Connectivity and data collection have become overarching themes in machining and manufacturing. Machine tool OEMs and accessory suppliers continue to build automatic feedback/monitoring capabilities into their equipment to enable shops to have greater control over their shopfloor processes. For example, Hainbuch America Corp. is providing intelligent capabilities on its TopPlus IQ chucks and mandrels. These intelligent workholding devices are integrated with sensors that include part measuring and workholding parameter monitoring capabilities. They are designed to improve workflow by reducing measurement procedure times and decreasing scrap while relaying data to the machine controller for analyzing and process adjustments.

Like the company’s other workholding products, IQ technology was created based on customer input to determine how best to design the devices. “We have to be sure we keep up the integrity of our product as well as adapt it for future growth,” says Hainbuch applications engineer, Jim McCraw. “The IQ chuck/mandrel system is taking that step forward based on customer feedback, including where we place the sensors and what types of data we tried to capture.”

Featured Content

He adds that with the help of customers, the company’s R&D department can test the chucks/mandrels as they develop them while leaving room for future product growth.

Automatic Measuring and Monitoring

It is a fact that machine shops are constantly curious about what’s going on inside of a chuck or workholding device and how it affects the outcome of the workpiece, according to McCraw. Therefore, the automatic measuring and monitoring capabilities of the IQ chucks and mandrels are a natural advancement in the company’s workholding product lineup.

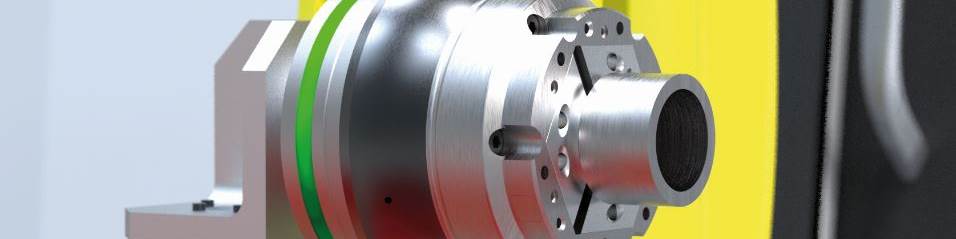

The IQ chuck can be used for measuring the finished workpiece diameter. This data is processed in the controller or in the master computer and is also shown on an LED ring on the chuck. Photo Credit: Hainbuch America Corp.

Traditionally, machine operators needed to pay close attention to process characteristics such as temperature, clamping pressures, rigidity and vibration of the workholding device and workpiece, and document their findings for future use, McCraw explains. Recognizing that potential human error and relying on an operator’s experience could be problematic, Hainbuch engineers designed the IQ workholding devices to automatically — and more accurately — capture this data and transmit it to a database.

“This way, an operator doesn’t have to try to digest what is happening inside the machine and then make decisions about how best to fix it,” McCraw says. With the IQ technology, the critical aspects of the workholding process are programmed into the device and then it outputs accurate information that is reported to the machine control.

The measuring and monitoring possibilities of the TopPlus IQ workholding devices include:

- Clamping and measuring in one step, without using a standalone measuring machine. This characteristic can detect whether the correct diameter was produced in the upstream machining.

- Detecting the workpiece contact through sensors in the basic body and through the three-point part support contact on the workpiece end-stop. The sensors can potentially detect chips on the workpiece end-stop without complex air sensing control with a rotary unit and piping.

- Measuring the temperature of the clamping device. This capability can detect a gradual temperature change caused by the machining process.

- Measuring the RPMs of the clamping device. Knowing the speed can be ideal for condition monitoring for the preparation of RPM-based analysis diagrams, detecting inertia losses.

- Continuous clamping force monitoring directly on the workpiece. Deviation from a calibrated clamping force value is determined this way, but does not provide an absolute measurement. Monitoring can detect if the hydraulic unit/clamping cylinder’s clamping force is suitable for the workpiece. In addition, analysis of the clamping force measurement data enables reliable-process manufacturing and is an important component of maintenance as needed.

Although all this information is possible to collect, many machine shops choose only to gather certain information they feel is most helpful to their applications. This process is a touchless transmission of data and energy between the rotating clamping device and the stator fixed on the headstock.

