Video: The Advantages of CNC in a Cleaning/Deburring Process

This on-demand webinar from Sugino Corp. offers information on CNC waterjet for cleaning and deburring parts, pressure pumps and nozzle options for the system as well as how to add value to the process.

#basics

Combining waterjet cutting and CNC machining center technologies into a multi-purpose cleaning and deburring station brings consistency, repeatability and flexibility to a parts cleaning process. Don Reeder, general manager – sales, marketing and strategic development at Sugino Corp., presented on this topic in his on-demand webinar, “Benefits of CNC Waterjet for Cleaning and Deburring Parts.”

According to Reeder, with cleanliness standards increasing in difficulty each year, CNC-based cleaning machines will likely become the process of choice for OEMs and tier suppliers around the world.

The on-demand webinar covers the following points:

- The many benefits of using a CNC cleaning system

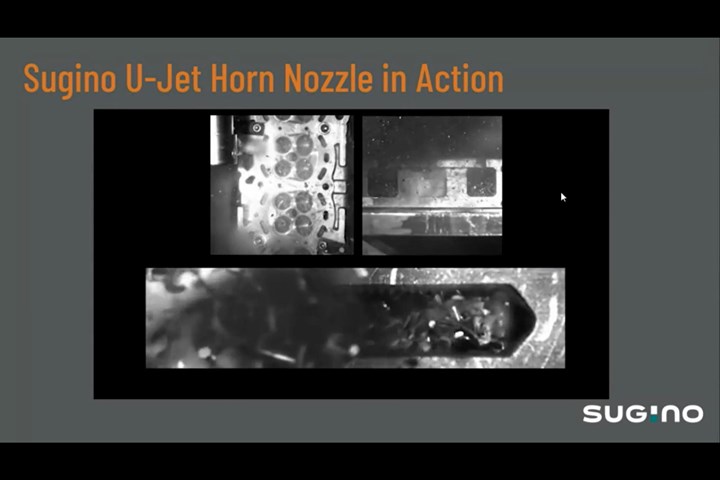

- Videos that illustrate how the CNC system cleans and deburrs

- High-pressure pumps and nozzle options

- Adding value to the process

- How Sugino Corp. can help build the right system for any application

Watch the webinar in its entirety here.

RELATED CONTENT

-

Get to Know Cleanliness Standards

With a small amount of practice, it is possible to understand the underlying motivation of a cleaning standard and to figure out the specific aspects of the specification that are applicable to the customer.

-

The Importance of Drying Parts After Cleaning

Most cleaning processes consist of three steps, not two: wash, rinse and dry. That drying step is absolutely necessary for everything from product finishing to product performance to effective throughput to product quality.

-

Cleaning and Corrosion Protection with Solvents

Protect parts against rust in an efficient and sustainable way.