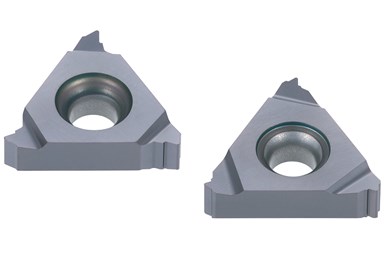

Tungaloy Threading Inserts for Improved Chipping Resistance

Appears in Print as: 'Threading Inserts for Improved Chipping Resistance'

The inserts provide threading applications with long, predictable tool life, while keeping machining costs down, in not only steel and stainless steel but also difficult heat-resistant superalloys.

Edited by Angela Osborne

Tungaloy has expanded its TungThread indexable threading tool series to include full-profile threading inserts with the UN and UNJ profiles in AH8015 grade. The TungThread series offers high-performance indexable threading tool solutions, extending over a range of threading applications from general parts that are machined in CNC lathes and small precision parts in Swiss-type automatic lathes to premium threading of OCTG.

The AH8015 is a PVD-coated cemented carbide grade featuring a hard high-aluminum content multilayer coating which is combined with a tough dedicated carbide substrate. The company says the grade provides the insert with well-balanced wear and chipping resistance.

The AH8015 grade threading inserts now offer the UN and UNJ profiles. The UN (unified thread) is most commonly used on bolts, nuts and a variety of other fasteners, while UNJ was developed to meet aerospace requirements for fatigue resistance.

This expansion provides threading applications with long, predictable tool life, while keeping machining costs down, in not only steel and stainless steel but also difficult heat-resistant superalloys.

The TungThread threading tool series is designed for use with CNC lathes, Swiss-type lathes and multitasking machines. Tungaloy developed this series to address chip control and tool life issues in challenging turning applications. The company is utilizing this technology to offer new generations of grades and optimized chip breakers designed for superior performance while maintaining long tool life to improve efficiency and productivity.

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

-

A Guide to Insert Coating Processes and Materials

Few materials have had a greater impact on our economy and industrialized culture than cemented tungsten carbide.