Workholding System Features Quick-Change, Modular Design

PMTS 2023: Mate Precision Technologies’ 52/96 workholding system is engineered to maximize holding power for 3-, 4- and 5-axis machining centers to improve manufacturing productivity.

#PMTS

Edited by Angela Osborne

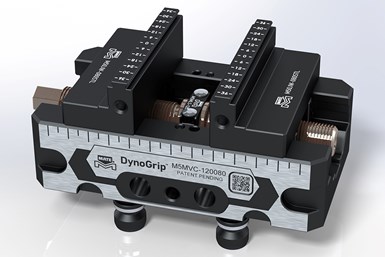

Mate Precision Technologies’ DynoGrip self-centering vise. Photo Credit: Mate Precision Technologies

Mate Precision Technologies’ 52/96 workholding system is engineered to maximize holding power for 3-, 4- and 5-axis machining centers. The company says the system reduces setup times and process variability, while providing accuracy and repeatability in a compact, quick-change, modular design.

The system is also compatible with similar 52- and 96-mm, four-post pull stud configurations from Lang, Jergens, 5th Axis, Gerardi and more.

The system features Mate’s DynoGrip self-centering vises, which include quick-change jaws that are hardened, interchangeable and reversible. No tools are required to attach or remove. They also offer an anti-Lift Design in which the pusher and jaw exert downward force on the piece part. Synchronized timed threads on both the lead screw and pushers enable repeatable precision centering with interchangeable replacement components. The vises are coated with Black Diamond surface treatment to maximize life.

For factory automation, the workholding system includes a QuickSpecs 2D bar code tag product identification system which is smartphone enabled and 3D-graphic supported, enabling real-time access to critical user data, CAD models and potential integration into user’s business systems. The system also supports common robotic interfaces and palletizing systems.

Going beyond machining, the system can be used in a variety of applications such as inspection, CMM, cleaning, washing, assembly and additive manufacturing.

RELATED CONTENT

-

Thoughts about PMTS, Machining Automation

Turning technology, as was displayed at the Precision Machining Technology Show, is more advanced than ever and machine shops should continue to identify processes of all types that can be automated.

-

Dillon Claw Jaws for Secure Workpiece Gripping

The jaws are designed to bite into the workpiece, providing increased holding power during turning operations.

-

PMTS 2021 Product Preview: Multipurpose Machining Centers

Learn about some of the new multipurpose machining centers that will be on display at PMTS 2021.