Editorial, News, and Products

Precision Machining Technology Review May 2021: Workholding

Production Machining’s May Product Showcase includes new workholding equipment from Hainbuch, SMW Autoblok, Schunk, Northfield Precision and Ringspann Corp.

Schunk Rota-M Flex Chuck Jaw Offers Flexible Clamping Capabilities

Chuck jaw has a very long compensation stroke, giving it increased flexibility for clampable workpiece geometries and a wide variety of applications.

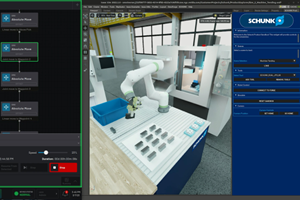

A Hands-On Approach to Cobot Gripping

As humans and robots begin to work closer together, grippers that have the flexibility of the human hand will be more in demand.

Schunk’s Rota NCR-A Six-Jaw Power Lathe Chuck Features Efficient Design

Schunk's power lathe chuck enables maximum roundness

Tendo Platinum Toolholder Works with Machine Spindle

Schunk’s Tendo Platinum toolholder has improved brazing technology by using a brazing and hardening process in the same cycle, which allows for rigid and durable tool clamping.

Tribos-SVL Extensions Combine with Variety of Toolholders

Schunk’s Tribos-SVL toolholder extensions have a slim but robust design that allow machining of workpiece areas that are difficult to access and permit a runout accuracy of less than 0.003 mm.

Rota NCR Six-Jaw Chuck Distributes Clamp Force

Schunk’s six-jaw Rota NCR chuck can be used for thin-walled or deformation-sensitive parts. Rough castings or rings can be centered with minimal distortion to the workpiece.

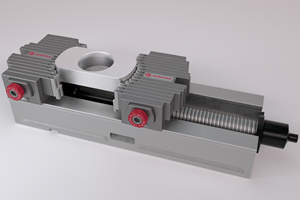

Kontec KSC-F Vise Achieves High Clamping Forces

Schunk’s Kontec KSC-F single-acting clamping vises can be actuated by a standard hexagon connection using either conventional socket wrenches, extensions, or torque wrenches.

Magnos Technology Has Uniform, Deformation-Free Clamping

Schunk’s Magnos magnetic clamping technology is composed of parallel pole, square pole, and radial pole plates that boost productivity by up to 200 percent compared to conventional solutions using parallel pole technology.

Hydraulic Expansion Arbor has Quick-Change Capabilities

Schunk’s hydraulic expansion arbor for customer-specific clamping solutions is for high-precision applications in milling, hobbing, turning, grinding, assembly, inspection, and balancing and now has Vero-S module quick-change capabilities.

Hydraulic Expansion Toolholder Combines Multiple Geographies

Schunk’s Tendo Slim 4ax hydraulic expansion toolholder was designed for axial operations, and can be used to mill close to interfering contours, countersinking, and reaming in five-axis centers and the die and mold industry.

The Tendo E Compact is a Universal Hydraulic Toolholder

Schunk’s Tendo E compact is a universal toolholder for applications such as milling, drilling, and reaming.

Schunk USA to Expand Headquarters

Schunk USA recently held a ground-breaking ceremony to celebrate the start of construction for the expansion of its U.S. headquarters in Morrisville, North Carolina. The expansion will more than double the size of the existing facilities.

PM News: January 2011

Expanding Range of Turning MachinesStar Micronics Co.

Grippers are a Workhandling Concept to Grasp

The cost of machine operation can be expensive, especially when machines must be manned all day long. In our current slow and unpredictable economy, many shops are looking at ways to reduce manpower and increase efficiency by automating their processes.