Editorial, News, and Products

Walter Turning Grades Feature Curved Wiper Cutting Edge

The FW4 and MW4 positive wiper geometries provide a wiper action that can reportedly be used to reduce machining time by using double the feed rate.

Walter Xtra-tec XT Milling Tools Feature Pocket Design

Eastec 2023: Walter’s Xtended Technology (XT) milling tools offer large cross-sections for maximum tool stability and a larger contact surface for a secure seat and reduced surface pressure.

Walter Axial Grooving System Features Two Cutting Edges

The company says a key to the system’s success is the Walter Cut G1111-P holder and AF5 axial grooving chipbreaker system, which are said to deliver strength, reliability, optimum surfaces and high cost efficiency for axial grooving.

Walter USA Relocates US Headquarters to South Carolina

The company is combining its technology center and tooling production facility in South Carolina to enhance the customer experience and improve responsiveness to customer demand.

Boring Series Features Modular Components for Flexible Cutting

Walter says its Precision Boring XT tools yield high surface finishes and are up to three times more reliable and flexible than comparable models.

Walter’s Drilling Grade for Drilling Aluminum

This grade is designed to enable reliable chip removal due to its smooth surface with a reduced tendency toward adhesion and buildup on the cutting edge, thereby increasing process reliability and wear resistance.

Walter Cut DX18 Inserts for Grooving, Parting Off

Insert’s new geometries are designed to improve tool life, process reliability and cycle times.

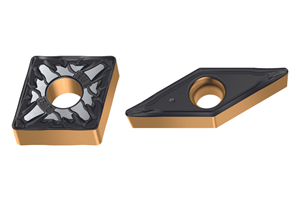

Walter Tiger-tec Gold Inserts for Tough Steel Turning Applications

A highly textured MT-TiCN layer is said to reduce flank face wear and increases toughness due to its multilayered elastic structure.

Walter CBN Grade Insert for Interrupted Cuts, Hard Materials

Line of Walter CBN grade WBH30 inserts was developed specifically for hard turning, handling interrupted cuts in difficult materials.

Walter’s A3001 Anti-Vibration Boring Bar Features Larger Boring Diameters

The boring bar features a large diameter and is designed to provide superior surface finishes with no time-consuming fine-tuning.

Precision Machining Eastec Technology Preview September 2021

Production Machining highlights some of the latest precision machining advances and technology updates that will be showcased at Eastec 2021, Oct. 19-21 in West Springfield, Massachusetts.

Walter CBN Indexable Inserts Designed for ISO K, ISO H Materials

Latest CBN grades are said to provide more productivity and reliability for machining cast iron, sintered metals and hardened steel.

Walter Micro Drill Has Internal, External Coolant Capabilities

Walter USA’s Supreme DB133 solid carbide micro drill delivers high precision and productivity.

Walter’s Boring Bar Features Vibration Damping

Accure∙tec features vibration damping technology for maximum precision.

Xtra·tec XT M5008 Indexable High-Feed Milling Cutter

High-feed milling cutter in the diameter range of 5/8–2" permits high feed per tooth at low axial depths of cut.

Walter Adds TiN-Coated Threading Tool for Small, Medium Batch Sizes

Walter USA’s TC410 Advance HSS-E thread former is a versatile TiN coated threading tool for small and medium batch sizes.

Walter Acquires Melin Tool Company

The acquisition expands Walter's presence in the United States, as well as its round tool offerings.

MC232 Perform Line of Solid Carbide Milling Cutters

The cutters have a corner radius for improved approaches, longer tool life, and greater edge stability.

Walter's HU5 Universal Geometry Improves Metal Removal in Tough Materials

The HU5 has a larger seating surface than double-sided negative inserts. This is said to increase stability and enable deeper cutting depths, feed rates and metal removal rates.

Walter USA Appoints New Regional Channel Development Managers

Appointed were Jagear Novak-Isackson in the position of channel development manager—west zone and Gregg Engler to the position of channel development manager—east zone.

Carbide Milling Cutters from Walter Deliver Productive Roughing

With the new knurled design, the Walter MC319/MC320 milling cutters are designed to require less power while providing high metal removal rates.

Walter CBN Grades for Turning Hardened Steel and High-Temperature Superalloys

CBN grades are said to provide users with multiple benefits, including accurate, high quality surfaces, long tool life, and a higher degree of process reliability.

Helitronic Tool Grinding Machines Offer Two-in-One Concept

These Helitronic tool grinding machines integrate both eroding and/or grinding capabilities into single grinding machine platforms.

