Mazak Horizontal Turning Center Enables Versatile Machining

Appears in Print as: 'Horizontal Turning Center Enables Versatile Machining'

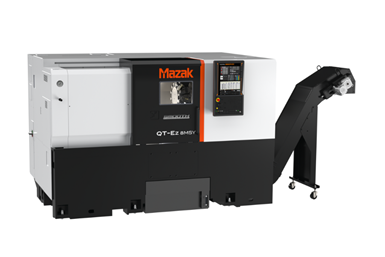

The QT-Ez 8MSY horizontal turning machine integrates seamlessly with bar feeders and robots, and accepts many additional options to tailor it to the needs of any shop.

#horizontal-and-vertical-lathes

Mazak’s QT-Ez 8MSY horizontal turning machine features milling and Y-axis capabilities paired with a second turning spindle. The versatile, automation-ready machine also integrates seamlessly with bar feeders and robots, and accepts many additional options to tailor it to the needs of any shop.

The QT-Ez 8MSY features a 20" bed sports an 8" chuck as standard equipment, with a 6" chuck as optional. Available machine turrets include two-axis drum style with a bolt-on or BMT55 turret for rotary tool applications.

The QT-Ez 8MSY uses an A2-6 spindle mount with 5,000 rpm, 20 hp (14.9 kW), 123 ft-lbs (17 Nm) of torque and a 2" (50.8 mm) bar capacity. It handles parts up to 23.47" (596 mm) long. The turret milling spindle offers 6,000 rpm with 7.5 hp (5.59 kW) and 25.8 ft-lbs (3.57 Nm) of torque. A 6,000 rpm second turning spindle with a 5" chuck accepts an optional through-hole package for shaft transfer applications.

For further productivity, the QT-Ez 8MSY accepts a range of automation solutions from simple bar feeders and parts catchers to full cooperative robot installations, such as Mazak Automation Systems’ cobot cell system models, the CC-10 and CC-16.

RELATED CONTENT

-

Grob Mill-Turn Machining Center Provides Flexible Performance

The G550T mill-turn universal machining center offers optimized milling and turning performance for a broad range of part materials in one setup.

-

Emag VT 4-Axes Lathes for Shaft Production Maximum Performance

IMTS 2022: The lathes are said to provide short cycle times, high-precision machining and safe processing with the VT series of turning machines literally turning the classic horizontal machining process on its head.

-

Heidenhain AMO Speed Sensor Optimizes Main Spindle Functions

The speed sensor provides speed data and supports the capture of that spindle’s operating status data to optimize the operations of milling and turning machines.