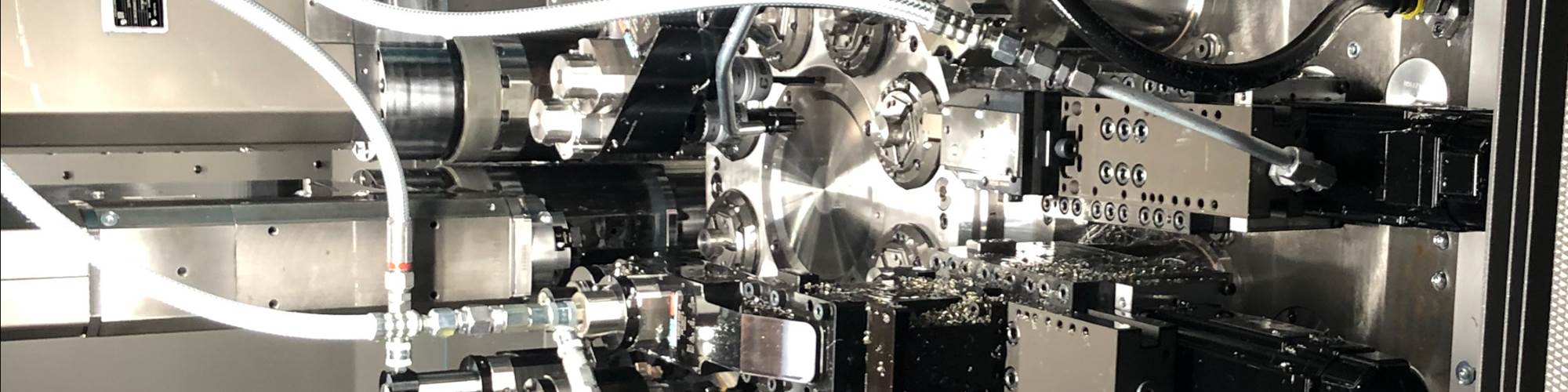

Since opening in 1996, MetalQuest has focused on adopting multitasking technology. Its latest addition is this eight-spindle multi that currently runs a family of five parts.

When Scott Harms started his MetalQuest contract machining business in 1996, the company president set it up to be different from others. The Hebron, Nebraska, company’s first machine was a three-axis CNC lathe with live tooling. The goal was to make multitasking its niche, machining parts complete rather than running them across a lathe and a mill as other shops commonly did at the time. Today, all of its machine tools, sans one in its tool room, have some combination of subspindle and live tooling. The company also has 13 FANUC robots in its now 51,000-square-foot facility, buying them directly from FANUC and integrating them itself.

MetalQuest focuses on medium- to high-volume work for a range of industries, using a comprehensive, in-house shop management system developed by company Vice President and COO Scott Volk that tracks all operational metrics. One job it has been running since the early 2000s is a family of five parts having similar cylindrical geometries with hex and burnished features. The shop originally ran those parts on three Y-axis turning centers with live tooling, but this job was only marginally profitable using that equipment. In addition, the shop previously used hex stock (12L14 steel) for this job because the parts had a hex feature and there was less overall material to be removed, compared to traditional round bar stock. However, the hex stock tended to be bent, so the shop switched to round bar stock. This further extended cycle times due to the additional material that needed to be machined away.

Featured Content

Harms didn’t want to jettison this job, though, because the application was not for the oil and gas market, a market he felt the shop had been too heavily focused. Instead, it made more sense to find a more productive way to machine this particular family of parts to remain more diversified in terms of the industries the shop served.

This type of multitasking machine was the next logical step for our shop. — Scott Harms

Cycle times have been reduced from nearly two minutes on Y-axis turning centers to 15 seconds on the multi-spindle machine.

The answer came in the form of an eight-spindle Index MS40-8 multi-spindle machine, the shop’s first multi. “Given our focus from day one on adopting equipment, technology and processes that other shops don’t have, this type of multitasking machine was the next logical step for our shop,” Harms says.

“The decision to purchase this multi-spindle boiled down to satisfying three needs,” Volk adds. “We wanted more profitable parts, we wanted to diversify from oil and gas, and we wanted to add technology that further sets us apart from other shops. This machine checks all those boxes.” (See video of machine move-in day at gbm.media/movein.)