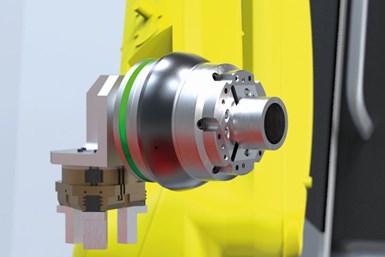

There are three ways the IQ workholding devices can be used for measuring/monitoring: 1) on the machine; 2) when handling the workpiece, and 3) at a measuring station. Photo Credit: Hainbuch America Corp.

Data Distribution

The machine shop can determine what data to collect from the IQ technology and what to do with that data, manually or automatically. For instance, one option is for the IQ chuck/mandrel to display certain information on a graphical user interface or display, which is the data sent directly from the sensors to the operator for him/her to respond. Or the IQ workholding system can be programmed so data can feed back into the machine control and, in response, the machine tool can either make adjustments based on set points or even implement backup tooling if wear points are met. The customer works with the machine builder so they can set up the desired path — or responses — activated through the machine’s control.

“Some shops want the process as automated and remote as possible,” McCraw explains. “It depends on how critical the process is and how much interface they want the operators to have.”

Also, machine shops must consider the type of connectivity loop in which they choose to be engrained for the system, according to McCraw. Companies can not only send data out and share it but also receive shared information.

The IQ chuck can be used on the machine for measuring workpiece diameter, temperature, RPM, workpiece contact and workpiece clamping force. Data is processed in the controller or in the master computer and is displayed on the machine panel. Photo Credit: Hainbuch America Corp.

Data collected by the IQ technology can be kept within the company, within a family of companies, or it can be shared with chosen networks. Data sharing and information privacy must be carefully considered and monitored within the system.

The type of connectivity loop that is chosen determines how the data transmission functions. However, in general, the IQ sensors send information with a Fieldbus system directly to a machine controller or to a graphical user interface. The data can also go to a factory network into a central system that can use that data along with other data sent by other factory workcenters to digitally orchestrate the factories overall processes and output. This central control system can then be interfaced with outside suppliers and resources to use their data to help make adjustments to their internal operations.

“This is where the gateway can expand to the Internet of Things and either share this data with remote resources or take in pertinent shared data from other sources,” McCraw says.

The Operator’s Role

Although the IQ chuck/mandrel system is considered automatic, the system is taught what to do by the operator and is, therefore, not a completely hands-off

This IQ mandrel is for measuring the finished workpiece bore. Data processing occurs in the controller or in the master computer and can be output via a display at the measuring station. Photo Credit: Hainbuch America Corp.

device. Also, depending on the particular application, human input can be very beneficial. For example, an operator must recognize when certain technology is not operating correctly and then intervene when necessary.

In most of these automated systems, customers are striving for control of a process and have consistent reactions to symptoms that need addressing. “So, if they are manually responding to a symptom that has been fed back to them by a sensor, the end effect of the IQ technology is going to only be as reliable as that operator is with correcting the problem,” McCraw explains. But, with automatic compensation within the machine's controller, machines are always making decisions based on facts that have been programmed into them. As much as technology relies on us, we must rely on technology. We are dependent on each other’s accuracy, he adds.

A Little Automation at a Time

Hainbuch’s TopPlus IQ workholding technology enables shops to integrate automated processes as described gradually. One or two sensors, chucks or measuring stations at a time can be integrated into a machine tool so automation does not have to happen all at once.

“I think the more people realize the benefits of implementing the automation on a small scale, the easier it is to justify it with larger investments,” McCraw explains.

These intelligent workholding devices’ benefits are clear, especially for high production applications. The automatic IQ chucks and mandrels increase machine productivity and process capacity, ensure a necessary maintenance schedule, monitor defined clamping forces and document the results to replicate repeat projects.

Hainbuch America Corp. | hainbuchamerica.com

RELATED CONTENT

-

What Is The Best Bar Feed System For Production Turning?

Selecting the right bar feeder can be one of the most important decisions a shop can make. Bar feed systems help improve productivity, throughput and quality, but in order to achieve the most benefit from them it is essential that a bar feed system be matched to the particular needs of the turning operation.

-

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

-

The Effects of Automation on Manufacturing

Companies that are not currently using automation in their manufacturing processes should be considering it.