Recently, Hashier Machine reached a fork in the road business-wise.

Brothers Pete (left) and Phil Hashier decided to adopt Swiss-type turning for their shop to enable long stretches of unattended machining for parts that often previously ran across multiple machines.

Established in 2006 by Phil Hashier, who was joined by brother and mechanical engineer Pete a year later, the Avon Lake, Ohio, job shop once had 10 employees. The recession that came a couple years after the shop’s start caused it to lay off some employees as many other shops similarly had to do.

Featured Content

But after weathering those overall poor business conditions, the brothers found it exceedingly challenging to bring more people on board, to the point where the shop now has four employees and more than twice that in terms of number of CNC machine tools.

Those machines are certainly capable, including lathes with live tooling and VMCs with fourth-axis rotary tables. Yet, it is still often necessary to run parts across multiple machines to complete them and operators are, of course, needed to tend machines to facilitate that work.

Therefore, the brothers had to determine whether it made more sense to direct their energy toward continuously and proactively seeking shopfloor employees to run its existing equipment or toward becoming familiar with a new, more sophisticated machine tool platform that could enable long stretches of unattended operation during the day and overnight. In October 2021, it chose the latter in the form of a bar-fed, Swiss-type lathe, a first for the shop.

Swiss Learning Curve

One part family in particular spurred Hashier Machine to consider a Swiss-type: aluminum shafts as long as 14.35 inches that ran across two lathes and one mill for a total of three operations. Total cycle time to complete the part was 4 minutes. However, a Swiss-type could offer the opportunity to machine that part complete.

Hashier Machine purchased its Nexturn SA32B 7-axis Swiss-type in October 2021. It currently doesn’t need the machine’s 32-mm capacity, but might at some point down the line.

After considering a number of suppliers, the shop purchased a Nexturn SA32B 7-axis Swiss-type from nearby Absolute Machine Tools. This 32-mm machine features a 10-hp/8,000-rpm main spindle and 3-hp/8,000-rpm subspindle. It has 20 total tooling stations, 8 of them being live at 6,000 rpm apiece. The machine was also purchased with 2,000-psi, high-pressure coolant system and a long-part ejection system for jobs such as the one mentioned above which pushes completed parts back through the subspindle and out of the machine into an awaiting container. In fact, that part, which requires turning, milling, drilling, tapping and knurling, is now dropped complete in 60 seconds on the SA32B.

Here is a sampling of parts the shop has machined complete on its Swiss-type. The Hashier brothers plan to take on more complex work once they become more familiar with the new machining platform.

Because of the long-part ejection system, the brothers chose an LNS Turbo HD low-profile chip conveyor that would offer clearance for the ejection system. On the other end, the machine features a Tracer 32V hydrodynamic-magazine bar feeder that can accommodate 12-foot-long bars. Compared to shorter bar feeders, this enables longer stretches of unattended operation and eliminates the need for a shopfloor employee to saw bar stock into smaller lengths. (The shop plans to purchase a 12-foot bar feeder for any future lathes it might add, Swiss-type or otherwise.) In addition, external LED lights on the bar feeder offer simple, visual monitoring of remaining bar length and any alarms. The bar feeder also features dual internal and external anti-vibration devices that are said to minimize bar whip as well as a polyurethane guide channel designed to damp vibration.

Hashier Machine chose an LNS low-profile chip conveyor so as to offer clearance with a long-part ejection system it uses for some jobs that pushes completed parts back through the subspindle and out of the machine.

Because this was their first experience with oil coolant, the brothers relied on advice from Klaus Miller, vice president of sales for Absolute Machine Tools, who suggested Hangsterfer’s PC 20 given the range of materials the shop machines. According to Hangsterfer’s, the PC series combines its Very High Flash Point (VHF) chemistry and Polar Cutting (PC) technology. As speeds and feeds are maximized, the temperature in the workpiece zone increases, meaning a high oil flash point is desired. In addition, the PC series lubricates the tool as well as the metal being cut, creating optimal metal flow conditions, the company says.

This was also the shop’s first experience with a FANUC CNC, in this case, an 0i TF plus control. As he is still becoming familiar with the Swiss-type platform, Phil says perhaps his favorite function on this control is what Nexturn coins the MPG PRO function. This function enables him to execute a program both forward or backward by turning the manual pulse generator handwheel; during automatic operation, either clockwise (forward) or counterclockwise (backward). He can then check for potential errors at specific points in a program without having to wait for the program to complete a full block. (Forward and backward execution within a block are possible.)

The Swiss-type’s Tracer magazine bar feeder that can accommodate 12-foot-long bars includes external LED lights that offer at-a-glance visual monitoring of alarms and remaining bar length.

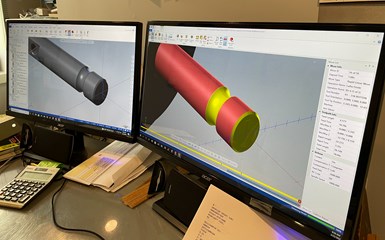

However, in terms of part programming, Hashier Machine stayed with a familiar CAD/CAM platform in Mastercam. It purchased the company’s Swiss module with postprocessor which will enable the shop to more efficiently program more complex parts that would be time-consuming to program by hand and also verify tool paths prior to running jobs. Phil says the software also helps with programming deburring operations using ball mills or chamfer tools to minimize or, ideally, eliminate manual deburring. “This extends cycle times a bit, but we don’t need to have someone available to do it by hand,” he notes. “It also ensures more accurate, consistently sized edge breaks.”

Hashier Machine has used Mastercam for offline programming of its VMCs and recently purchased the Swiss module with postprocessor for its Nexturn. This will enable the shop to more efficiently program more complex parts that would be time-consuming to program by hand and also verify tool paths prior to running jobs.

Lean on the Experts

Moving forward, the shop might add milling machines with five-axis rotary tables as well as twin-spindle lathes, both of which offer the possibility to complete parts in one setup. It might also add another Swiss-type at some point.

But, as Pete points out, every shop can buy the same machine, software and tooling. “The key is tap the expertise of equipment representatives, such as Klaus from Absolute, who can offer guidance as to how to get the most out of that capacity.”

RELATED CONTENT

-

Swiss Rejuvenation Doubles Shop Productivity

As he progressed to CNC Swiss lead and later to his current position as CNC Swiss production supervisor, Darrin Baker helped the Swiss department at Liberty Precision double its productivity, according to his nominator.

-

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

-

When a “Boxy” Part is Machined on a Lathe

South Morgan Technologies has long thrived on its ability to mill prismatic parts on a turning platform. Today, newer technology and techniques enable saying “yes” to that work than ever before.