Thread Whirling Basics

The rapidly increasing demand for high-value threaded parts with exceptionally high length-to-diameter ratios has created a lot of interest in thread whirling technology among American shops and manufacturers.

#basics

The rapidly increasing demand for high-value threaded parts with exceptionally high length-to-diameter ratios has created a lot of interest in thread whirling technology among American shops and manufacturers. Although popular in Europe for more than half a century, thread whirling was used primarily in North America in the production of large worm gears and similar parts for the automotive and related industries. Operations were performed on large, dedicated machines and required high initial investment.

Parts such as bone screws and related devices and customized fasteners for complex defense, aerospace and electronics applications, coupled with the enhanced applications capabilities of modern Swiss-type machines, have resulted in a renewed appreciation of the many advantages thread whirling can provide — especially in the machining of such hard materials as Inconel, titanium and the new stainless steel alloys.

Featured Content

Before rushing headlong into thread whirling, however, it is important to realize that the successful embrace of this technology requires preliminary study, an in-depth assessment of the application(s) involved, and a close working relationship with the tooling supplier. The fact is that unlike many high production processes, thread whirling requires a lot of customization in such areas as machine and tooling compatibility, insert design, and programming options. When these parameters are met, even the most challenging part can be processed to meet high quality standards and high production rates.

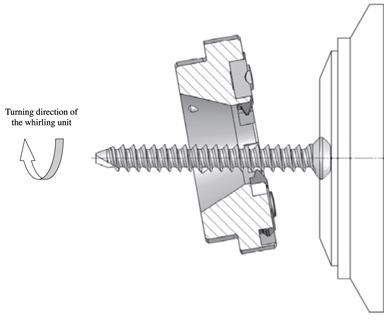

Thread whirling uses a holder equipped with multiple inserts that is mounted into an attachment capable of helical angle adjustments and high speed concentric rotation. The workpiece, which is advanced at a slow rpm, engages the cutting head, which in turn is advanced longitudinally. The combined rotation of workpiece and cutter, and the angle of the tool head, produce the thread pitch required. Depending on the part configuration, the cutter angle can be adjusted to compensate for large helix angles.

Since thread whirling employs multiple inserts, the part is created in a single pass and in a shorter time than with single-point threading. High feed rates, likewise, shorten cycle times. Thanks to the multiple cutting edges, the process delivers very high surface quality and accurate geometry. Cutting is clean with faster chip removal, and proper cutting edge geometry delivers higher concentricity.

Because cutter side clearance is achieved by rotating the whirling spindle, as opposed to relieving material under the cutting edge, inserts have a significantly longer tool life than single-point tools.

Another point of superiority derives from the elimination of specialized support devices and/or fixturing. In addition to the cost savings, setup time is significantly shortened.

Perhaps the most important thing to remember for getting started with thread whirling is the fact that, because of its highly specialized nature, the process requires a different mindset than conventional high speed applications. The toolholders are designed according to different machine types and manufacturers, and it’s necessary to locate a supplier whose equipment line best fits the machine(s) on the shop floor.

The inserts should be specially made to perform the specific application, so the supplier that is selected must meet the quality standards of the shop and offer reasonably fast delivery. The relationship factor is especially important because of the learning curve involved. It is uncommon to achieve optimized performance on the first try. Frequently, it will be necessary to adjust various angles and modify the tooling before the entire process comes together.

With regard to the toolholders, several versions are available for holding different numbers of inserts. Although there is lively debate about the proper number, the reality is that the quantity is dictated by the application and, for purposes of both results and economy, it is unwise to use more than is absolutely necessary.

When Carmex Precision Tools designed our line of thread whirling toolholders for six of the most popular CNC Swiss-type screw machines (Star, Citizen, Tornos, Traub, Hanwha and Maier), our engineers opted for units that could hold three, five, six and eight inserts.

Another consideration involves flexibility. Although the inserts are specialized, it is best to select a toolholder that can be used for various applications. In shops equipped with different makes of machines, it is economical to select toolholders that can accommodate special adaptors for interchangeability.

For maximum tool life, thread whirling inserts should be coated. Carmex is introducing a new thread turning grade called BLU (a harder sub-micron substrate with the latest nanocomposite coating, AlTiN/SiN) and is an excellent choice for heat-resistant materials such as Inconel, Hastelloy, Monel or other nickel-based materials, as well as titanium and austenitic stainless steels.

Most of the parts made using thread whirling are not only high value parts, they are often highly sensitive. One has only to look at the number and cost of medical malpractice suits to understand that a faulty implant device that slips through the process can destroy the fortunes of the surgeon that installed it and the company that made it. Despite the fact that many of these applications require working with some of the hardest materials available, it is critical that part handling processes treat each unit with a lot of respect.

Especially on first runs, it’s necessary to monitor quality carefully to determine the point at which tool wear begins to occur. This varies for each application and, in time, can become much more predictable; but it will be necessary to be alert and to constantly monitor early production.

Despite the multiple cautions and challenges involved, thread whirling is a technology that can deliver quantity, quality and profits if properly applied. Equally important, thread whirling is a state-of-the-art technology that can help win orders by making complex processes more competitive than traditional operations.

RELATED CONTENT

-

5 Process Security Tips for Parting Off

Here are five rules of thumb from Scott Lewis, a product and application specialist at Sandvik Coromant, to optimize the parting off process, and as a result, maximize tool and insert life.

-

Calculating Surface Footage and RPM for Optimum Tool Life

Tech Brief: Calculating Surface Footage and RPM for Optimum Tool Life

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.