Video Tech Brief: Dual Thread Whirling on a Swiss-Type CNC Lathe

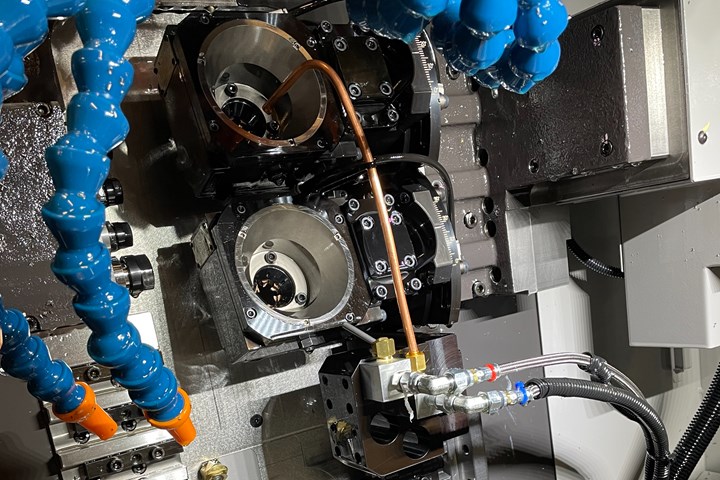

The dual thread whirling units on Tsugami Swiss-type lathes can produce medical bone screws with two different thread leads in one setup, eliminating the need for single-point threading.

In some cases, medical bone screws have two thread leads. Traditionally, these might be machined with two single-point threading operations, or, one thread whirling operation followed by a subsequent single-point operation.

Tsugami/Rem Sales offers an alternate option on its S206-II Swiss-type CNC lathes that can be fitted with two thread whirling attachments. That way, both thread leads can be created in one setup. View the video above to learn more.

RELATED CONTENT

-

Femtosecond Laser Processing in the Medical Device Industry

Recent advances in the laser technology have brought improved capabilities for precision machining—no thermal effects and minimal post processing.

-

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

-

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.