How a part is held is often as important as how it is cut. From another viewpoint, how a part will be cut often determines how it needs to be held. Here, we take a look at an assortment of applications and the approaches that can be taken to narrow the workholding options to what will fit best. From barstock to blanks, from tiny parts to thin-walled or irregular shapes, and from Swiss turning to part movement throughout a cell, holding the part securely without damaging it requires a thorough understanding of the advantages and disadvantages of each option.

Proper Workholding Selection

An efficient manufacturing process requires good machine selection, proper cutting tools and the right workholding. The first two areas typically receive substantial consideration, but workholding is often overlooked. The correct workholding selection can increase manufacturing process stability, efficiency and safety.

Featured Content

Choosing the best workholding option requires a close look at many factors. A sealed pullback chuck with high accuracy can improve throughput and part quality in secondary operations.

Workholding requirements can be affected by many factors, including the material being cut, critical tolerance requirements, workpiece shape and dimensions, and frequency of change-over. High volume machining has a different set of requirements than those for a job shop, with closer attention to consistent quality over longer periods of time. Quick-change is often the solution for shorter runs.

A team of experienced workholding engineers can help ensure that all factors are considered in finding the most suitable workholding for a specific job and can help to optimize the manufacturing process with the workholding strategy. Learn more about what goes into choosing the most effective workholding.

Selecting the Right Workholding Solution

Careful workholding selection isn’t only important in turning operations. With manufacturing operations of all kinds using higher cutting speeds that place more force on workholding equipment, choosing the correct system to hold on to the work is trickier than ever. Often, customized solutions are the answer to troublesome workpieces and manufacturing that demand high accuracy and repeatability.

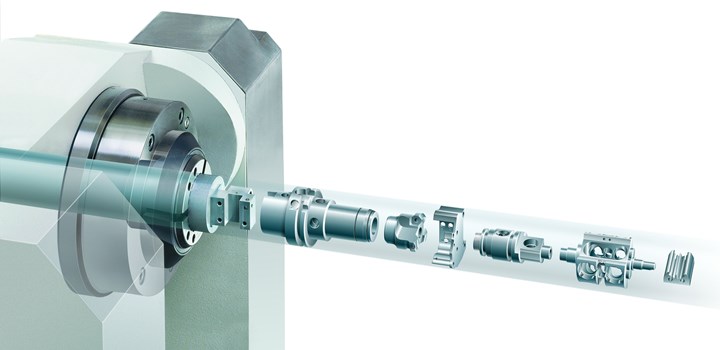

Some workholding systems are designed for adaptability with families of parts. This example shows a basic machine connection (left) and an adaptable chuck (right).

Most situations requiring a custom workholding solution involve a difficult workpiece and/or operating environment, such as holding very thin-wall parts that have a tendency to deform. In these cases, as with others, workholding should meet the needs for rigidity, repeatability and accuracy. But not only does the workholding need to be precise; other areas of the operation should also be reviewed to ensure the best possible results. These include suitability of the production environment and tooling and the volume of work to be performed.

The clamping solution of choice should be one that not only is effective now, but will suit the needs of the shop well into the future. Read more about how selecting the best workholding system for a given application can ultimately lead to a better end product.

Workholding Advantages of Barstock

Barstock is versatile raw material. It’s easily held, easily fed and has significant capacity for many parts per bar. Usually we think of barstock and bar feeders in relation to turning machines. But those same advantages realized in turning operations can also be applied to the vertical machining center.

Using barstock as the raw material for machining complex parts simplifies material holding requirements. Within the bar’s circumference, a large variety of parts can be made using only a collet to hold the bar.

The push to manufacture workpieces in a single part handling to reduce workhandling and cost of production has brought the multi-processing technology of the mill-turn machine. The application of a bar feeder to a VMC provides the ability to continuously supply the machines with blank material. Therefore, as long as the workpiece’s major dimension fits within the circumference of the bar, an unlimited variety of workpieces can be machined, including families of parts.

Understanding CNC Collet Chucks

When considering the purchase of a CNC lathe or turning center, it is important to ensure that the workholding system is matched to both the machine’s capabilities and the type of work that it will be doing. But workholding for turning is usually fairly basic: The selection comes down to chucks or collets.

This quick-change collet system uses a special handling tool to compress the rear of the end of the collet so it can be inserted into the chuck body. Upon expansion, the collet locks into place using a hook and groove arrangement.

As a universal workholding device, a three-jaw chuck functions well for many common turning applications. It can hold a range of part sizes, is capable of operating at reasonable rotational speeds and achieves good accuracies. However, there are many applications where a jaw chuck is not the best workholding option, which has led to the development of a range of alternative solutions. The most common among these is the CNC collet chuck.

