It’s time to get together with the precision machining industry at the Precision Machining Technology Show (PMTS) 2023 set for April 18-20, 2023, in Cleveland, Ohio, at the Huntington Convention Center. It’s a great opportunity to do in-person research on the latest technology and trends that can strengthen your business. PMTS brings a broad range of technologies together all in one place to make your research time more effective.

Production Machining wants to help kick off your research with a series of PMTS Product Previews. In this group, we’re taking a look at shop management software, including an ERP digital ecosystem that reduces setup time; an automated production intelligence platform that compares target cycle times to actual process performance; software that offers real-time machine monitoring and preventive maintenance; and more.

Before you go to the show, don’t miss PMTS show highlights in Derek Korn’s PMTS feature article and look for more PMTS Product Previews each week until the show! And don’t forget to register for the show.

For all the latest PMTS product highlights, please visit our extensive PMTS Preview Section which includes new PMTS products posted every weekday up through the show’s opening day.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Click on each link below to read the full product post:

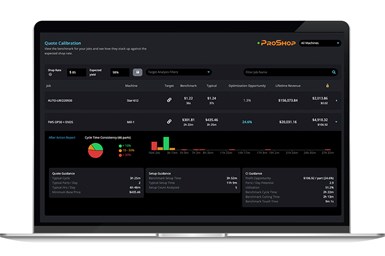

Photo Credit: ProShop ERP

The ProShop ERP digital ecosystem is a combination ERP/MES/QMS solution developed to address the needs of job shops by people with first-hand knowledge of the shop environment. This paperless digital operating platform (DOP) is said to integrate every job shop department — from those estimating projects to shipping. Engineered for small- to medium-sized manufacturing companies, ProShop is said to replace up to five software programs, simplifying project management from start to finish.

Automated Job Costing analytics compare ProShop ERP target cycle times to actual process performance in the Datanomix Automated Production Intelligence Platform. This means machine shops are armed with a full list of jobs to focus on in order to find more margin. Users configure ProShop credentials, and the production platform does the rest, according to Datanomix. The integration automatically matches part numbers in the platform to those from the ERP system and extracts specific target takt times.

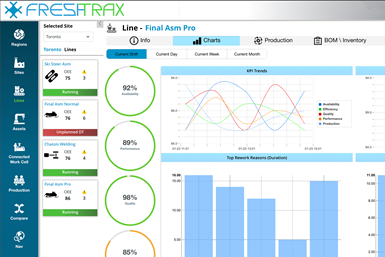

Photo Credit: Caddis Systems

Caddis Systems says its cost-effective, real-time machine monitoring and preventive maintenance management platform can be installed in minutes and deployed throughout one facility or a company’s entire global operation. Caddis can track uptime, downtime, cycles as well as temperature and other key metrics related to psi, flow rate and conveyor speed. Caddis also enables users to create alarms via text or email that sends an alert when a machine has exceeded an excessive threshold such as downtime or temperature.

Photo Credit: EAC Product Development Solutions

EAC Product Development Solutions’ ThingWorx Internet of Things (IoT) platform provides a wide range of pre-built options that are designed to simplify industrial connectivity. With a library of more than 150 device drivers, client drivers, advanced plug-ins and connectors, it enables connectivity to thousands of devices and systems, establishing a single source of data for collecting, aggregating and enabling secure and easy access to data for different job roles at multiple locations.

Photo Credit: ECI Software Solutions

ECI Software Solutions’ JobBoss2 is a manufacturing enterprise resource planning (ERP) software for small- to medium-sized job shops. The software gives shop owners more control over how they scale their businesses, grow revenue and maximize profitability. The software’s key features and benefits include customizable features and workflows so users can make the software work for their business. It can fuel decisions based on data and current business and market conditions.

Photo Credit: Maier Machine Tools

Maier Machine Tools Virtual Engineering system is a digital twin system that maps the current state of the machining operation and provides uniform interfaces to data and services to help predict a system’s reaction to changes. According to Maier Machine Tools, a digital twin enables virtual tests, shortens development times and thus the time-to-market of new products.

Photo Credit: Steelhead Technologies

Steelhead Technologies says it offers an ultramodern software solution for managing job shops with a highly customizable, cloud-based platform that can be precisely tailored to drive data-based management. The software features an all-in-one dashboard that enables employees to access targeted information applicable to their responsibilities. The job shop software is designed specifically for the process manufacturing industry.

Landscape Source: Caddis Systems

RELATED CONTENT

-

From accounting and order tracking to scheduling and inventory management, this workholding equipment supplier is only beginning to realize the full benefits of its ERP system.

-

A fully integrated shop management system will help attract new customers, deal with constant change and manufacture more cost effectively.

-

MachineMetrics Inc. has identified a gap in machine monitoring, as manually tracking data can be inefficient to track and can be inaccurate and reactive, but real-time data allows companies to make fast, proactive decisions to bring efficiency to their processes.