The precision machining industry faces a relentless challenge to constantly find new ways of increasing productivity, while ensuring the continued production of high quality components. Highly efficient tooling and machining methods involve raising feed rates, boosting cutting speeds and increasing the depth of cuts – all while maintaining the all-important quality.

Cutting tool manufacturers are rising to this challenge. This month, our Technology Showcase is highlighting some of the product information that PM received from supplier companies. For April, we focused on cutting tools, including standard coated-carbide ISO-P steel insert grades for common steel turning operations; drilling units customized for particular operations; IG6 and SG3 coatings for cartridge tooling systems; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s March Technology Review.

Click on each link below to read the full product post:

Ceratizit has three new standard coated-carbide ISO-P steel insert grades for common steel turning operations which are said to provide up to 20% longer tool life when compared to previous generation grades. The inserts are highly engineered for increased productivity and feature advanced substrates, geometries and Ceratizit’s Dragonskin multilayer coating for lower heat and less tool wear, the company says.

Suhner’s Economaster drilling line offers inline vertical configuration and multiple spindle heads for medium-duty production drilling, with many other available spindle options and toolholders. The drills are suited for multiple materials, including light metal, wood, composite, plastic and foam.

Horn has developed hard and tough coatings with homogeneous structures designed to offer improved cartridge tooling system performance. The company says its IG6 and SG3 high-performance coatings can extend the service life of carbide tools by over 1,000%. These coatings are less than 0.005-mm (0.0002") thick.

Photo Credit: Sandvik Coromant

Sandvik Coromant offers two microdrill families specifically designed for precision machining. The CoroDrill 462 with -XM geometry and the CoroDrill 862 with -GM geometry support industries with high demand for small part manufacturing, including medical, automotive, electronics and aerospace.

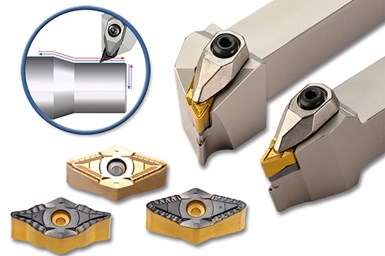

Photo Credit: Ingersoll Cutting Tools

Ingersoll Cutting Tools says its SuperTurnZ inserts are an innovative system for multidirectional turning which uses the front and back cutting edge of a four-corner insert in a single tool. The inserts are said to be a productive alternative to conventional turning where 80-degree and 35-degree corner inserts are fed in the same direction. Instead, these inserts use all four directions available on a conventional two-axis lathe (+Z, -Z, +X, -X) to maximize material removal.

Photo Credit: Allied Machine & Engineering

Allied Machine and Engineering’s 465 (464) series of Wohlhaupter fine boring heads are internally balanced and include 3ETech digital adjustment as well as analog vernier scale adjustment. One 3ETech digital readout can be used on multiple adaptable 3ETech boring head tools, including VarioBore, 538 (537) large diameter cassettes, 465 (464) fine boring heads and custom tooling solutions.

RELATED CONTENT

-

High-performance milling cutters combine high cutting data with long tool life and efficiency, but certain factors must be considered when selecting tools for different machining tasks.

-

Few materials have had a greater impact on our economy and industrialized culture than cemented tungsten carbide.

-

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.