Rethinking the Grinding Cycle to Optimize Abrasives Cost Savings

Appears in Print as: 'Optimize Abrasives Cost Savings'

For cost savings in grinding, the complete process should be examined, looking for a comprehensive solution using the latest technologies.

#techbrief

The newest abrasive grain blends and bond technologies are a great impetus for manufacturers to rethink grinding strategies to lower the cost of abrasives, but these new technologies alone may not be enough to achieve the advantage being sought.

Grinding wheels are consumable, and using the latest grinding wheels can be an effective strategy to reduce wheel consumption. The goal includes increasing the number of parts between dress cycles or reducing the dress compensation, resulting in more parts per wheel and less annual wheel changes.

Another option to reduce cost is trying to increase wheel life by adjusting or shifting the wheel grade to make it as hard as possible without generating finish issues, such as burn or chatter. Making the wheel harder allows it to hold form better, require less dressing, and last longer, achieving the goal of getting more parts per wheel.

The challenge with both approaches is that they only focus on a very small portion of the total grinding process, addressing only about 3% of the total cost picture. Although wheel consumption can be reduced, overall savings would be minimal.

To maximize the potential improvement and cost savings, it is important to look at the grinding operation as a complete process and offer a comprehensive solution—one that uses today’s newest technologies and other tools available to address overall cost savings goals. This can be accomplished by documenting the whole process (grind parameters, part requirements, and so on), including power utilization with a process monitoring device such as the Norton 4Sight system.

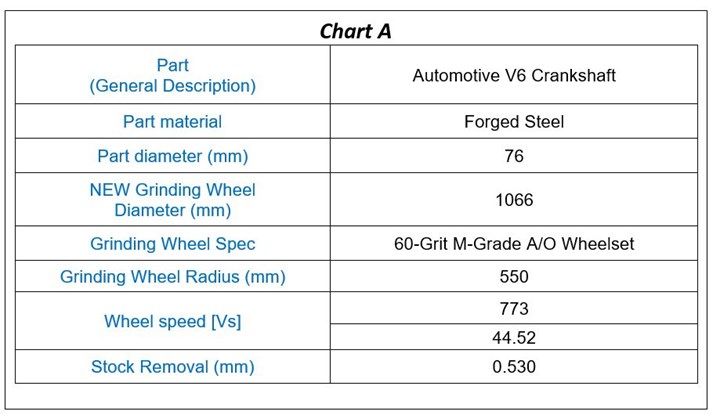

Consider a test application example that uses a multi-wheel set (five wheels) for grinding automotive crankshaft main journals (Chart A). The Norton 4Sight System monitors and records the grind cycle, collects power data and makes it possible to see the process waveform data. Chart B shows the original or existing parameters.

Manufacturers, together with their abrasives suppliers, might begin by examining different wheel specifications and adjusting grade and/or grain blends to try to increase material removal rates (MRR or Q), improve wheel life, and maybe reduce a little cycle time. New abrasives such as Norton Quantum, Targa or other premium blends are designed for high performance in this environment. The Norton Vitrium bond will hold those grains and the wheel form longer, reducing the need to dress and promoting longer wheel life (more parts per dress and/or reduced dress depth).

The benefits of new bonds and grains usually show up on the power monitor as a reduction in grinding energy or power due to the wheel being more efficient, sharper and more open with less bond interaction. They may even offer a slight cycle time reduction (but typically only a few seconds).

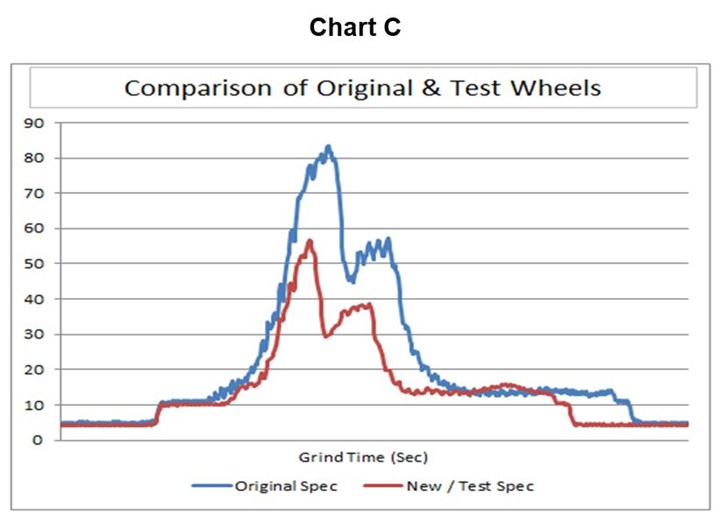

In this automotive test example, a cycle time reduction was also achieved based on the improved cut rate of the premium abrasive and new bond technology illustrated in Chart C. This operation uses in-process gaging, so with the increased material removal rates provided by the new grains, the controller moves the grinder through the program faster as each feed rate endpoint is achieved.

Justifying the Spend

Further, new abrasives and bonds often come with higher prices, so if they only provide a small cycle time reduction, the limited improvement may not justify the move to these newer technologies.

During the automotive example test process, there was between a 3- to 5-second cycle-time savings. This minimal cycle time reduction alone certainly would not justify the higher wheel prices.