Walter Xtra-tec XT Cutters Benefit Milling Operations

Walter’s Xtra-tec XT range of milling tools are designed to achieve productivity and process reliability.

Walter Cartridges Enable Large Component Milling

Replaceable and adjustable cartridges bring the benefits of Walter’s M4000 universal milling system to the machining of larger components.

Walter USA Appoints Regional President

Walter appoints Richard Garrick as President of Sales Region World West.

Walter’s D3120 indexable Insert Drill Designed for Trouble-Free Drilling

Friction resistance and optimum process reliability are highlights of the Walter D3120 drill.

Indexable Inserts Handle Turbine Blade Machining

With its specialized coating technology, the Walter WMP45G Tiger-tec gold-grade is designed to improve turbine blade machining.

Walter's Perform Drill for Small and Medium Batch Sizes

The DC150 Perform 5 × Dc solid carbide drill is the latest addition to Walter’s DC150 Perform line.

Grooving Inserts Deliver Flatness

Walter USA MX system grooving inserts and G3011/G3021 holders feature decreased downtime and boost productivity.

Drill's Precision Ground Surfaces Deliver Accuracy

With precision-ground surfaces and an engineered tip geometry, the DA110 Perform drill from Walter is suited for small- and medium-batch production.

M4258 Cutter Handles a Variety of Materials

The modular M4258 brings both high performance and process reliability to slot milling and other applications.

TC420 Supreme Delivers Reliable Surface Finishes

With its polygon geometry and other design innovations, the Walter USA TC420 Supreme thread former has up to 30 percent lower torque and a better surface finish than is normally gained with thread cutting.

Indexable Inserts Turn Threads in Tight Spaces

The A60 and AG60 Walter Cut MX indexable grooving inserts for small- to medium-pitch threads deliver multiple advantages.

Cermet WEP10 Insert Delivers Long Life and High Productivity

Dimensional accuracy, no need for readjustment and mirror finishes are a few advantages of the new grade.

M4003 Face Mill Delivers Cost and Performance Benefits

Walter’s M4003 face milling cutter can use the same system insert used in the other six styles of milling tools in the M4000 family. It is designed to ensure a high level of production and cost efficiency.

MX Grooving and Parting Tool Offers Superior Chip Control

Walter’s Cut MX grooving and parting tool’s geometries are designed to offer superior chip control, particularly the CF5 sintered geometry.

WCK10 Ceramic Cutting Inserts Improve Productivity

Walter’s WCK10 ceramic cutting grade inserts deliver improved productivity, process reliability and longer tool life because of its wear-resistant ceramic cutting material.

Perform Line Insert Grades Boost Performance and Reliability

The Walter Perform Line of turning tools’s two insert grades, the WPV10 and WPV20, are beneficial to users who have difficulties measuring the tool life of an insert and who change inserts at set intervals.

T2711/T2712 Thread Milling System Machines Large Threads

Walter’s T2711/T2712 thread milling system’s multiple thread sections can be machined simultaneously with high cutting parameters, enabling machining times comparable to those of thread tapping and forming.

Grooving and Parting Grades Used on Steel and Cast Iron

Walter’s Cut GX Tiger-tec Silver CVD grooving and parting grades are for use on steel and cast-iron applications and have been introduced in combination with Walter's geometries UD4, UA4, UF4, RD4 along with plunge grooving and parting geometries GD3 and CE4.

New Venture Poised for Industry 4.0

The synergies made possible by the Walter-Comara collaboration enable Walter to digitize and connect its tools with improved precision and sophistication, allowing optimization of real-time data.

Parting Blade Adapter Delivers Precision Cooling

After flowing through the adapter, the coolant is transferred directly through the parting blade to the cutting zone, targeting the exact point of material removal.

Get the Word Out

The Last Word column in our August issue covers some substantial and important ways in which information is relayed back and forth between buyer and seller.

Knowledge is Meant to be Shared

Having information on multiple platforms, both in print and online, provides the most balanced approach.

Top Business Award Goes To …

This company was recently named a 2013 Top 10 Business of the Year.

Capitalizing on Manufacturing’s Vitality

Most sources indicate that manufacturing in the U.S. is on a very strong path right now.

February 2010 News

Makino in MexicoMakino has opened an international technology center located in Querétaro, Mexico.

November 2009 News

Software Certified by Autodesk InventorGibbs and Associates’ GibbsCAM 2009 has been certified for Autodesk Inventor 2010 software under the Autodesk Inventor Certified Applications Program. Certification is granted only after a product has been thoroughly tested by internal staff at Autodesk.