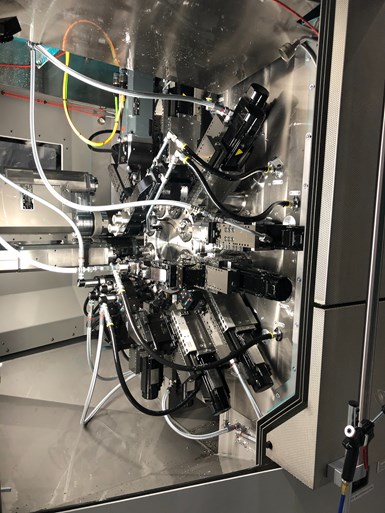

The heart of this machine is its compact spindle drum that Index says uses a three-piece Hirth coupling to enable precision machining at each position. The spindles in the drum are fluid-cooled and offer infinitely variable speed control. MetalQuest’s machine was also fitted with two swiveling synchronous heads (pickoff spindles) for backworking operations.

A part inspection station with various measuring instruments, including a surface roughness gage as well as a computer to access MetalQuest’s proprietary shop management system, was added near the multi-spindle machine.

“Depending on the part, backworking can be a limitation of the multi-spindle machine platform,” Harms explains. “If you have only one backworking spindle and the part requires a good bit of backworking, then that longest backworking process dictates part cycle time. We specified the second spindle to ensure long backworking operations wouldn’t be a bottleneck for future parts we’ll likely run across this machine beyond the current family of five.”

For this family of parts, the multi-spindle machines 30,000 parts per month/450,000 parts annually. Harms says this represents approximately 45% of this machine’s capacity. Cycle times have been reduced from nearly two minutes to 15 seconds, compared to the Y-axis turning centers. Plus, switching this work to the new multi-spindle opened up capacity on those other three turning centers to run different jobs.

Changeover to a new part in the family is fast because the shop uses the same diameter of steel bar stock for all parts, eliminating the need to change barfeeder collets. A change of a few cutters might be all that’s needed.

Dedicated Presetter

The multi-spindle machine’s first day of production was January 15 (I happened to be visiting the shop that day.) MetalQuest also purchased a Zoller Hyperion tool presetter (its third presetter) specifically for use with the multi-spindle. This presetter has tooling blocks installed on an indexing table, enabling tools to be installed in the same orientation as they would in the machine. It also offers automated tool measurement and has Y-axis movement to enable center height adjustments of boring bars, for example.

This presetter was purchased specifically for use with the multi-spindle machine. Its table includes stations that enable tools to be oriented as they would be inside the machine.

The shop is also making this presetter, specifically its Pilot software capabilities, a more integral part of its shop management processes. Volk says the software “fills in the gaps of what ERP doesn’t do.” He is migrating job setup sheets from his comprehensive, homegrown shop management system to the Zoller software, which can be accessed offline on a PC. This makes sense, he believes, because he feels tool presetting is central to ensuring machining accuracy.

Benefits of a Virtual Environment

Since my visit, though, MetalQuest has won a very significant new job for the multi-spindle that simultaneously uses 59 of the machine’s available 62 axes. Harms calls it an “insane setup,” but Index’s Virtual Machine virtualization software was key in pulling it off.

He says Virtual Machine is a software platform Index offers that is a digital clone of the specific machine, so much so that it’s tied to the machine’s actual serial number. The software enables the shop to safely “run and setup” the machine offline.

“You tool up the entire software environment no differently than you’d do with the actual machine,” he explains. “Every toolholder Index offers has an available .stl file and we can mount them in the exact locations we would in the real machine. From there, we build our list of cutting tools, write the code, set any applicable machine tool parameters and then watch the machine virtually cut the part exactly like the real machine would.”

Harms says this helps the shop verify there will be no collisions, and it’s even possible to virtually measure parts as they are being virtually machined. This is done offline so as not to interrupt production.

“Because of the complexity of this new part, we spent about two weeks programming and setting up the machine in Virtual Machine while the actual one was still running a different job,” Harms explains. “By the time we took the machine offline to set up for the new job, we had all the toolholders organized and ready to install as well as fully proven machining code so we could quickly changeover.”

RELATED CONTENT

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

Get 5-Axis Machining on a 3-Axis VMC

Machine shops want and need to eliminate steps in the manufacturing process. Adding four- or five-axis capability to an existing three-axis VMC is a practical way to achieve five-sided machining using a single setup.

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.