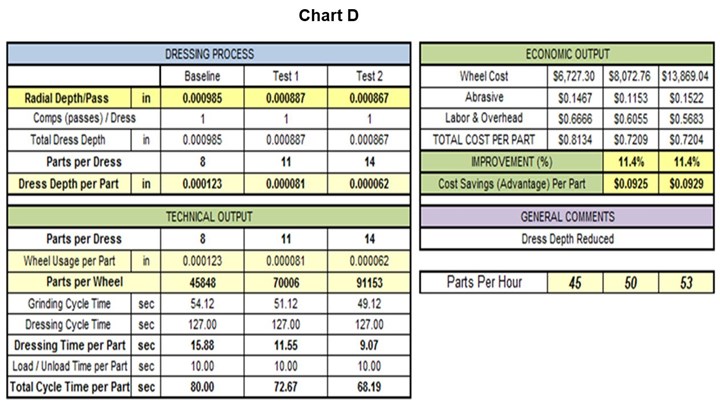

Another step in justifying the wheel price increase is to increase the parts per dress and try to back off the dress depth to maximize wheel life. At this point, the focus is still on the wheel and its directly related savings. By increasing the parts per dress from eight to 11 or 14, the new wheel has a slight cycle time improvement, resulting in less than a 10% cost savings.

New technologies hold the grains and wheel form longer, require dressing less often, and reduce the dress depth. Reducing the dress depth by 10% to 12%, along with the ability to grind slightly faster, provides a cost savings improvement of about 11% (Chart D).

Traditionally, many manufacturers may be satisfied with savings slightly over 10%, but there is still room for improvement to optimize the grinding process.

When grinding with lower power, increasing the feed rates to push the wheel back up to the same power as the original wheel may reduce cycle time further. More jobs per hour equals more savings and further cost reduction.

Although reducing cycle time by pushing the wheel may be effective, it opens the door to residual stress and other metallurgic issues (such as burn), and if the spec is not dialed in correctly, form loss and wheel breakdown become a risk.

Summary of Parameters Changed

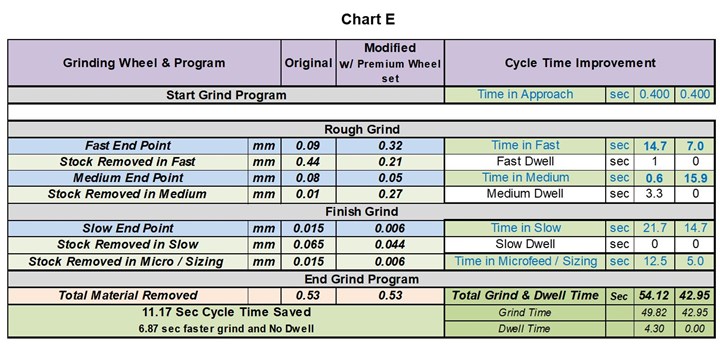

Here is a summary of the grinding parameters that were modified to achieve productivity improvements (Chart E).

- Installed a new wheel specification and experienced a slight cycle time reduction

- Increased parts per dress, resulting in longer wheel life

- Reduced dress depth/compensation to further extend wheel life

- Modified the grind program to balance out the power curve and optimize wheel performance:

- Moved approach end point closer to the part to start the grind sooner

- Moved fast end point out to end fast grind sooner

- Moved medium end point in to spend more time in medium feed (grinding longer at this rate uses less power/energy to grind)

- Moved slow end point in to ensure reaching size without using micro or sizing feed (more material removed in medium feed, spending less time in slow to make final size)

- Eliminated or significantly reduced dwell throughout the program

Summary of Benefits Gained

- Increased wheel life equals more parts per wheel, less wheel-change downtime

- Shorter grinding cycle equals more jobs per hour/more productivity

- More balance power curve equals more consistent grind with a lower chance of or lower levels of residual stress

More Options and Strategies

The modified, optimized grind program results in a significantly different power curve. The power curves in the redesigned program have a faster grind (shorter grind cycle) and a far different form and reduced power. A lot of options are, therefore, available to further optimize the grind cycle. It also doubled the cost savings by cutting the cycle time down and increasing the parts per hour by 31% to 40% (14 to 18 extra jobs per hour).

Further, if residual stress becomes a major concern while working through the grinding strategies, other parameters can be used to fully optimize the new wheel specification and maximize savings to ultimately achieve a 34.2% cost savings and increase productivity in parts per hour by 48.89% (22 more parts per hour).

There are still additional strategies available to optimize the grinding process, and close communication between manufacturers and their abrasives suppliers is key to satisfying the most important goals. These strategies include:

- Leave the power curve as it is now, grind with the lower power/energy and create parts with lower residual stress.

- If stress isn’t an issue, change the program end points back and push the feed rates to bring the power back up to where it was originally to further cut cycle time (although the residual/grinding stress will also increase).

- Keep working with dress parameters (PPD, depth, traverse rates, and so on) to improve wheel life. If the wheels stay open and cutting, the result may be some fractional cycle time savings and further increased productivity.

- Do nothing more if satisfied with the results.

The Big Picture

By using the newest grains and bonds available and following strategies that apply to the entire grinding process, manufacturers can change how they grind and save abrasives costs. The complete abrasive solution is not one that simply upgrades abrasive technology. It is one that fully utilizes those new technologies to achieve and exceed customer expectations.

Norton | Saint-Gobain | nortonabrasives.com

About the Author

Dave Goetz is a corporate application engineer at Norton | Saint-Gobain Abrasives. Norton offers a portfolio of grinding, cutting, blending, finishing and polishing solutions for all markets, materials and applications.

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Diamond Lapping and Lapping Plate Control

The word “diamond” brings the word “expensive” to mind. But when it comes to lapping with diamond superabrasives, start thinking “low”—as in lower slurry consumption, lower slurry cost per hour, lower sludge generation, lower cycle time, lower reject rates and fewer process steps.

-

Adding 5-Axis Capability to a 3-Axis CNC Mill

This attachment provides shops using thee-axis machining centers the option of on-demand four- and five-axis machining.