Change this Chuck: Save Setup Time

Precision parts machining shops are increasingly faced with the need to accept higher-mix/lower-volume work. Putting a job on a machine tool and running it for long periods of time is not as common as it used to be, and the definition of medium- and high-volume lot sizes has changed.

Reducing changeover time is a goal for most shops. This workholding interface system significantly reduces time required for chuck changeover.

To maximize production efficiency, shops look to shorten the time required to change-over a machine tool from one job to another. In a turning application, one area in which a shop can save time is workholding, generally found in the form of universal clamping devices such as the three-jaw chuck. And one practical solution is a quick-change interface.

Changing jaw chucks on lathes has always been time consuming, but some products are geared towards reducing this bottleneck. Learn about one system, designed for any process requiring frequent change-over, that can reduce the time needed for replacing a three-jaw chuck from 45 minutes to 30 seconds for single-part and small-series production runs.

Workholding for Swiss Turning

Because of its versatility, Swiss turning has found its way deep into the precision turned parts market. To make the most of this technology, a look at workholding considerations is in order.

For the most part, workholding on a Swiss is about collets. On a conventional fixed headstock lathe, the collet and spindle are fixed. They function as a rotary axis only. The Swiss-type moving headstock uses the spindle as both a rotary and linear axis. This design allows for very close coupling of the cross-fed cutter and the point of maximum workpiece support, which is nearest the spindle nose—on a Swiss, the guide bushing.

A number and variety of headstock collets, guide bushings, subspindle collets and bar feeder collets offered for Swiss-type machines are available off-the-shelf and customized.

As a result of this design, long, slender parts can be efficiently turned without deflection or the need for tailstock or steady rest support. The guide bushing is actually another collet that, in Swiss turning, must be extremely precise.

Read about the basics of collet design for Swiss machining, alignment tricks for non-round bar shapes, and how to get the most effective workholding in very small applications.

Applications Determine Workholding Solutions

In turning operations, workholding options often present some difficult choices. While the three-jaw chuck is the obvious choice for certain larger parts, and collet-nose chucks are the clear choice for most low-volume, high-tolerance work, the spectrum of turning jobs is far too broad to be able to chart the best workholding choice for each application.

For some parts, the first operation can run with either a chuck or collet, but secondary operations may require a collet because there is nothing left for the chuck jaws to hold on to.

Most shops find that the majority of their work calls for one or the other, but rarely can a company count on either the three-jaw chuck or the collet nose to cover its whole lineup. Each situation should be examined to determine the most appropriate workholding option.

Read about a contract job shop in Cleveland, Ohio, that faces constant decisions between chucks and collets for handling its parts. For this shop, part size is often used as an initial guideline, but accuracy requirements, cutting speeds and change-over times also come into play.

Handling Parts in a Robotic Cell

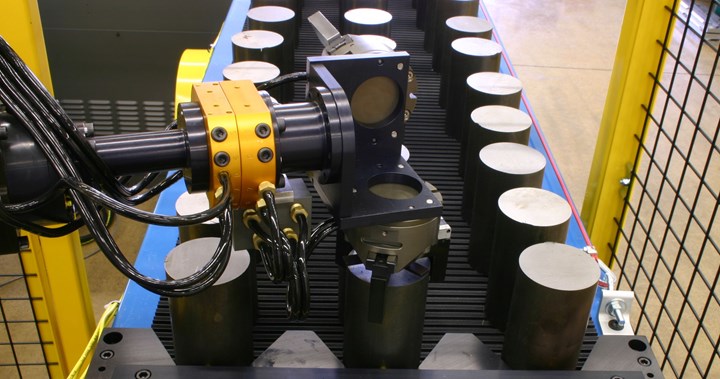

For many shops, workhandling—how a part moves from point A to point B—creates more questions than what the best workholding options are. The more automation is involved in a manufacturing process, the more attention must be given to handling the part.

When automation is involved, discussions of workholding often evolve into a quest for finding the best workhandling processes.

When a shop implements a robotic cell in its CNC machining operations, for instance, the goal is clear: Save money through better spindle use, more efficient use of labor and more consistent production. But special attention must be given to other factors as well, such as grippers, part orientation, guarding, door openers, part in-feed and out-feed devices, vision systems, and the total integration of the mechanical and electrical components.

— ATS Systems

— Chiron America

— Emuge Corp.

— Hainbuch America Corp.

— Kitagawa-NorthTech Inc.

— Royal Products

RELATED CONTENT

-

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.

-

The Effects of Automation on Manufacturing

Companies that are not currently using automation in their manufacturing processes should be considering it.

-

Automating CNC Lathe Part Loading/Unloading

Read about how you can automate the loading/unloading of your CNC lathes to reduce the labor cost on longer running jobs.