Every month, we’re putting together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For September, we focused on cutting tools — one of the most essential technologies for precision machining.

PM’s September Cutting Tools showcase includes a tool designed for automatic back spotfacing using compressed air activation; a CVD diamond-tipped tool system for drilling and countersinking operations for solid carbides and sintered ceramics; multifunctional tools for drilling, with stationary or rotating tools or for turning face, inner and outer contours; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s August’s Technology Review.

Click on each link below to read the full product post:

Photo Credit: Heule Precision Tools

Heule Precision Tools highlights its newly enhanced BSF Air tooling, which it says is the first tooling system designed for automatic back spotfacing using compressed air activation. Designed for applications where through coolant activation is not possible, the Heule BSF Air Tool delivers precision back spotfacing using shop air to activate the tool, thus eliminating the need for through spindle coolant.

Horn’s DDHM is a CVD diamond-tipped tool system designed to provide cost-effective drilling and countersinking operations for solid carbides and sintered ceramics with a hardness of up to 3,000 HV. This drilling system further expands the company’s range of products for machining fully sintered carbides.

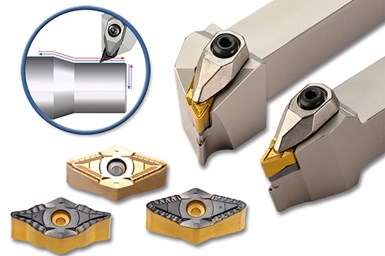

Ceratizit’s multifunctional EcoCut tools are designed to help manufacturers enhance their quality, productivity and output — whether for drilling, with stationary or rotating tools or for turning face, inner and outer contours. These tools are available in three versions: EcoCut Classic, EcoCut Mini and EcoCut ProfileMaster which address various diameters and bores for high performance in steel, stainless steel and high-temperature materials.

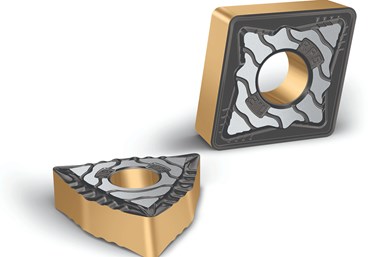

Photo Credit: Ingersoll Cutting Tools

Ingersoll Cutting Tools says its SuperTurnZ inserts are an innovative system for multidirectional turning which uses the front and back cutting edge of a four-corner insert in a single tool. The inserts are said to be a productive alternative to conventional turning where 80-degree and 35-degree corner inserts are fed in the same direction.

Schwanog’s insertable form tool system is designed to offer superior quality and high efficiency in the manufacture of precision parts for industries such as medical, automotive, aerospace and others. The insertable tools can be applied to a variety of applications, including OD and ID grooving, form drilling, thread whirling, single-point threading, turning, milling, broaching of serrations, shaving, skiving and polygon turning.

Walter’s Tiger·tec Gold inserts are specially designed for turning operations in all steel applications, including low carbon steels and various alloy steels. The company says a key feature of these inserts is a CVD coating layer that enables process reliability for improved performance and longer tool life. The layer structure involves a highly textured MT-TiCN (titanium carbonitride) layer which is said to reduce flank face wear and increase toughness due to its multilayered elastic structure.

Landscape Source: Ceratizit

RELATED CONTENT

-

Find the definition, types and advantages of both CNC collets and chucks for workholding as well as the best applications for each, in this article.

-

Production Machining’s Cutting Tools showcase includes Ceratizit, Suhner, Horn, Sandvik Coromant, Ingersoll and Allied Machine & Engineering.

-

High-performance milling cutters combine high cutting data with long tool life and efficiency, but certain factors must be considered when selecting tools for different machining tasks.