Every month, we’re putting together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For August, we focused on Automation & Robots that will be highlighted at IMTS 2022.

PM’s August Automation & Robots showcase includes a magazine bar feeder that enables unattended operation; a cobot series which is easy to use and integrate into users’ manufacturing processes; an automatic bar feeder which can stage up to 1,430 lbs of barstock for long unattended and lights-out production; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s July’s Technology Review.

Click on each link below to read the full product post:

Photo Credit: Edge Technologies

The Commander 8-80 from Edge Technologies is a compact, magazine-style bar feeder that features an 8- to 80-mm bar diameter capacity range for feeding 6 ft. and 12 ft.-long round, square, hexagonal and shaped bar stock into fixed headstock CNC lathes. With a large magazine capacity enabling unattended operation, the Commander 8-80 offers the advantage of automatic bar loading with a small footprint.

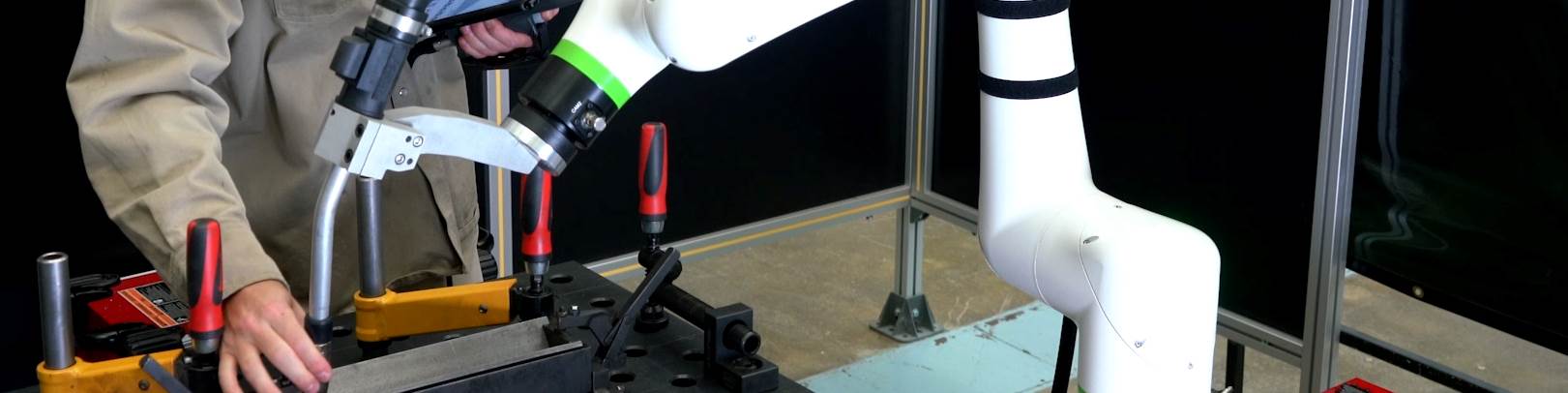

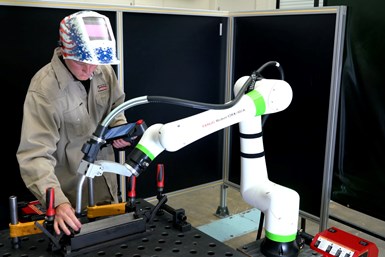

Photo Credit: Absolute Machine Tools

Absolute Machine Tools and Productive Robotics says their OB7 Cobot Series are easy to use and integrate into users’ manufacturing processes. Maximizing the safety, convenience and productivity provided by collaborative robot (cobot) technology, the four different OB7 cobots in the series are engineered to handle a variety of payloads and sizes while accomplishing simple to complex tasks.

Photo Credit: LNS North America

LNS North America’s LNS Quick Load Servo 105 automatic bar feeder is designed to precisely load 1/4"-4 1/8" (6 mm to 105 mm) diameter, spindle length bars with overall lengths of 11" to 63" (not to exceed the combined length of the headstock, chuck and actuator). Model 105-L (extra-long pusher) loads bars with diameters of 3/8"-4 1/8" (9.5 mm to 105 mm).

Photo Credit: FANUC America Corp.

FANUC America Corp., a developer of CNCs, robotics and robomachines, has expanded its lineup of its CRX Cobot series. Joining FANUC’s CRX collaborative robots series is the CRX-5iA, CRX-20iA/L and CRX-25iA. The CRX cobots complement FANUC’s existing line of CR and CRX cobots with a total of 11 model variations able to handle products from 4 to 35 kg. The cobots are suitable for a variety of manufacturing settings and applications.

Photo Credit: Universal Robots

Universal Robots’ UR20 cobot boasts an all-new design based on Universal Robots’ experience in highly refined engineering. The UR20 features an entirely new joint design that is said to enable even faster cycle times, as well as the ability to handle heavier loads. Its 1,750-mm reach has been designed to work to the full height of the standard Euro-pallet, which the company says will transform the way businesses package and palletize.

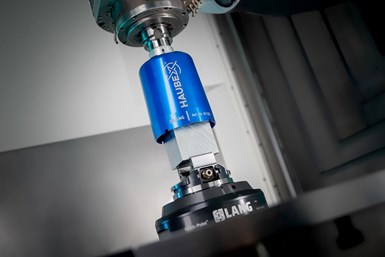

Photo Credit: Lang Technovation

Lang Technovation says its Haubex is a flexible and cost-effective automation solution for small batches from batch size 2 that transforms the tool magazine into an automation system. The heart of the system is a workholding hood, which serves as a carrier system for the clamping device and the workpiece blank and is stored in the tool magazine.

RELATED CONTENT

-

Alexandria Industries struggled with its first robotic machining cell. However, the aluminum extrusion components manufacturer — now with more than 20 robots — discovered that by simplifying and standardizing its automation strategy, it could reap the benefits of unattended machining even for relatively low batch sizes.

-

A free online loan prequalification tool currently offered in Colorado with the potential for introduction to other U.S. markets can enable manufacturers to more easily finance new technologies including automation equipment.

-

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.