST).

Presetters Make Way to Swiss-Type Machines

Manufacturing developments in presetters are now available to Swiss-type machines to ultimately increase their productivity and quality control.

Speroni a Winner in the Red Dot Award 2014

Speroni and Big Kaiser announce that the Speroni STP Futura line of tool presetters has won the 2014 Red Dot International Award for Design Quality.

U.S. Manufacturers Tour Kaiser Switzerland

A group of U.S. manufacturers recently visited the Kaiser headquarters in Zurich, Switzerland, touring the assembly and machining areas and attending educational presentations.

Turning Heads with Presetters

As lathes and turning machines pivot toward quick-change tooling models from traditional stick tools, presetters present benefits of keeping chips flying while reducing human error and increasing precision.

65 Years in Business

To commemorate its 65th anniversary, Kaiser has opened a second building, co-located with its newly expanded headquarters.

Things are Hot in Japan

Your intrepid reporter just returned from a 2-week romp around Japan, meeting with some of that country’s premier metalworking companies.

Twin Cutter Boring System

The Kaiser 319 SW series is a twin cutter rough boring system with corrosion-resistant boring heads.

Presetting Pays Dividends

Many shops are moving away from centralized toolroom operations and opting instead for distributed tool presetting on the shop floor. The presetting machines available today are accurate, easy to use and provide closed-loop tool compensation on the CNC machine tool, saving significant time during job change-over.

July PM News

Grand Opening Showcases HeadquartersBIG Kaiser Precision Tooling welcomed customers and partners to its new headquarters’ grand opening on April 29-30.

A Fix for Rigid Tapping Errors

Although it is a well-known fact that no one or nothing is perfect, there is comfort in knowing that there are ways to compensate for some imperfection, especially when dealing with machine tools. Most CNC machine tools now offer rigid tapping capability as a standard feature.

April 2010 PM News

Manager of Strategic ProgramsSeco Tools Inc. has appointed Tracie Clarke as its manager of strategic programs.

Micro-Drilling Calls for Considerations

“Tiny” usually comes to mind when the term “micro” is used. So it is easy to assume that micromachining equates to very small parts found in the medical and electronics manufacturing industries.

Increase Production With Setup Reduction

There are considerably more opportunities to improve efficiency than to reduce a tool’s cycle time. All too often, manufacturing companies invest hundreds of thousands of dollars in new machine tools to increase production, or countless hours testing tools to take 30 seconds out of an operation, when they could accomplish more dramatic results with existing machinery at a fraction of the cost.